2 storage and installation checks, Reznor, Receiving, moving, and storage (cont'd) – Reznor MAPS II Unit Installation Manual User Manual

Page 6: 1 receiving and moving (cont'd)

Form I-MAPS II, Page 6

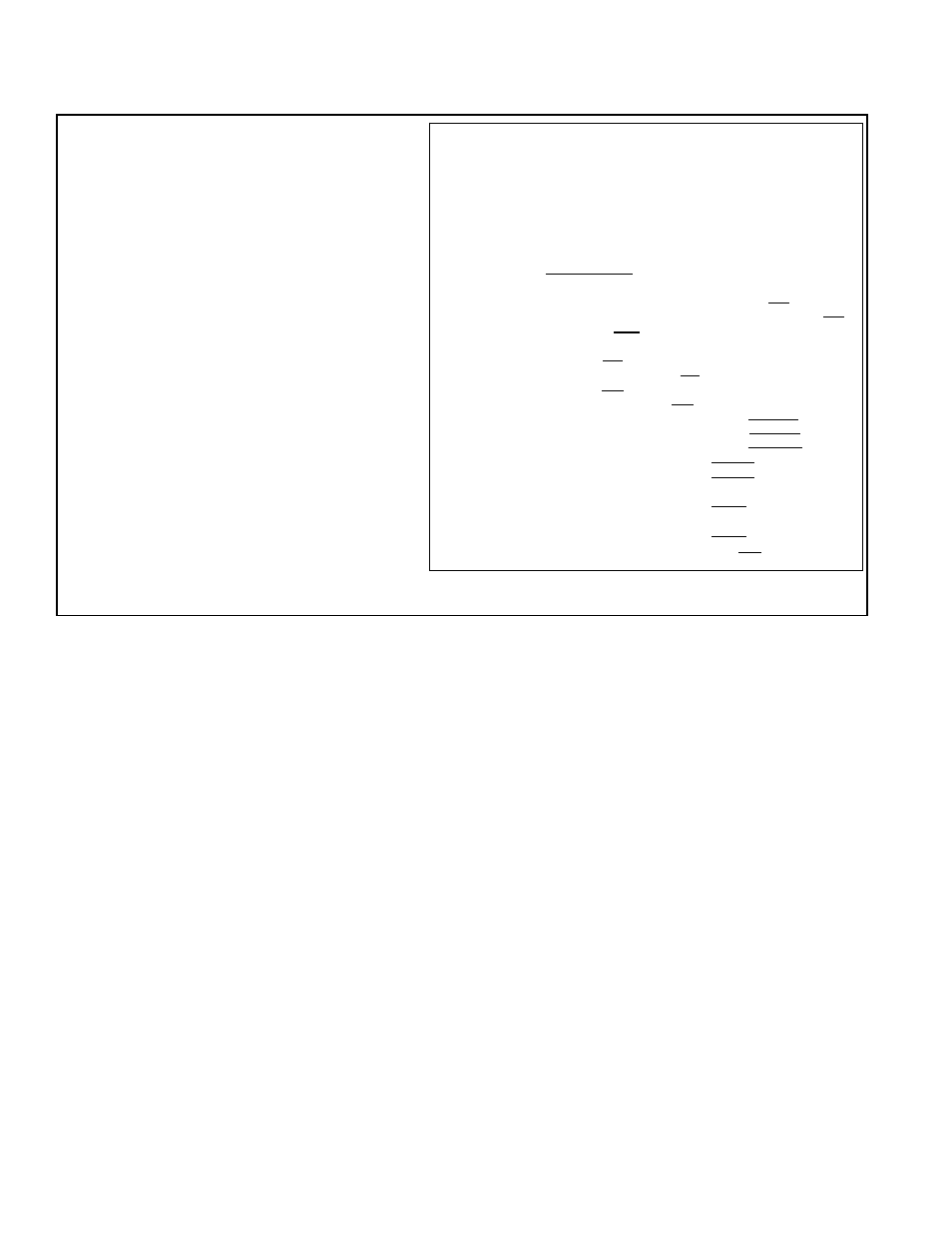

Gas Heat Section Rating Plate Key:

A = ANSI Standard Date

B = CSA Standard Date

C = Model No.

