4 miscellaneous electrical and control options, 4 miscellaneous electrical / control options – Reznor MAPS II Unit Installation Manual User Manual

Page 33

Form I-MAPS II, P/N 206131 (Rev 13), Page 33

TUBING SECTION

• Low Refrigerant Pressure Cutouts

• High Refrigerant Pressure Cutouts

• Filter Driers

• Liquid Line Service Gauge Ports

COMPRESSOR SECTION

• Ckt A Compressor

• Ckt B Compressor

• Ckt C Compressor

• Discharge & Suction Service Ports

• Optional Hot Gas Bypass Valve(s)

HIGH VOLTAGE ELECTRICAL

COMPARTMENT

1) Blower Motor Contactor or Starter

2) Control Transformers (as required)

3) Dehumidification Compressor

Contactor (RDA,RDDA,REDA)

4) Condenser/Compressor Contactor

5) Optional Phase Loss/Phase Rever-

sal Control (optional beginning

10/05; standard prior to 10/05)

6) Optional Damper Motor

Transformer

7) Optional Over/Under Voltage

Control

8A&B) Condenser Motor Capacitors

9) Optional Convenience Outlet

(requires separate supply line)

• Outside Air Relative Humidity

Transmitter (Std RDA/

RDDA/REDA; Optional

RCA/RDCA/RECA)

• Ckt D or Dh Compressor

• Optional Damper Motor

Models RDCA & RDDA With Gas

Heat Section (FIGURE 20 only):

21) Venter Assembly

22) Single-Stage Gas Valves

23) Optional Modulating Gas Valve

24) Optional Low Gas pressure

Switch

25) Optional High Gas Pressure

Switch

Models RECA & REDA With

Electric Heat Section (FIGURE

21 only):

26) Fuse Block/Fuses

27) Contactor

28) Low Voltage Terminals

29) Manual Reset Limit

30) Auto Reset Limit

FIELD INSTALLED

• Discharge Air Sensor (supply duct)

• Optional Return Air Firestat (duct)

• Optional Discharge Air Firestat

(duct)

• Optional Smoke Detector (duct)

• Optional wall-mounted controls in

Paragraph 8.1

AUXILIARY COMPARTMENT

10) Digital Controller (FX05 or FX06)

11) Air Proving Pressure Switch

12&13) Optional Control Relays

14) Optional Dirty Filter Switch

15) Optional Time Clock or BAS Card

16) Humidity Input Converter

Models RDCA & RDDA With Gas

Heat Section (FIGURE 20 only):

17) Combustion Air Pressure Switch

18) Ignition Control

19) Optional Power Signal Converter

20) Venter Motor Capacitor (line

voltage)

BLOWER SECTION

• Blower Motor

Models RDCA & RDDA With Gas

Heat Section (FIGURE 20 only):

• Limit Control (capillary type)

COIL SECTION

• Evaporator Coils

• Thermal Expansion Valves

• Froststat (one per cooling circuit)

• Optional Subcooling Valves

(RCA/RDCA/RECA)

FILTER AND INLET AIR

SECTION

• Inlet Air, Humidity, & Override

Sensors

8.4 Miscellaneous

Electrical and

Control Options

Other electrical or control options that could have been ordered with the unit

include phase loss monitor, over or under voltage protection, exhaust fan relay,

photoelectric air duct smoke detector, an inlet or discharge firestat, or a 115V

convenience outlet. See

FIGURES 22-26 to identify each control and its option

code. Consult the system wiring diagram for option identification. For location

of unit-mounted controls, see

FIGURE 20 or 21.

