Figure 2-1a – West Control Solutions MRC 9000 User Manual

Page 20

Section 2

2-1

Edition 3

Rev G

Section 2 - Installation and Wiring

Read these instructions carefully before proceeding with installation and operation. Electrical code requirements

and safety standards should be observed. Installation should be performed by qualified personnel.

2.1 MOUNTING (Panel and Surface described below, pipe - to be determined)

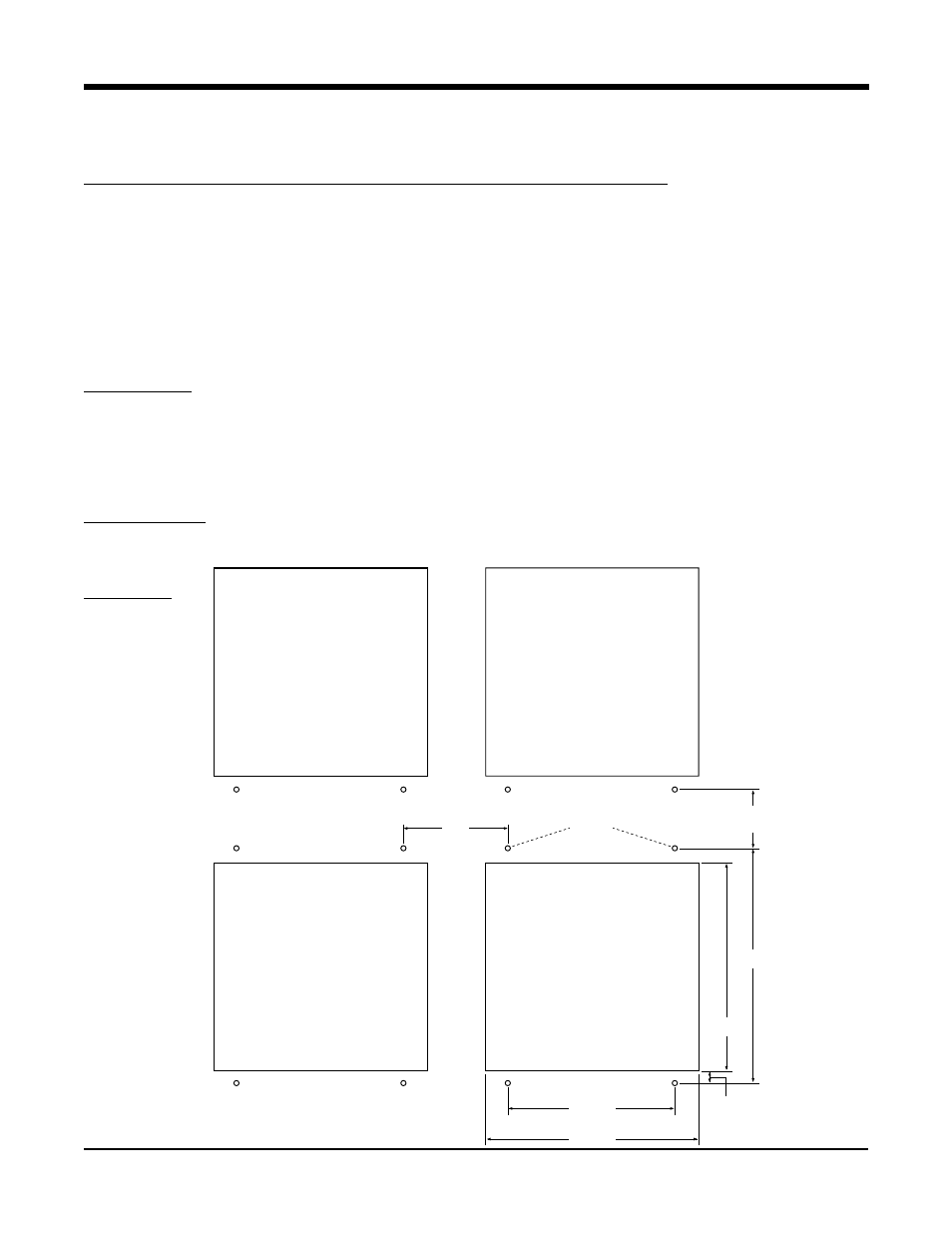

Figure 2-1A and 2-1B (below and page 2) shows an installation view and physical dimensions for a panel

mounted instrument. The panel where the instrument will be mounted must provide rigid support for the approxi-

mately 25 pound instrument. Adjacent instruments may be mounted within a minimum of 2 inches horizontally

and 1 inch vertically, providing that proper panel support is supplied.

Panel Mounting Hardware Required: (not provided with instrument)

(4) #10 flat head bolts with nuts

(4) lock washers

Panel Mounting

1. Cut panel opening to the dimensions illustrated in Figure 2-1A (below).

2. Pre-drill four 3/16 dia. holes for mounting or use the drill template molded into the case after inserting the

instrument into the panel.

3. Insert the instrument in the panel opening. Firmly fasten the instrument to the panel using the nuts, bolts and

lock washers.

Surface Mounting

Install the mounting brackets, ordered separately, on the vertical sides of instrument housing. Use the brackets to

fasten the instrument to the surface. Hardware recommended - #10-24 SCRs.

FIGURE 2-1A

(MIN. HORZ. SPACING)

6.156"

(156.36mm)

(MIN. VERT. SPACING)

3.600"

(91.44mm)

3/16" DIA.

12.700"

(322.58mm)

14.180"

(360.17mm)

10.000"

(254.00mm)

12.700"

(322.58mm)

0.7"

(17.78mm)