2 remote console – Reznor MAPS II Unit Installation Manual User Manual

Page 31

Form I-MAPS II, P/N 206131 (Rev 13), Page 31

Wire

Gauge

Maximum Sensor

Wire Length

(Digital Control)

AWG

Feet

Meters

14

800

244

16

500

152

18

310

94

20

200

61

22

124

38

Push the sensing element into the clip attached to the inside of the sensor holder. Turn

the metal holder so that the element will be shielded from direct airflow and will sense

the temperature in the airstream as it flows through the holes in the sensor holder.

At the location selected, mark the diamond-shaped hole required for the sensor holder.

Cut the hole no larger than required for the holder, approximately 1" x 1" (25mm x

25mm).

In the electrical box portion of the sensor holder, determine where the sensor wire

should come through the box and remove the knockout at that location.

3. Attach the sensor holder assembly. Slide the sensor holder into the opening in the

ductwork. Using four field-provided No. 6 sheetmetal screws, attach the box to the duc-

twork. Attach a field-supplied cable connector to the box, run the sensor wire out, and

attach the cover to the box.

4. Run the sensor wire to the unit. Digital control inputs are low-current, resistance-

based signals. The manufacturer recommends for optimum temperature control per-

formance that the analog and digital inputs (zone sensors, discharge air sensors, etc.)

that are connected to the FX05 or FX06 controller be routed to the unit in one of the

following manners:

• In separate field-supplied conduits, isolated from 24 VAC controls and line volt-

age power to the unit, OR

• If the digital wires are to be run in the same field-supplied conduit as the 24

VAC control wiring, the digital wiring must be completed using shielded cable

and bundled separately from 24 VAC control wiring. The shield must be drained

at the unit and taped on the opposite end.

NOTE: If wire is supplied

with the sensor, it is 22

AWG.

8.2 Remote Console

������

��

������

��

�

��������������

���

����

��

����

�������������

���� ����

����

�����

������

A selection of remote consoles is available with certain appropriate combi-

nations of controls factory mounted. All consoles include indicator lights for

blower and cooling operation and an auto/off control switch. NOTE: The auto/

off switch must be closed (Auto) for the display on the programmable control-

ler (

FIGURE 16, page 28) to read "on" (Terminals TB-48 and TB-49). Burner

indicator light, dirty filter light, and mode switches depend on option selection.

If the unit is ordered with a damper control option that includes a potentiometer,

the potentiometer may be mounted on the console.

If any of the field-mounted optional cooling/heating or reheat controls

are ordered, one may be mounted on the remote console. Console

dimensions with mounting ring are length 15-3/4" (400mm) x height

7-5/8" (194mm) x depth 2-5/8" (67mm). If recessing the console (not

using the mounting ring), subtract 7/8" (22mm) from the height and

width.

Wire controls on the remote console according to the wiring diagram.

Refer to the chart (left) for minimum control wire gauge by length.

Field Control Wiring Length/Gauge

Total Wire

Length

Distance from

Unit to Control

Minimum

Recommended

Wire Gauge

ft

M

ft

M

150 46

75

23

18

250 76

125

38

16

350 107 175

53

14

Dirty Filter Switch - If there is a dirty filter indicator light on the console, there

is a dirty filter switch in the unit. For location, see

FIGURE 20 or 21, page 33,

Item 14. After the unit is started, before continuous operation, the dirty filter

switch must be set.

