A8.2.11 reset of reference value, A8-13 – Yokogawa EJX930A User Manual

Page 157

A8-13

IM 01C25T02-01E

Move the threshold toward the white.

• It becomes increasingly likely to give an alarm

due to the disturbance from environment

change.

• If flow/differential pressure is below DIAG_LIM

[10] or exceeds DIAG_LIM [9], pressure

fluctuation is likely too small or too large to

detect the blockage.

Move the threshold toward the black.

• It enables to be insusceptible to disturbance

such as environment change and to detect the

blockage easier.

• It becomes giving an alarm of the blockage after

the blockage has been progressed.

The default values at the factory setting are the

values of DIAG_LIM [1] to [8] shown in Table A8. 2.

Change the threshold value to solve your problem

according to the above image

(1) Set “Stop” to DIAG_MODE.

(2) Change the unsuitable value of DIAG_

LIM corresponding to the each blockage

detection.

Note:Set to “Calculation” after setting the parameters.

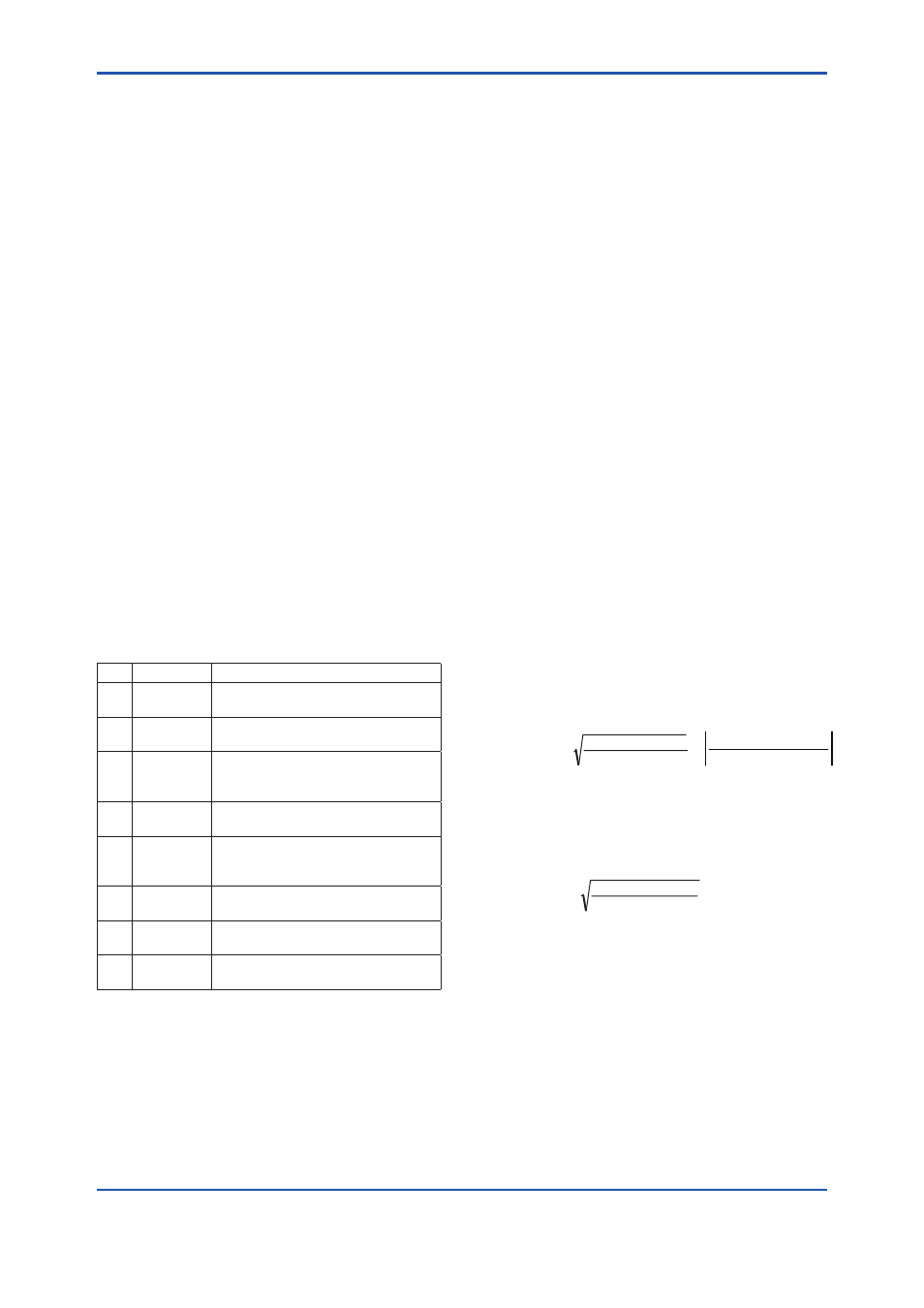

DIAG_LIM

#

Parameter

Threshold value

[1] fdpmax

Threshold to detect “A Blocking” by

using

RATIO_FDP

[2] fdpmin

Threshold to detect “B Blocking” by

using

RATIO_FDP

[3] fsplmax

Threshold to detect “Large

Fluctuation of Low Side” by using

RATIO_FSPL

[4] fsplmin

Threshold to detect “Low Side

Blocking” by using

RATIO_FSPL

[5] fsphmax

Threshold to detect “Large

Fluctuation of High Side” by using

RATIO_FSPH

[6] fsphmin

Threshold to detect “High Side

Blocking” by using

RATIO_FSPH

[7] blkfmax

Threshold to detect “High Side

Blocking” by using

VALUE_BLKF

[8] blkfmin

Threshold to detect “Low Side

Blocking” by using

VALUE_BLKF

A8.2.10.2 Sampling Period

If fluctuating around the threshold value, an

