4 replacement of flame arrester assembly – Yokogawa Integral Oxygen Analyzer ZR202 User Manual

Page 149

IM 11M13A01-04E

11-7

11.

Inspection and Maintenance

Replacement of heater strut assembly

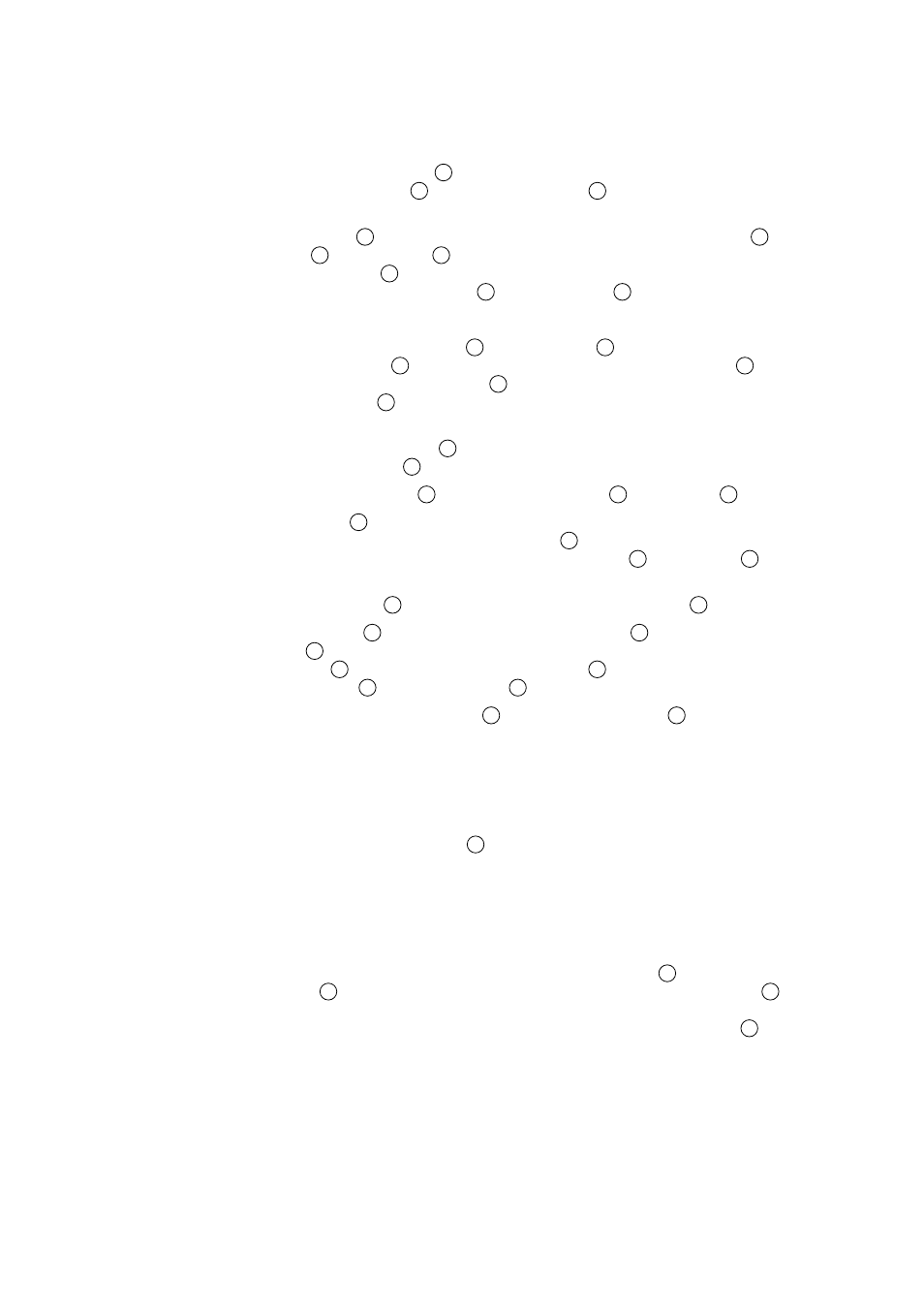

Refer to Figure 11.4 as an aid in the following discussion.

Remove the cell assembly

11

, following Section 11.1.2, earlier in this manual.

Remove the four bolts

10

to remove the converter

16

. Then remove the three

connectors to which lead wire from the heater and thermocouple is connected.

Loosen screw

19

until it can be removed from hole in heater strut assembly

23

plate.

O-ring

18

prevents screw

19

from dropping out. The O-ring does not loosen and

remove the screw

8

with a special wrench (part no. K9470BX or equivalent) and then

remove the heater strut assembly

23

from the detector

24

.

To reassemble the heater strut assembly, reverse the above procedure:

Insert the heater strut assembly

23

into the detector

24

, while inserting the calibration

pipe in the detector

24

into the heater section in the heater strut assembly

23

as well as

in the bracket hole. Coat the screw

8

with grease (NEVER-SEEZ: G7067ZA) and

tighten the screw

8

with a special tool (part no. K9470BX or equivalent) with a

tightening torque of 12N•m

Ϯ 10%.

Next, to install the O-rings

22

on the calibration-gas and reference-gas pipes, disas-

semble the connector

13

in the following procedure:

First, remove the screw

25

and then remove the plate

17

and two caps

20

.

If the O-ring

22

remains in the hole, pull them out from the back. Pass the heater and

thermocouple lead wire through the connector

13

. Also, pass the calibration-gas and

reference-gas pipes through the opening of the connector

13

. If the O-ring

22

fails,

replace it with a new one.

Push the two caps

20

into the associated opening of the connector

13

.

Insert the plate

17

, aligning it with the groove of the cap

20

, and tighten it with the

screw

25

. If you attempt to insert the calibration-gas and reference-gas pipes into the

connector

13

without disassembling the connector

13

, the O-ring may be damaged.

Tighten screw

19

to secure connector

13

.

When installing the cell assembly

6

, replace the metal O-ring

7

with a new one.

11.1.4

Replacement of flame arrester assembly

If it takes longer for the analyzer to return to read the concentration of a sample gas

after calibration, the flame arrester may have become clogged. Inspect the flame arrester

and if necessary, clean or replace it.

Set the flame arrester assembly

1

in place using a special pin spanner (with a pin 4.5

mm in diameter: part no. K9471UX or equivalent). If a flame arrester assembly that has

already been replaced once is used again, apply grease (NEVER SEAZE: G7067ZA) to

the threads of the flame arrester assembly.

If the flame arrester assembly is clogged with dust, replace it with new one or wash it.

In case of the ATEX flameproof model (MS Code: ZR202S-A-...) or IECEx flameproof

model (MS Code: ZR202S-D-...), the flame arrester assembly

1

is bonded to the

detector

24

with an ceramic adhesive. To remove the flame arrester assembly

1

, crack

the hardened adhesive on the joint by tapping it with a flat head screwdriver and a

hammer or appropriate tools. After reattaching the flame arrester assembly

1

, apply a

small amount of ceramic adhesive (P/N G7018ZA), with a diameter not exceeding 10

mm, to the joint part. Be careful not to allow the ceramic adhesive to enter between the

female and the male screws. Before applying, stir the ceramic adhesive thoroughly. The

ceramic adhesive should be stored in a cool, dark place and has a shelf life of 6 months

from the date of shipment.