Reznor MAPS II Unit Installation Manual User Manual

Page 35

Form I-MAPS II, P/N 206131 (Rev 13), Page 35

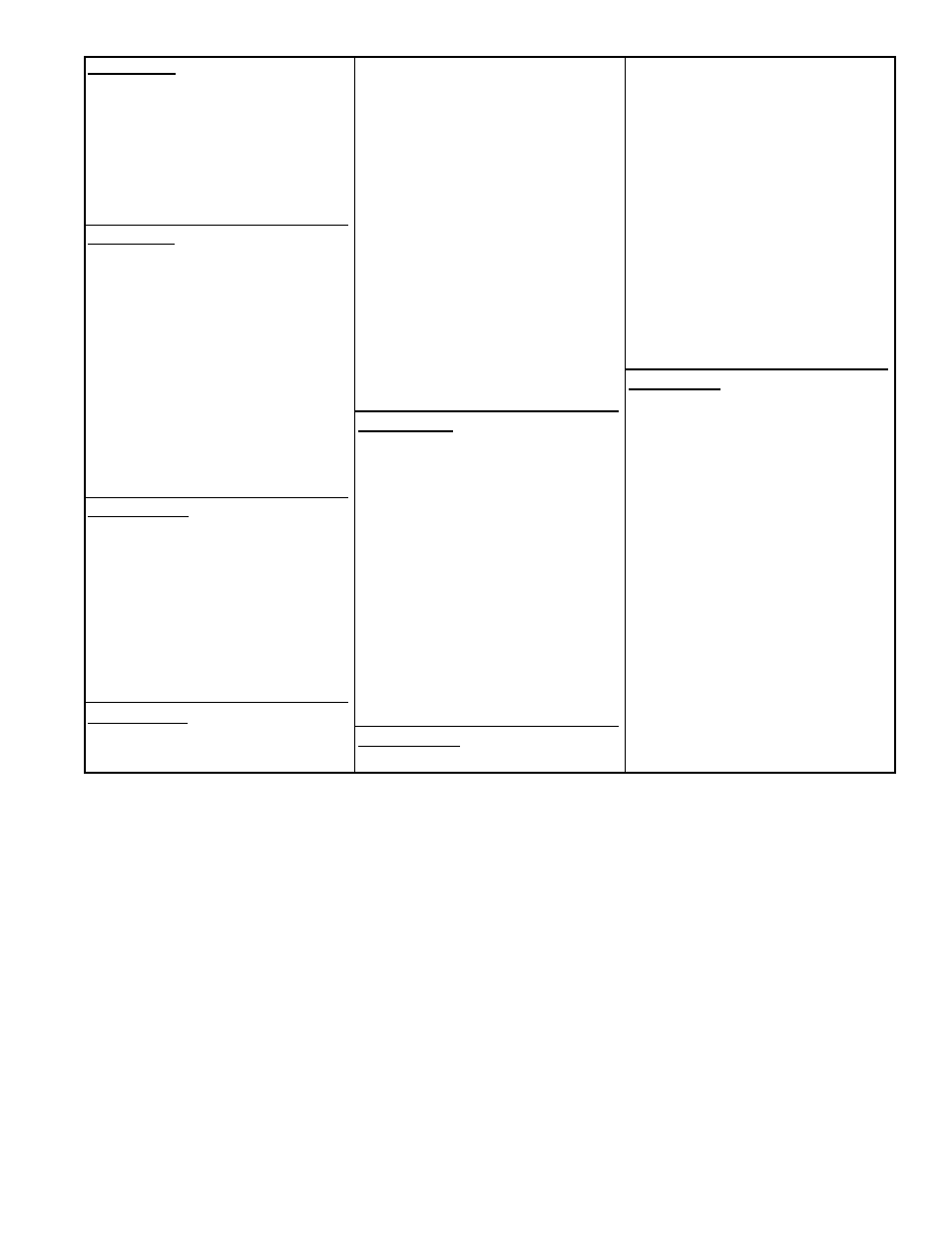

Option AR1 - Provides continuous

intake air opening. Review Build-

ing Energy Codes for approval.

