Maintenance/inspection, 1 inspection items and intervals, 2 visual inspection of the machine exterior – IAI America ISWA User Manual

Page 45: 3 external cleaning

37

10. Maintenance/Inspection

10. Maintenance/Inspection

10.1

Inspection Items and Intervals

10.2

Visual Inspection of the Machine Exterior

Please check the following items in the visual inspection.

Main body

Loose mounting bolts

Cables

Damage to cables, connection of connectors

General

Noise, vibration

10.3

External Cleaning

x Clean the exterior surfaces from time to time.

x Wipe off dirt with a soft cloth.

x There may be a case that the base oil of the grease is come out of the actuator housing.

Wipe it off with a soft cloth.

x Do not spray compressed air on the actuator that might force dust into the crevices.

x Do not use petroleum-based solvents as they damage plastic parts and painted surfaces.

x If the unit gets badly soiled, moisten a soft cloth with a neutral detergent or alcohol and wipe the soiled

area gently.

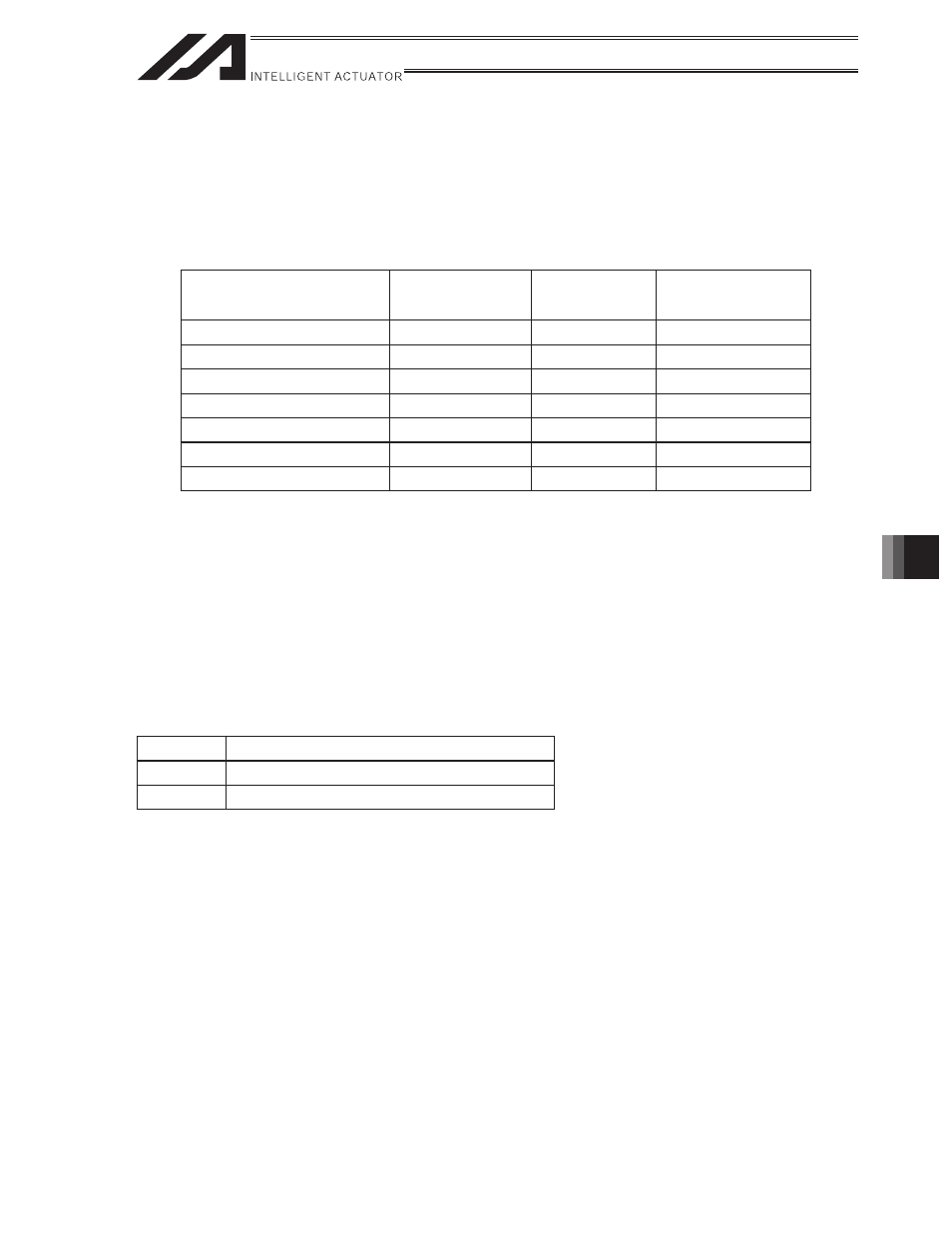

Visual inspection of

machine exterior

Interior check

Lubrication

*3

At start of operation

ż

After 1 month of operation

ż

Every 3 months

ż

ż

*1

After 6 months of operation

ż

ż

ż

*2

After 1 year of operation

ż

ż

ż

Every 6 months thereafter

ż

Every year thereafter

ż

ż

ż

*1

Life is shorter compared to other types of grease. Have an inspection more often than usual.

6XSSO\JUHDVHLIDGHJUDGDWLRQRIJUHDVHLVFRQ¿UPHGLQDQLQWHUQDOLQVSHFWLRQ

*3

Continuous back and forth operation within a distance less than 30mm may cause wear of grease.

It is recommended to have 5 rounds of back and forth operation in a distance more than 50mm after

every 5,000 to 10,000 rounds of the short distance operation. A layer of the grease will recover.