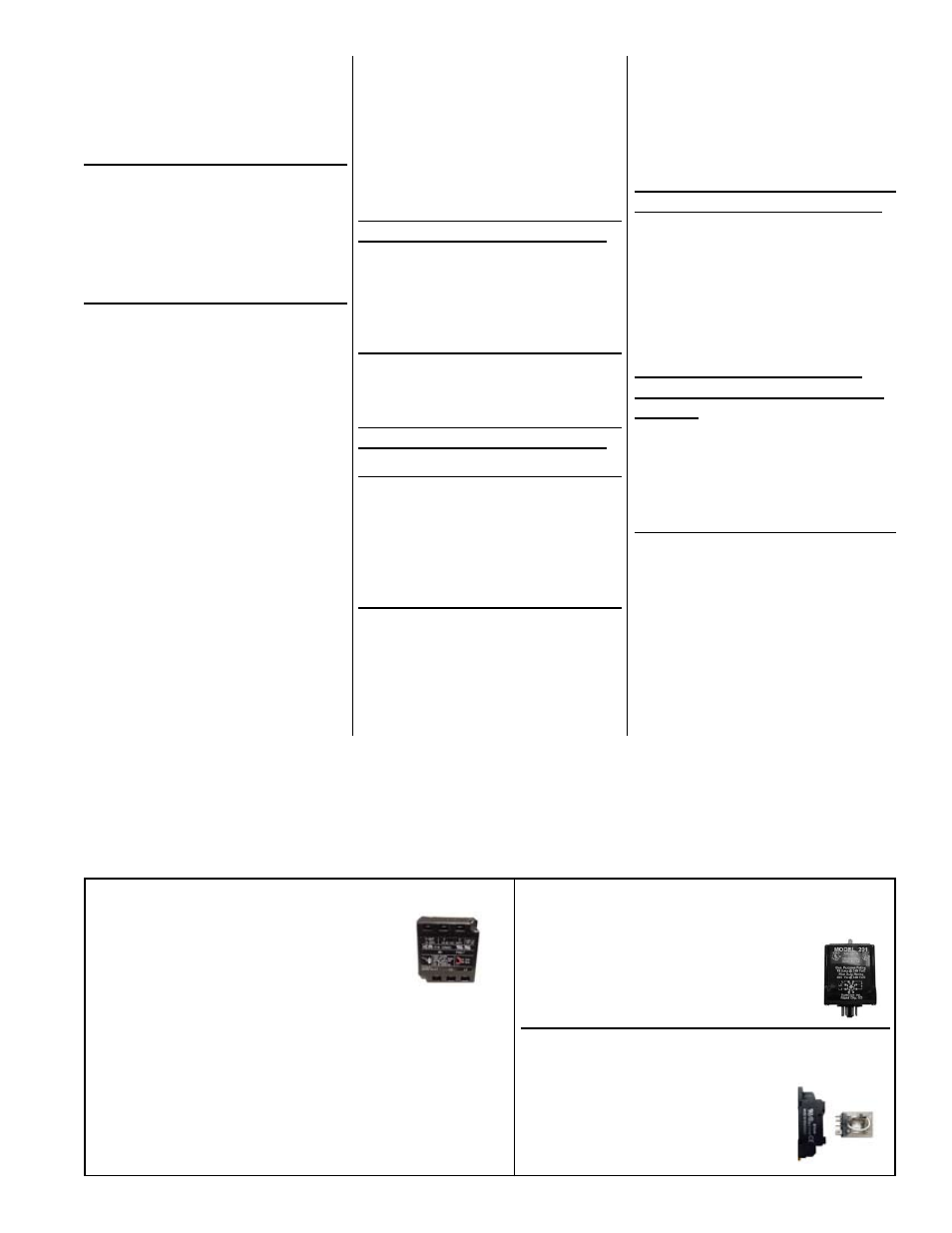

FIGURE 22B - Opt BF14, Over/Under

Voltage Protection, P/N 176826

(factory installed)

Shuts unit down on high or low volt-

age condition. Resets automatically

when power condition is corrected.

FIGURE 23 - Option BG3, Exhaust Fan

Relay, P/N 211411 (factory installed)

DPDT relay for coordination with

operation of building exhaust fan

Socket is

P/N 211415..

Auto Reset

Phase Loss

Device

With a phase loss monitor the cool-

ing compressors or heat sections

will not start or will shutdown if a

phase loss or phase reversal situa-

tion is present. This is an auto reset

device. If needed, interchange two

FIGURE 22A - Opt BF15, Phase Loss Monitor,

P/N 206105 (factory installed)

wires on the 3-phase supply connections to the line

side of the disconnect switch. DO NOT change load

side wiring. All factory installed wiring is color-coded

matched to assist in making certain the phase integrity

is in tact and to assist in troubleshooting if necessary.