5 startup form, Startup form, Startup checklist - general checks (reference) – Reznor MAPS II Unit Installation Manual User Manual

Page 57

Form I-MAPS II, P/N 206131 (Rev 13), Page 57

Applies to:

MAPS II Model Series RCA, RDA, RDCA, RDDA, RECA, and REDA

Modular Air Processing Systems

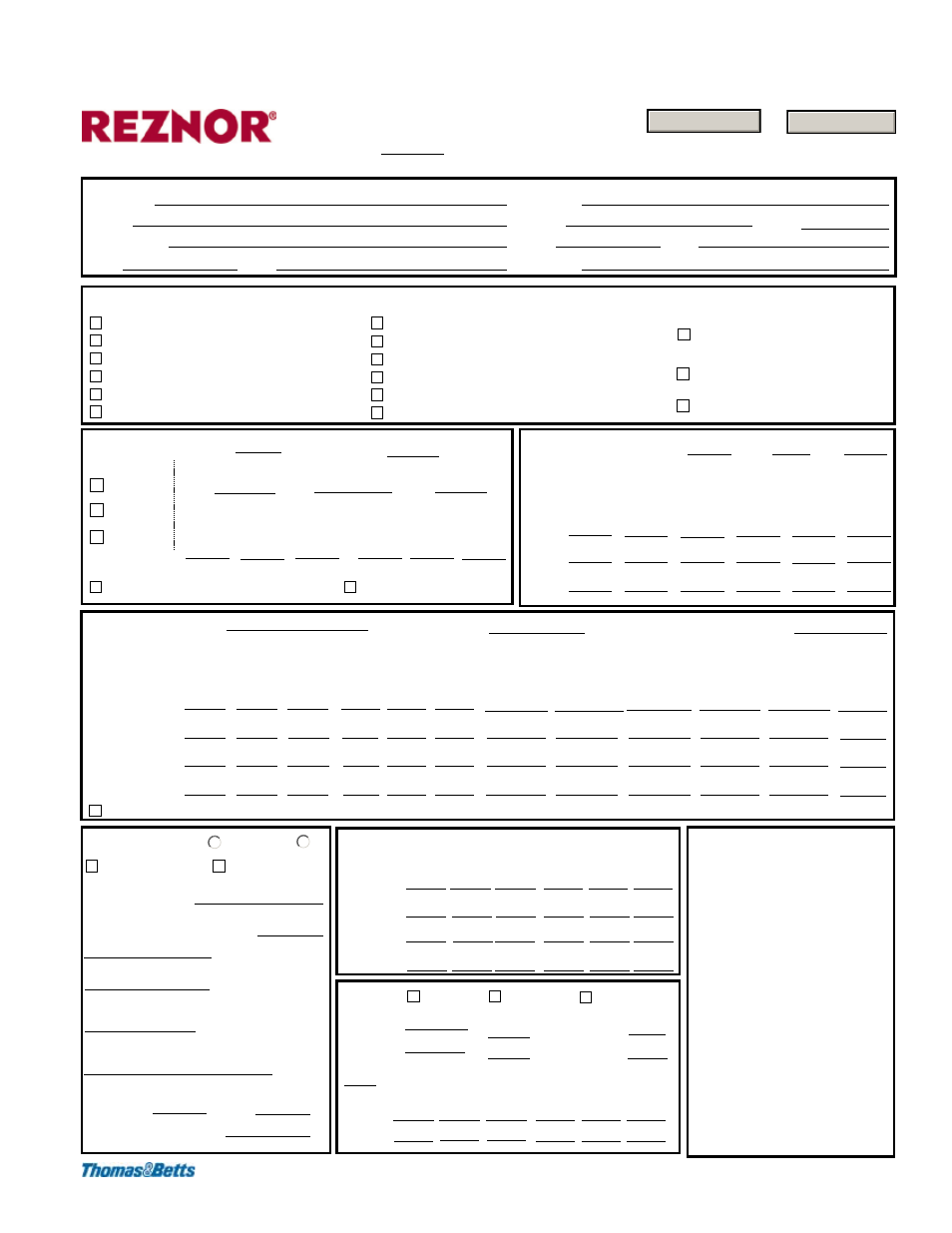

STARTUP FORM

Job Name

Contractor

Verify shipping brackets are removed.

