TeeJet Matrix 840G User Manual User Manual

Page 31

www.teejet.com

48

●

98-05141 R2

49

●

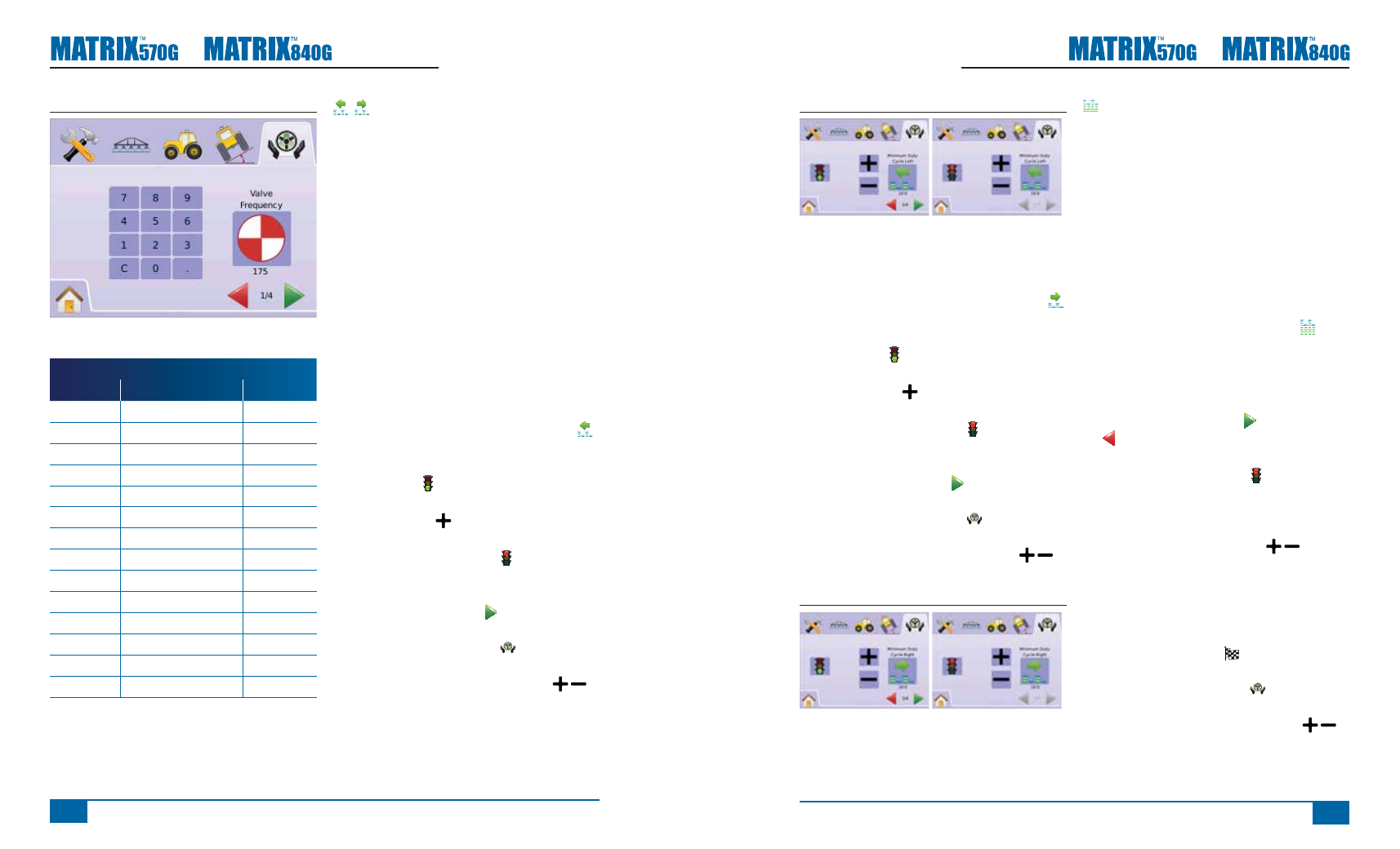

Figure 2-65: Minimum Duty Cycle Left

Cycle Right

Cycle Right sets the minimum amount of drive

required to begin steering the vehicle to the right. .

1. Press MINIMUM DUTY CYCLE RIGHT ICON .

2. While the vehicle is moving in a slow forward

straight line motion, press the GREEN

STOPLIGHT .

