2 piping for the calibration gas, 3 piping for the reference gas inlet, 4 piping for the reference gas outlet – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 53

IM 11M13A01-04E

4-3

4. Piping

4.1.2

Piping for the Calibration Gas

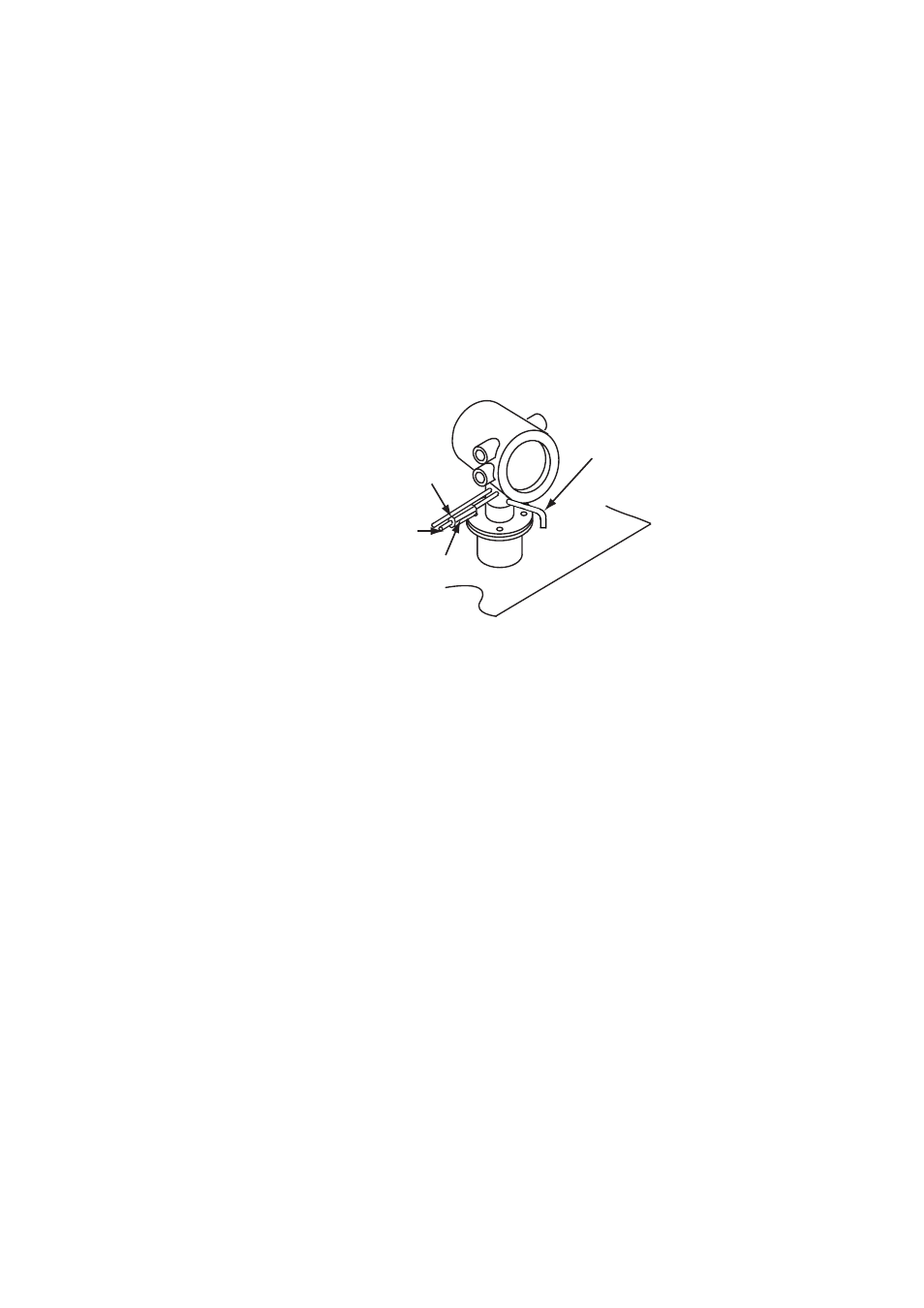

This piping is to be installed between the zero gas cylinder and the ZA8F flow setting

unit, and between the ZA8F flow setting unit and the ZR202S analyzer.

The cylinder should be placed in a calibration gas unit case or the like to avoid any

direct sunlight or radiant heat so that the gas cylinder temperature may not exceed 40˚C.

Mount the pressure regulator (recommended by YOKOGAWA) on the cylinder.

Mount the stop valve or the check valve (recommended by YOKOGAWA) through the

nipple (commercially available) at the calibration gas inlet of the equipment as illus-

trated in Figure 4.8. (The stop valve or the check valve may have been mounted on the

equipment when shipped.) Connect the flow setting unit and the analyzer to a 6mm

(O.D.) x 4mm (I.D.) (or nominal size 1/4 inches) or larger stainless steel pipe.

F4.8E.EPS

Stop valve or check valve

Piping for the reference gas

6mm (O.D.) by 4mm (I.D.)

stainless steel pipe

Piping for the calibration gas

6mm (O.D.) by 4mm (I.D.)

stainless steel pipe

Piping for the reference gas outlet

6mm (O.D.) by 4mm (I.D.)

stainless steel pipe

Figure 4.8 Piping for the Calibration Gas Inlet

4.1.3

Piping for the Reference Gas Inlet

Reference gas piping is required between the air source (instrument air) and the flow

setting unit, and between the flow setting unit and the analyzer.

Insert the air set next to the flow setting unit in the piping between the air source and

the flow setting unit.

Use a 6mm (O.D.) x 4mm (I.D.) (or nominal size 1/4 inch) stainless steel pipe between

the flow setting unit and the analyzer.

4.1.4 Piping for the Reference Gas Outlet

If ZR202S is exposed to rain or water splash, connect the pipe outlet on downward.