Inspect unit for damage. (I-MAPS II, Sec. 3.1)

Inspect dampers.

Check condensate connections. (I-MAPS II, Sec. 6.2)

Verify air filters are installed. (O-MAPS II, Sec. 3)

Verify all copper tubing is isolated and does not rub.

Check for manual resets (firestat, high

gas pressure switch)

Check outside air hood and filters. (I-MAPS II, Sec. 6.3)

Check and tighten all electrical terminals.

Check clearances (I-MAPS II, Sec. 4.3)

Blower

Assembly

Alignment

Belt tension

Rotation

Motor HP

Seal electrical entrances.

Nameplate Amps

RPM

E.S.P.

L1 - L2

L2 - L3

L3 - L1

RLA-1

RLA-2

RLA-3

Startup Checklist - General Checks (Reference)

Condenser

Fans

Nameplate HP

Volts

RLA

Fan 1

Fan 2

Fan 3

L2 - L3

L3 - L1

RLA-1

RLA-2

RLA-3

Compressor

Data

Outdoor Air Conditions:

Entering Dry Bulb

Entering Wet Bulb, Dewpoint, or % RH

Circuit

Compressor A

Compressor B

Compressor C

D or Reheat DH

RLA-3

RLA-2

RLA-1

L3 - L1

L2 - L3

L1 - L2

Nameplate

RLA

Head Press

PSIG

Suct Press

PSIG

Superheat

DAT

Subcooling

Street

City, ST, Zip

Date

Contact

Model

Serial No.

Gas Heat Section

Leak test gas piping

Purge air from lines

Inlet Gas Pressure

Maximum Inlet Gas Pressure: 14" for both natural

gas & LP

Operational Inlet Gas Pressure

Minimum Inlet Gas Pressure: 5.5"w.c. for 3-stage

naturalgas (AG55); 6.0"w.c. for 6:1 modulation

natural gas (AG57);11"w.c. for 3-stage LP (AG55)

Check Manifold Pressure (Desired outlet pressure

of single stage valve from 0-2000 ft ( 0-610M) at full

fire is 3.5" w.c. for natural gas or 10" w.c. for LP.

Operational Manifold Gas Pressure:

1/3 or Single

Burner

2/3

Burner

Electric

Heat

Section

Voltage

Option

ERV

Exhaust

Assy

Alignment

Belt tension

Air balance

L1 - L2 L2 - L3 L3 - L1 RLA-1 RLA-2 RLA-3

Intake Motor HP

Nameplate Amps

Nameplate Amps

Exhaust Mtr HP

Motor

Intake

Exhaust

Comments

Natural Gas

LP

Full Burner (Sizes 450-700)

L1 - L2

Check discharge and space sensors.

Check all fans for free movement.

Check for voltage imbalance.

(I-MAPS II, Sec. 7.2)

Tighten all screws on pulleys, bearings, and

fans (I-MAPS II, Sec. 6.4; O-MAPS II, Sec 4)

Check optional dirty filter

switch. (I-MAPS II, Sec. 8.2)

Check optional hot gas bypass valve. (I-MAPS II, Sec. 7.7)

Phone

Size

Tag

Check fuses/breakers for correct

sizing (Check unit rating plate for

electrical requirements.)

CFM.

Voltage

Amperage

Amperage

Voltage

Amperage

Voltage

Voltage

Amperage

Amperage

L3 - L1

L2 - L3

L1 - L2

RLA-3

RLA-2

RLA-1

1

2

3

4

©2008 Thomas & Betts Corporation; All rights reserved; Form ST-MAPS II, P/N 257072

Print Form

Reset Form

10.5 Startup Form

(To fill out this form on line and print or to print a blank copy, go to www.RezSpec.

com.)