Pneumatic installation – Festo Линейно-поворотный зажим CLR User Manual

Page 27

CLR−...

Festo CLR−... 0912d English

27

Pneumatic installation

Please note

The clamping finger from Festo matches optimally the CLR−... and does not

require any air restriction.

S Note that if user−made clamping fingers are used, the mass moment of inertia

must be calculated.

A higher mass moment of inertia than that specified for the clamping finger

set from Festo requires a reduction in the stroke time of the CLR−... by the use

of one−way flow control valves.

The dimensions of the cone and the diagrams for determining the stroke time

as a factor of the mass moment of inertia can be found in the Festo cataĆ

logue.

S

Remove the adhesive labels on the compressed air connections.

S

Check to see if accessories are required as shown in the following table.

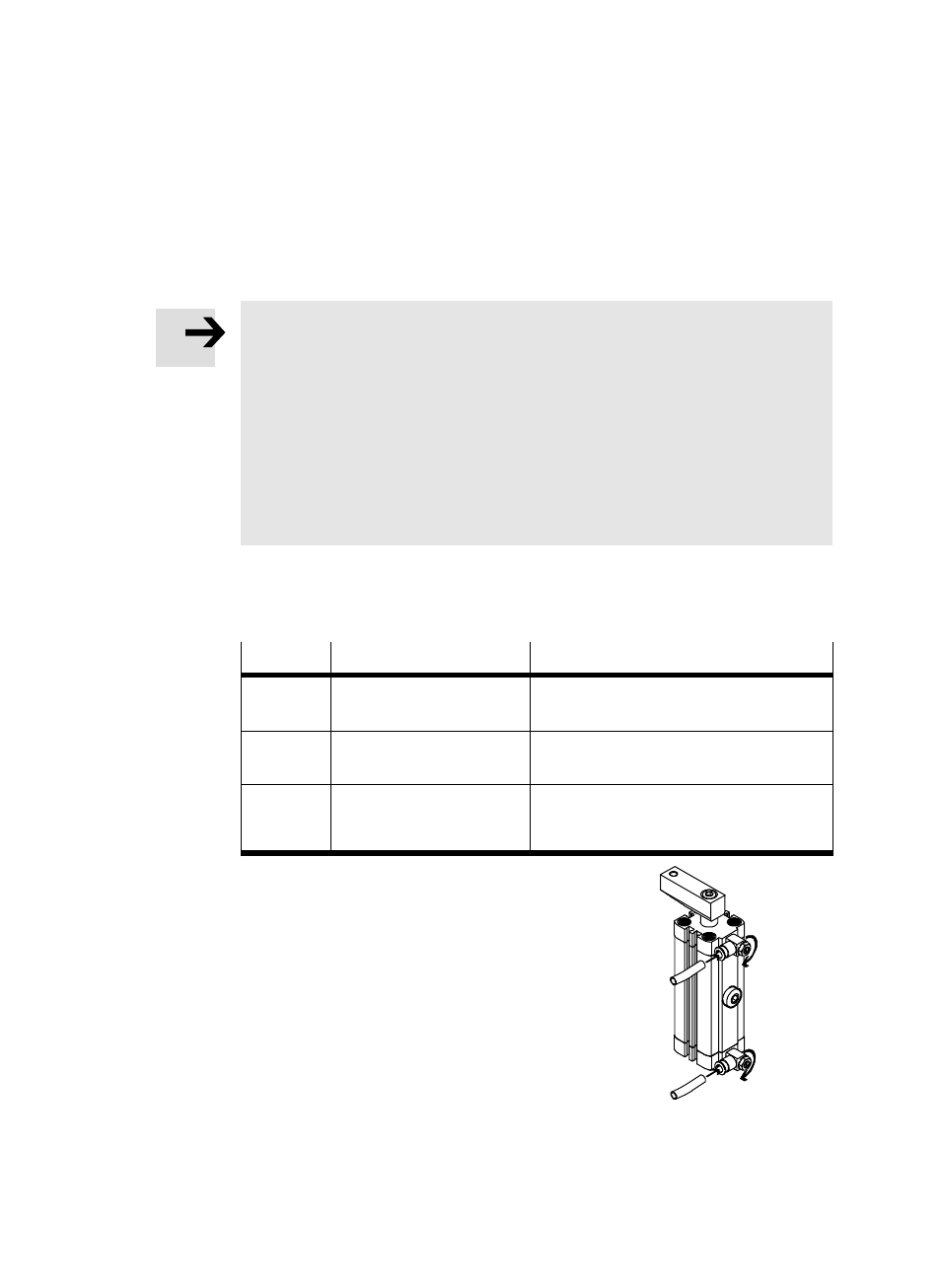

Type

Designation

Function

HGL−...

Non−return valves with

closed−loop control

If there is a pressure falure, the pressure in

the piston chamber will be retained.

GRLA−... /

GRLZ−...

One−way flow control

valves

The piston speed can be modified.

VZS−...

Compressed air reservoir

Fluctuations in pressure will be reduced in

the downstream−switched compressed air

string.

Fig. 15

S

Use short tubing lines for your

application.

Short lines optimize the pressurisation

time.

S

Screw the one−way flow control valves of

type GRLZ−... or GRLA−... into the comĆ

pressed air connections.

S

Connect the tubing of the CLR−... to the

compressed air connections.

Fig. 16