D = Amps

E = Type of Gas (natural or propane)

F = Orifice Size of Large Burner

G = Orifice Size of Small Burner

H = Normal BTUH Input (sea level)

I = Thermal Output BTUH (sea level)

J = Minimum BTUH Input (sea level)

K = Manifold Pressure

L = Minimum Gas Supply Pressure

M = Maximum Throughput

N = Minimum Throughput

P = Manufacturing Date (Month/Year)

Q = Altitude in Feet

R = Altitude in Meters

FIGURE 1B - Sample of a Gas-Fired

Heat Section Rating Plate (applies to

Models RDCA and RDDA)

3.2 Storage and

Installation

Checks

If this system is going to be stored, take precautions to prevent condensate

formation inside the electrical compartments and motors. To prevent damage

to the unit, do not store sitting on the ground.

After the system has been moved to its installation site, remove all of the ship-

ping brackets and check all of the fans for free movement. See the check

lists in Paragraph 10 before starting the unit and complete the Startup Form

(shipped in the literature envelope).

DUCT FURNACE/GÉNÉRATEUR D'AIR CHAUD À GAINE

CATEGORY III/CATÉGORIE III

FOR INDUSTRIAL/COMMERCIAL USE ONLY

POUR USAGE INDUSTRIEL/COMMERCIAL

ANSI Z83.8b - [ A ]

CGA 2.6b-M [ B ] DUCT FURNACE/GÉNÉRATEUR D'AIR CHAUD À GAINE

MODEL/MODÈLE [ C

] [ P ]

SERIAL NO./#DE SÉRIE:

[ ]

230 VOLTS 1 PH 60 HZ MAXIMUM TOTAL INPUT [ D ] AMPS

CONSOMMATION TOTALE MAX. DE [ D ] A

TYPE OF GAS/TYPE DE GAZ: [ E ]

ALTITUDE [ Q ] FEET/PIEDS, [ R ] MÈTRES

LARGE BURNER ORIFICE SIZE [ F ] DRILL HAS BEEN FACTORY ADJUSTED

GRAND BRULEUR DIMENSION DE L'ORIFICE [ F ] FORET

SMALL BURNER ORIFICE SIZE [ G ] DRILL HAS BEEN FACTORY ADJUSTED

PETIT BRULEUR DIMENSION DE L'ORIFICE [ G ] FORET

NORMAL INPUT/ENTRÉE NORMALE

[

H ] BTU/HR

THERMAL OUTPUT CAPACITY/RENDEMENT THERMIQUE [ I ] BTU/HR

MINIMUM INPUT/ENTRÉE MIN.

[ J ] BTU/HR

NORMAL MANIFOLD PRESSURE

[ K

] IN.W.C.

PRESSION NORMALE DE LA TUB

[ K

] PO/COL D'EAU

MIN. PERMISSIBLE GAS SUPPLY PRESSURE

FOR PURPOSE OF INPUT ADJUSTMENT.

[ L ] IN.W.C.

PRES. D'ALIM. MIN. ACCEPTABLE DE GAZ POUR

DES FIN DE RÉGLAGE DE L'ENTRÉE

[

L ] PO/COL D'EAU

MAXIMUM THROUGHPUT / MINIMUM THROUGHPUT [

M ] / [ N ] C.F.M.

CONSOMMATION MAXIMUM / MINIMUM [ M ] / [ N ] PI3/MN

REZNOR

MERCER, PA USA 16137

Check for shipped-separate accessories and shipped-loose parts.

All heating systems and cooling only systems with Option DU1 have a dis-

charge sensor temporarily installed in the control compartment for the conve-

nience of the installer at startup. (NOTE: Cooling only systems without Option

DU1 have a discharge air sensor installed in a permanent location.) Depending

on the application and optional controls, a sensor installed in a temporary loca-

tion will have to either be relocated to the ductwork.

The roof curb is shipped separately (See Paragraph 5.2), and in most cases, in

advance of the unit. A Model JHUP-0250 duct furnace curb section, an outside

air hood, hood for optional power exhaust, optional economizer, or optional

energy recovery module are shipped separately for field installation.

If ordered as options or components of options, other items that are shipped

separately include a remote console, a disconnect switch, a discharge temper-

ature control, a space temperature control, a space reheat override, an over-

ride thermostat, a room humidistat, a duct smoke detector, and/or a firestat.

Shipped-Separate

Accessories and

Shipped-Loose Parts

3. Receiving, Moving, and Storage (cont'd)

3.1 Receiving and Moving (cont'd)

NOTE: Same type of rating plate applies to a Model JHUP-0250 Curb Duct Furnace.