(1) Outside Air Intake Hood

(Option AS16 or AS19)

Required

(2) Horizontal Outside Air Inlet

Opening

Option AR8 - Motorized outside air

damper is opened 100% during

system operation. If system is dis-

abled, outside air damper is closed

by spring return.

(1) Outside Air Intake Hood

(Option AS16 or AS19)

Required

(2) Horizontal Outside Air Intake

Opening

(4) Outside Air Dampers

(6) 2-Position Damper Motor

(open/closed)

Option AR11 - Provides manual

adjustment of return and outside

air dampers.

(1) Outside Air Intake Hood

(Option AS16) Required

(2) Horizontal Outside Air Inlet

Opening

(3) Bottom Return Air Opening

(4) Outside Air Dampers

(5) Return Air Dampers

Option AR17 - Motorized outside

air dampers are driven 100% open

and return air dampers are driven

100% closed when the system is

enabled. If system is disabled, out-

side air dampers are closed (return

air dampers opened) by spring

return. Field-installed time clocks

may provide for occupied and

unoccupied control sequences.

(1) Outside Air Intake Hood

(Option AS16) Required

(2) Horizontal Outside Air Inlet

Opening

(3) Bottom Return Air Opening

(4) Outside Air Dampers

(5) Return Air Dampers

(6) 2-Position Damper Motor

(either 100% outside air or

100% return air)

Option AR18 - Motorized outside air

dampers and return air dampers.

Damper positions are controlled

by a potentiometer that is installed

in the space.

(1) Outside Air Intake Hood

(Option AS16) Required

(2) Horizontal Outside Air Inlet

Opening

(3) Bottom Return Air Opening

(4) Outside Air Dampers

(5) Return Air Dampers

(6) Modulating Damper Motor

(7) Remote Potentiometer

(shipped separately)

Option AR23 - Modulates return

and outside air damper positions

to maintain zone pressure (modu-

lates from zero to 100%) by

regulating return and outside air

quantities (constant volume).

(1) Outside Air Intake Hood

(Option AS16) Required

(2) Horizontal Outside Air Inlet

Opening

(3) Bottom Return Air Opening

(4) Outside Air Dampers

(5) Return Air Dampers

(6) Modulating Damper Motor

(7) Remote Pressure Null Switch

(0-100% outside air) (shipped

separately)

Option AR27 - Modulates return

and outside air damper positions

to maintain zone pressure (modu-

lates from zero to 100%) by

regulating return and outside air

quantities (constant volume airflow

with minimum outside air damper

position).

(1) Outside Air Intake Hood

(Option AS16) Required

(2) Horizontal Outside Air Inlet

Opening

(3) Bottom Return Air Opening

(4) Outside Air Dampers

(5) Return Air Dampers

(6) Modulating Damper Motor

(7) Remote Pressure Null Switch

(minimum outside air damper

position) (shipped separately)

Damper Linkage

Damper linkage provides limited air balance of return and outside air quanti-

ties. Return duct and outside air hood pressure drop differentials may require

field-installed balancing devices.

NOTES: Damper linkage may not provide adequate air balance of return and

outside air quantities. Compare return duct and outside air inlet hood pressure

drops to determine balancing requirements. Damper operation is not integrated

with the standard system controller. If equipped with Option BNC1 and a time

clock, the controller will close the dampers.

Pressure Null Switch

in Damper Options

AR23 and AR27

The pressure null switch used in Option AR23 and AR27 is a Dwyer #1640-0

with a range of .01-.20" w.c. It is shipped separately for field installation. Refer

to the following paragraphs and the manufacturer's installation instructions

included with the switch.

Description and Application - The pressure null switch is a diaphragm operated

differential pressure switch used in makeup air applications to control build-

ing pressure. It maintains a selected positive or negative pressure setpoint by

changing the amount of outside air being introduced to the building through

the modulating outside air dampers. As more pressure is required in the build-