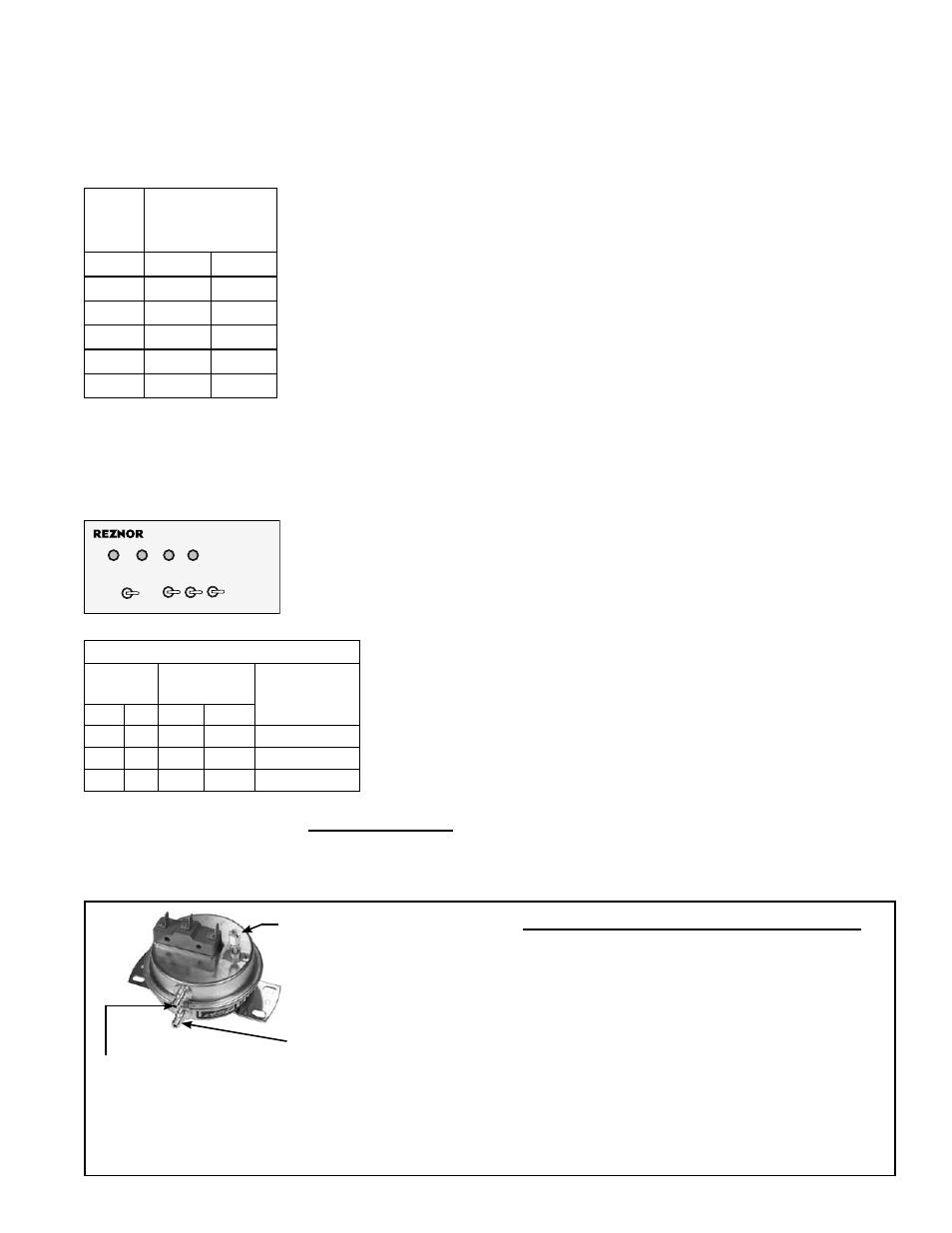

FIGURE 19 - Dirty

Filter Switch,

P/N 105507

Setscrew (on front of

switch) must be manually

adjusted after the system

is in operation.

Negative pressure

connection is toward

the "front or top" of

the switch (senses

blower side of filters)

Positive pressure

connection is toward the

"back or bottom" of the

switch (senses air inlet

side of filters)

Instructions for Setting Dirty Filter Switch -

With clean filters in place; all doors closed

(except electrical compartment); and the

blower operating, increase the pressure set-

ting by adjusting the setscrew on the switch

clockwise until the filter light is energized or the

screw is bottomed out. At that point, adjust the

setscrew three full turns counterclockwise or

until the screw is top-ended. At that setpoint,

the filter light will be activated at approximately

50% filter blockage.