3. Slowly increase the duty cycle number using the

PLUS BUTTON until the vehicle begins to

turn right.

4. Press the RED STOPLIGHT to complete the

right test.

5. Press

►PAGE RIGHT ARROW to proceed to

Maximum Duty Cycle.

►FIELDPILOT SETUP TAB to return to

main FieldPilot Setup.

NOTE: Press & hold PLUS/MINUS ICONS to

quickly adjust settings.

Figure 2-66: Minimum Duty Cycle Right

Maximum Duty Cycle

Maximum Duty Cycle sets the maximum speed that

the wheels will steer from left to right / right to left

(lock to lock). Range is 25 - 100.

NOTE: If the valve frequency is below 15 Hz (non

proportional), set the value to 100. Speed

will be established during the Valve Test.

WARNING: PINCH POINT HAZARD!

To prevent serious injury or death, avoid

unsafe practice while manually operating

hydraulic steering circuits. Keep others away

and stay clear of mechanical linkages.

1. Press MAXIMUM DUTY CYCLE ICON .

2. Set Max Duty Cycle value to approximately 60

(or refer to FieldPilot manual for desired lock to

lock times).

3. Turn the wheels all the way to the left (or right).

4. Press the GREEN ARROW (or RED ARROW

). This will start a timer below the STOPLIGHT

as well as turn the vehicle to the right (or left).

5. Press the RED STOPLIGHT when the

wheels are all the way to the right (or left). The

time displayed under the STOPLIGHT is the lock

to lock time.

6. Press the PLUS/MINUS ICONS to adjust

the Max Duty Cycle value.

7. Repeat steps 3 through 6.

8. When the time from left to right / right to left (lock

to lock) begins increasing (it takes longer to turn

the tires) press

►CHECKERED FLAG to complete Valve

Setup.

►FIELDPILOT SETUP TAB to return to

main FieldPilot Setup.

NOTE: Press & hold PLUS/MINUS ICONS to

quickly adjust settings.

Figure 2-64: Valve Frequency

The following are common frequencies/valves:

TeeJet Technologies

Part #

Valve

Frequency

35-02151

FP, CC, NP

2 hz

35-02152

FP, OC, HF, NP

2 hz

35-02153

FP, OC, NP

2 hz

35-02173

FP, PC, LS, NP

2 hz

35-02172

FP, PC, PWM, LS

175 hz

35-02179

FP, PC, PWM, LS

175 hz

35-02180

FP, CC, PWM

110 hz

35-02181

FP, CC, PWM, LS

110 hz

35-02182

FP, CC, PWM

175 hz

35-02183

FP, CC, PWM 1.1 OC 110 hz

35-02184

FP, CC, PWM 7.9 OC 175 hz

35-02185

FP, CC, PWM 2.1 OC 110 hz

35-02186

FP, CC, PWM 4.0 CC 110 hz

35-02187

FP, CC, PWM 7.9 CC 175 hz

For valves manufactured by sources other than

TeeJet Technologies, refer to manufacturer’s

specifi cations for appropriate valve frequency.

Minimum Duty Cycle

Minimum Duty Cycle sets the minimum amount of

drive required to begin steering the vehicle left or

right. Range is 0.0 - 50.0.

RECOMMENDATION – Have a large area of clear

space available to perform test cycles.

NOTE: If the valve frequency is set below 15 Hz

(non proportional), set the amount of drive to

“25.0”. Cycle test is not necessary.

WARNING: PINCH POINT HAZARD!

To prevent serious injury or death, avoid

unsafe practice while manually operating

hydraulic steering circuits. Keep others away

and stay clear of mechanical linkages.

Cycle Left

Cycle Left sets the minimum amount of drive

required to begin steering the vehicle to the left. .

1. Press MINIMUM DUTY CYCLE LEFT ICON .

2. While the vehicle is moving in a slow forward

straight line motion, press the GREEN

STOPLIGHT .

3. Slowly increase the duty cycle number using the

PLUS BUTTON until the vehicle begins to

turn left.

4. Press the RED STOPLIGHT to complete the

left test.

5. Press

►PAGE RIGHT ARROW to proceed to

Minimum Duty Cycle Right.

►FIELDPILOT SETUP TAB to return to

main FieldPilot Setup.

NOTE: Press & hold PLUS/MINUS ICONS to

quickly adjust settings.