alarm may be often generated. When the above

phenomenon happens, the sampling time (DIAG_

PERIOD) can be changed as as to enhance the

accuracy of the blockage detection.

The longer the sampling time, better the expected

accuracy.

(1) Set “Stop” to DIAG_MODE.

(2) Enter the value to DIAG_PERIOD within

the range of 20 to 65535 (seconds).

Note: Set to “Calculation” after setting the parameters.

Also, the accuracy can be improved by increasing

the number of DIAG_COUNT.

A8.2.10.3 ILBD Range Setting

When the VALUE_DPAVG is less than the value of

the DIAG_LIM [10] or exceeds the value of DIAG_

LIM [9] shown in Table A8. 2, EJX gives an alarm of

“Outside Diagnosis Range”.

If flow/differential pressure is less than the default

threshold value of DIAG_LIM [10], pressure

fluctuation is not large enough to detect the

blockage. To prevent the fault blockage detection,

the threshold value should be changed to larger

value.

(1) Set “Stop” to DIAG_MODE.

(2) Enter the value to DIAG_LIM [10].

Note: Set to “Calculation” after setting the parameters.

A8.2.10.4 COMP_FLG

When “Compensation” is selected in COMP_FLG,

RATIO_FDP is compensated by following formula

and used as treatable monitoring value, CRATIO_

FDP.

X REFERENCE_DPAVG

CRATIO_FDP =

VALUE_DPAVG

VALUE_FDP

REFERENCE_FDP

On the other hand, if the compensation is not

necessary, “Non-compensation” is selected in

COMP_FLG and RATIO_FDP is used as NRATIO_

FDP.

=

NRATIO_FDP

VALUE_FDP

REFERENCE_FDP

A8.2.11 Reset of Reference Value

When there are large flow change or the change of

fluid under the measured process conditions, obtain

the reference value again.

If flow change by a comparison of the reference

value is ±25% or more, you need to obtain the

reference value again.