3 gas heat module - models rdca and rdda (cont'd) – Reznor MAPS II Unit Installation Manual User Manual

Page 46

Form I-MAPS II, Page 46

Optional Gas

Pressure Safety

Switches

If the manifold is equipped with optional high and/or low gas pressure switches,

the switches protect against a malfunction that would cause an increase or

decrease in the regulated gas pressure.

The low gas pressure switch is an automatic reset switch factory set to activate

if the gas pressure is 50% of the minimum as stated on the unit rating plate.

The high gas pressure switch is a manually reset switch that is set to activate if

the gas pressure is 125% of the manifold pressure stated on the rating plate.

(See

FIGURES 33A

and

33B.)

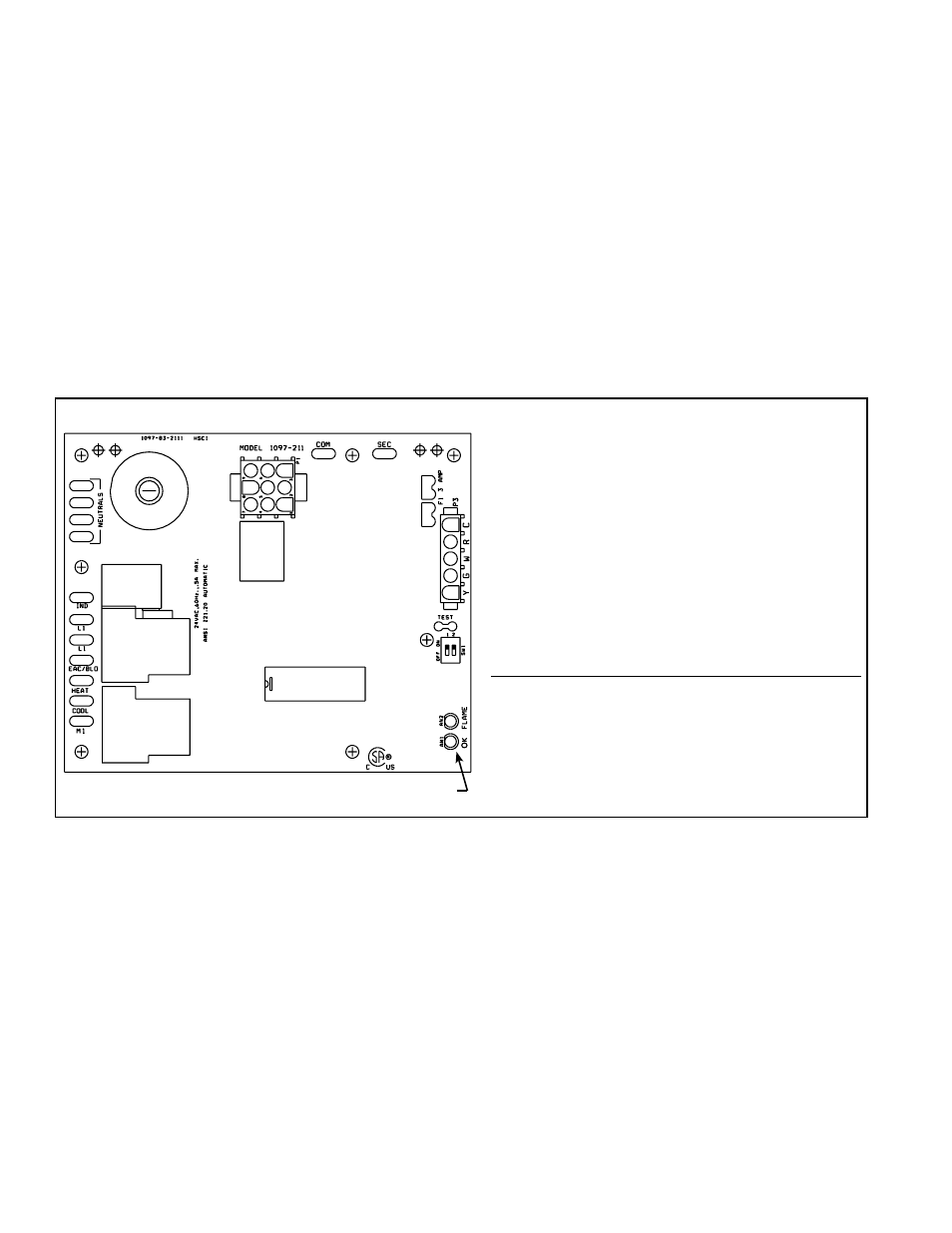

Control Status - Green LED Codes

Steady ON . Normal Operation, No call for heat

Fast Flash .. Normal Operation, Call for heat

1 Flash ....... System Lockout, Failed to detect or

sustain flame

2 Flashes ... Pressure switch did not close within

30 seconds of venter motor

3 Flashes ... High limit switch open

4 Flashes ... Pressure switch is closed before

venter motor is energized

Steady OFF Blown Fuse, No Power, or

Defective Board

Flame Status - Yellow LED Codes

Steady ON . Flame is sensed

Slow Flash . Weak flame (current below 1.0

microamps ±50%)

Fast Flash .. Undesired Flame (valve open and

no call for heat)

FIGURE 387 – DSI Integrated Control Module (circuit board)

�����

�����������

�������

����

����

����������

�����������

������

������

�

LED Lights

9.3.3 Ignition System

This furnace is equipped with a direct spark integrated control module (circuit

board). The module monitors the safety devices and controls the operation of

the venter motors and the gas valve between heat cycles.

1) Call for Heat - The heating/cooling system controller calls for heat. The igni-

tion system circuit board checks to see that the limit switch is closed and the

pressure switch is open. If the limit switch is open, the circuit board responds

as defined in the “Abnormal Heat Cycle, Limit Switch Operation”. If the pres-

sure switch is closed, the circuit board will do four flashes on the green LED

and wait indefinitely for the pressure switch to open. If the pressure switch is

open, the circuit board proceeds to prepurge.

2) Prepurge - The circuit board energizes the venter motor and waits for the

pressure switch to close. If the pressure switch does not close within 30 sec-

onds of the venter motor energizing, the circuit board will do two flashes on the

green LED. The circuit board will leave the venter motor energized indefinitely

as long as the call for heat remains and the pressure switch is open.

When the pressure switch is proven closed, the circuit board begins the pre-

purge time. If flame is present any time while in prepurge, the prepurge time

is restarted. If flame is present long enough to cause lockout, the circuit board

responds as defined in “Fault Modes, Undesired Flame”.

Normal Heat Cycle

Operating Sequence

9.3 Gas Heat Module - Models RDCA and RDDA (cont'd)

9. Optional

Equipment

including

Heat Sections

(cont'd)

9.3.2 Gas Heat Module - Mechanical (cont'd)

9.3.2.1 Gas Piping and Pressures (cont'd)