Reznor MAPS II Unit Installation Manual User Manual

Page 43

Form I-MAPS II, P/N 206131 (Rev 13), Page 43

Instructions for

Checking Outlet

Pressure of Valves

(can only be done

after heater is

operating)

WARNING: Mani-

fold gas pressure

must never exceed

3.5" w.c. for natural

gas or 10" w.c. for

propane gas.

Manifold Pressure

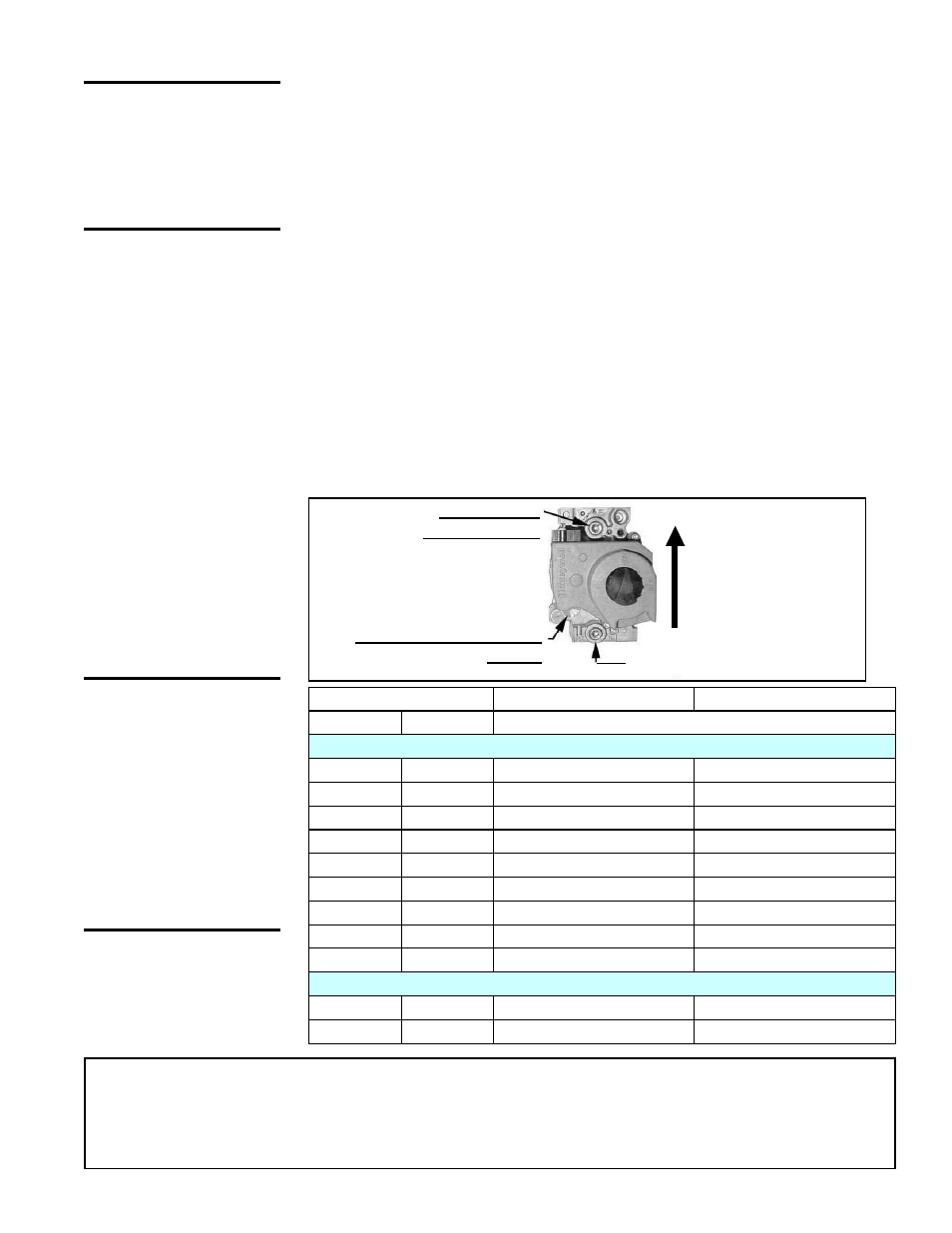

FIGURE 36 - View

of Standard Single-

Stage Valve (all units

have two) showing

Outlet Pressure Tap

and Adjustment

Locations

1/8” Output

Pressure Tap

Inlet Pressure Tap

Pressure Adjustment

Screw

Altitude

Natural Gas

Propane

Feet

Meters

Outlet Pressure of Single Stage Valves at FULL RATE

Manifold Pressure Settings by Altitude for the UNITED STATES

0-2000

0-610

3.5" w.c.

10.0" w.c.

2001-3000

611-915

3.1" w.c.

8.8" w.c.

3001-4000

916-1220

3.0" w.c.

8.5" w.c.

4001-5000

1221-1525

2.8" w.c.

8.1" w.c.

5001-6000

1526-1830

2.7" w.c.

7.7" w.c.

6001-7000

1831-2135

2.6" w.c.

7.4" w.c.

7001-8000

2136-2440

2.5" w.c.

7.1" w.c.

8001-9000

2441-2745

2.4" w.c.

6.7" w.c.

9001-10000 2746-3045

2.3" w.c.

6.7" w.c.

Manifold Pressure Settings by Altitude for CANADA

0-2000

0-610

3.5" w.c.

10.0" w.c.

2001-4500

611-1373

2.8" w.c.

8.1" w.c.

The valves are set at the factory for the appropriate outlet pressure. Check the

furnace rating plate for the manifold pressure setting.

Measuring manifold gas pressure cannot be done until the heater is in opera-

tion. It is included in the steps of the "Check-Test-Start" procedure in Para-

graph 10. The following warnings and instructions apply.

All furnaces haves two or three single-stage gas valves. Follow the instructions

to check the outlet pressure of all valves. If equipped with an optional modulat-

ing/regulating valve, unit must be operating at full rate.

Measure the Full Fire Outlet Pressure of all Single-Stage Valves - Turn the

manual valve in the gas line off. Locate the 1/8” output pressure tap on the first

single-stage gas valve (See

FIGURE 36). Connect a manometer to the 1/8"

pipe outlet pressure tap in the valve.

NOTE: A manometer (fluid-filled gauge) is

recommended rather than a spring type gauge due to the difficulty of maintain-

ing calibration of a spring type gauge.

Turn on the manual gas valve. Check the outlet pressure. (Reminder: If the

unit has optional 6:1 modulating turndown, burner must be at full fire.) Manifold

pressure for sea level operation should be 3.5" w.c. for natural gas or 10.0" w.c.

for propane gas. If the unit was ordered for high altitude operation, check the

high altitude plate or the Table below.

In most cases the outlet pressure will be correct, but in the rare instance that

adjustment is required, refer to

FIGURE 36 and follow the instructions.

Adjustment to the valve outlet pressure setting is rarely necessary. If adjustment is necessary, remove the

cap from the adjustment screw. Set pressure to correct setting by turning the regulator screw IN (clock-

wise) to increase pressure. Turn regulator screw OUT (counterclockwise) to decrease pressure. After an

adjustment is made, cycle the burner. Re-check the outlet pressure. When outlet pressure is correct for the

installation, remove the manometer and replace the cap. Check for leak at the pressure tap fitting.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result

in unregulated

manifold pressure

causing excess

overfire and heat

exchanger failure.