4 internal inspection – IAI America ISWA User Manual

Page 46

38

10. Maintenance/Inspection

10.4

Internal Inspection

Turn off the power supply, remove the screw cover and have a visual inspection.

Please check the following items in the internal inspection.

Main body

Loose mounting bolts

Guide Area

Lubricant condition and dirtiness

Ball Screw Area

Lubricant condition and dirtiness

Check the internal condition by visual. Check inside for foreign substance such as dust and the condition

of lubricant.

Even if the grease has turned brown, the lubricant condition is good as long as the track surface is glossy

and looks wet. In the case the grease is dirty with dust and gloss is lost, or it is worn out after a long term

of use, supply the grease after conducting cleaning to each part.

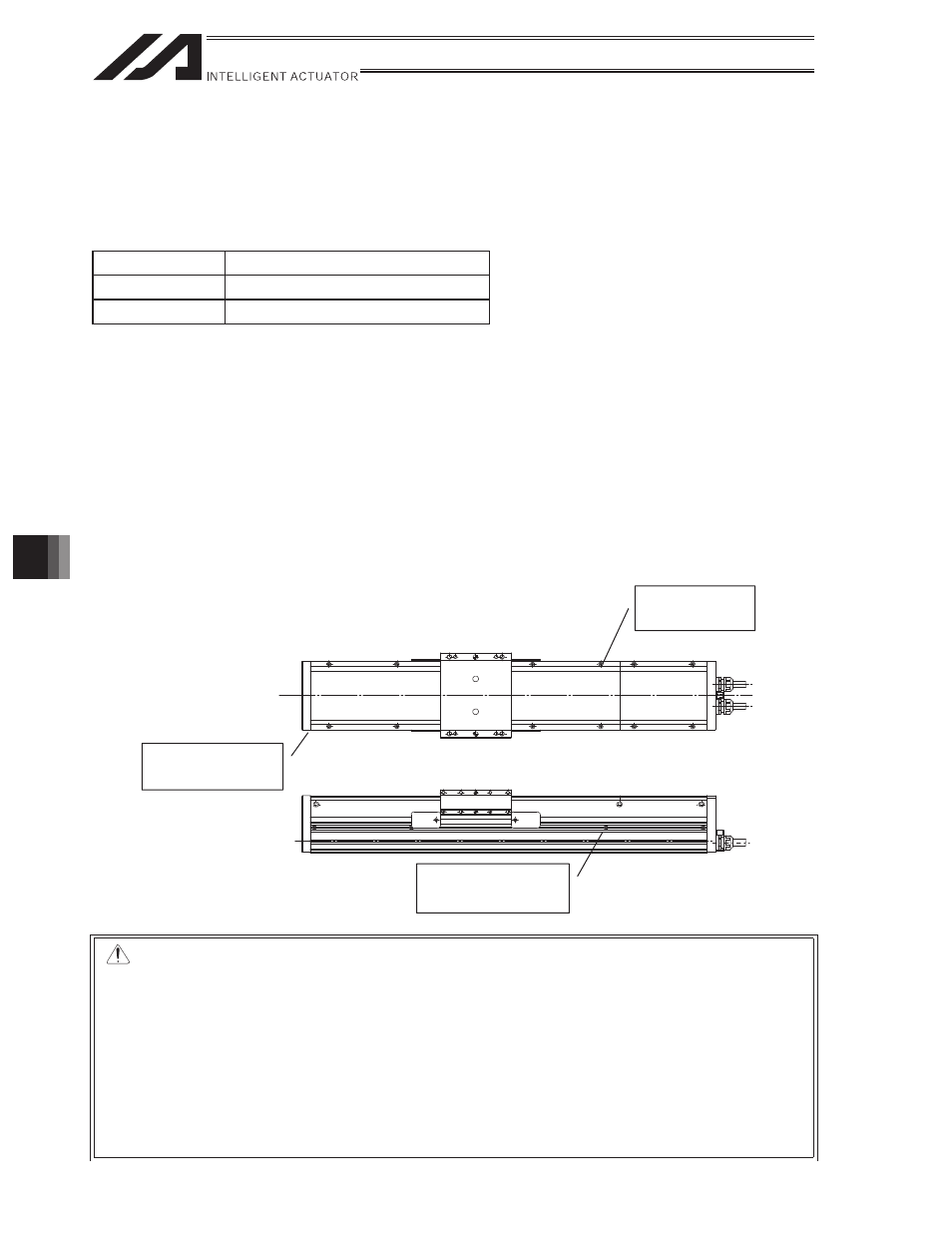

Shown below is the process of internal inspection.

(1) Use a 2.5mm hex wrench to remove the screw cover on the top.

(2) Conduct the internal inspection.

5HDVVHPEOHLQUHYHUVHRUGHUDIWHULQVSHFWLRQLV¿QLVKHG

CAUTION :

x Do not remove the front cover since it has a function to support the ball screw.

The front cover being off the adjusted position may make the shaft position

misaligned, which may cause resistance in operation, shorten the life of each

part, or cause an occurrence of abnormal noise.

x Side cover retains a sealing. Do not loosen the screws.

Once the screws are loosened, it affects the function of the sealing and may allow

water to get in.

x If an abnormality such as crack or peel-off is found on the sealing on the back side

of the screw cover, replace it accordingly.

Attachment screw

for screw cover

Do not loosen screws

on the side cover

Do not remove the

front cover