Programming language, Prosec t2n – Toshiba T2N User Manual

Page 255

5. Programming Language

242

PROSEC T2N

DIAG (A) (B)

DIAR (A)

STLS

STLR

(A) CLDS

(A) CLNBD (B)

(A) DRUM (n)

(Β) →

(C) (m)

(A) CAM (n) (B)

→

(C)

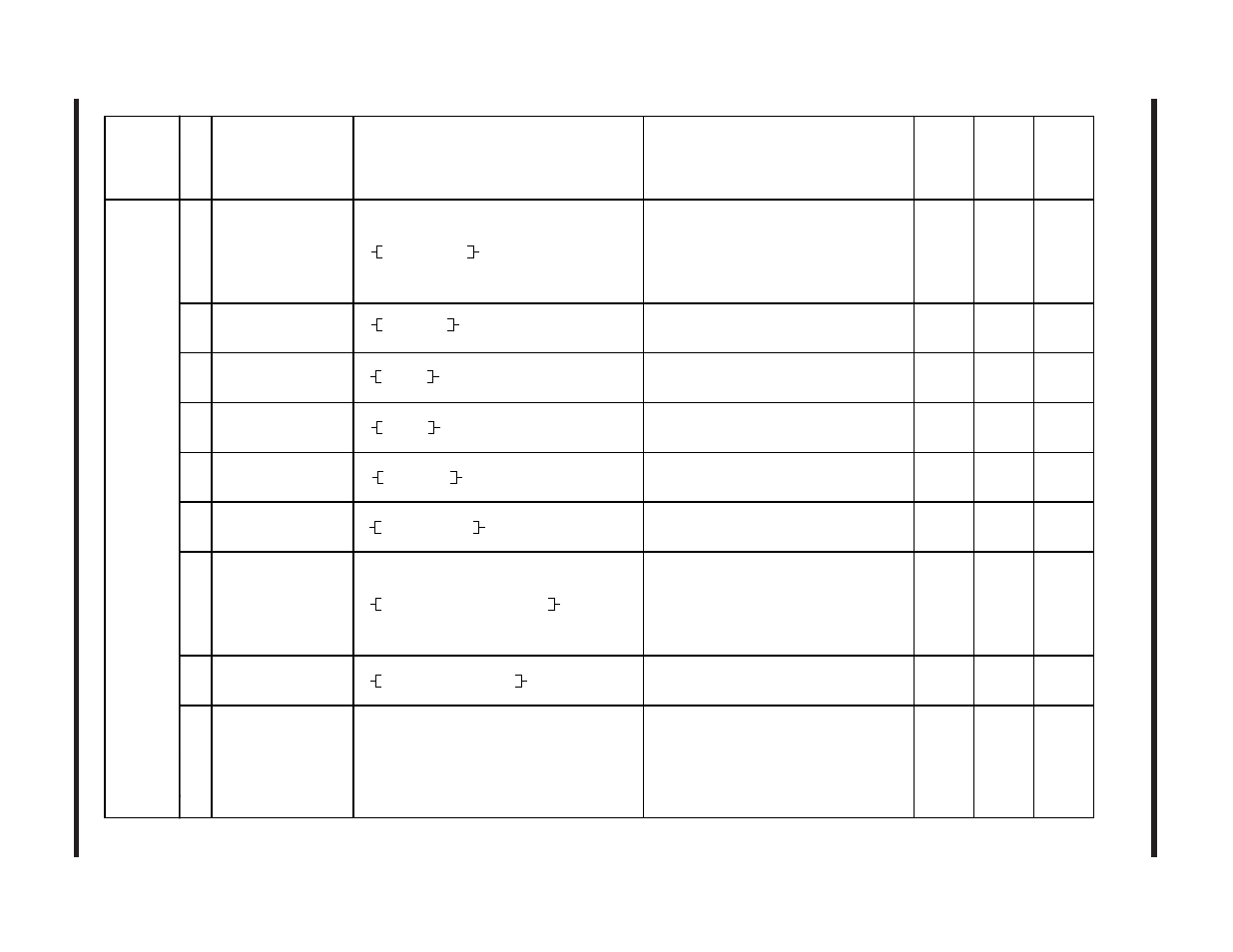

Ladder Diagram Instructions (Function Instructions)

Group

FUN

No.

Name

Representation

Summary

Number of

steps

required

Execution

time

required

(

µ

s)

Remarks

RAS

150

Diagnostic display

When input has changed from OFF to ON, the

instruction records the error code indicated by (A) in

the special register, and turns ON the corresponding

annunciator relay. The error messages (max 12

characters) recorded in the register tables headed by

(B) can be monitored on the peripheral devices.

3~4

116

151

Diagnostic display reset

Erases the error code (A) from the error code list

recorded by the diagnostic display instruction

(FUN150) and from the annunciator relay.

2~3

96

152

Status latch set

Takes the devices/registers (max 32) previously set

by the programmer and stores them in the latch area.

1

416

153

Status latch reset

Cancels the state of the status latch.

1

42

154

Set Calendar

Takes the 6 words of data headed by the register A

and sets them in the calendar LSI (date and time

setting).

2

194

155

Calendar operation

Subtracts the 6 words of date and time data headed

by (A), from the current date and time, and stores the

result in the 6 words starting with (B).

3

222

158

Drum sequencer

Compares the count value (B) with the count value

setting table ((A)+2n onwards), then decides the step

number and stores it in (B)+1.

Using the data output pattern table (A), the

instruction looks up the output pattern corresponding

to this step number and outputs it to the bit table (C).

6

✻

159

Cam sequencer

Compares the register (B) with the activation and

deactivation setting value for table (A), and carries

out ON/OFF control on the corresponding devices.

5

✻