Controls (cont'd), 1 digital control systems (cont'd) – Reznor MAPS II Unit Installation Manual User Manual

Page 30

Form I-MAPS II, Page 30

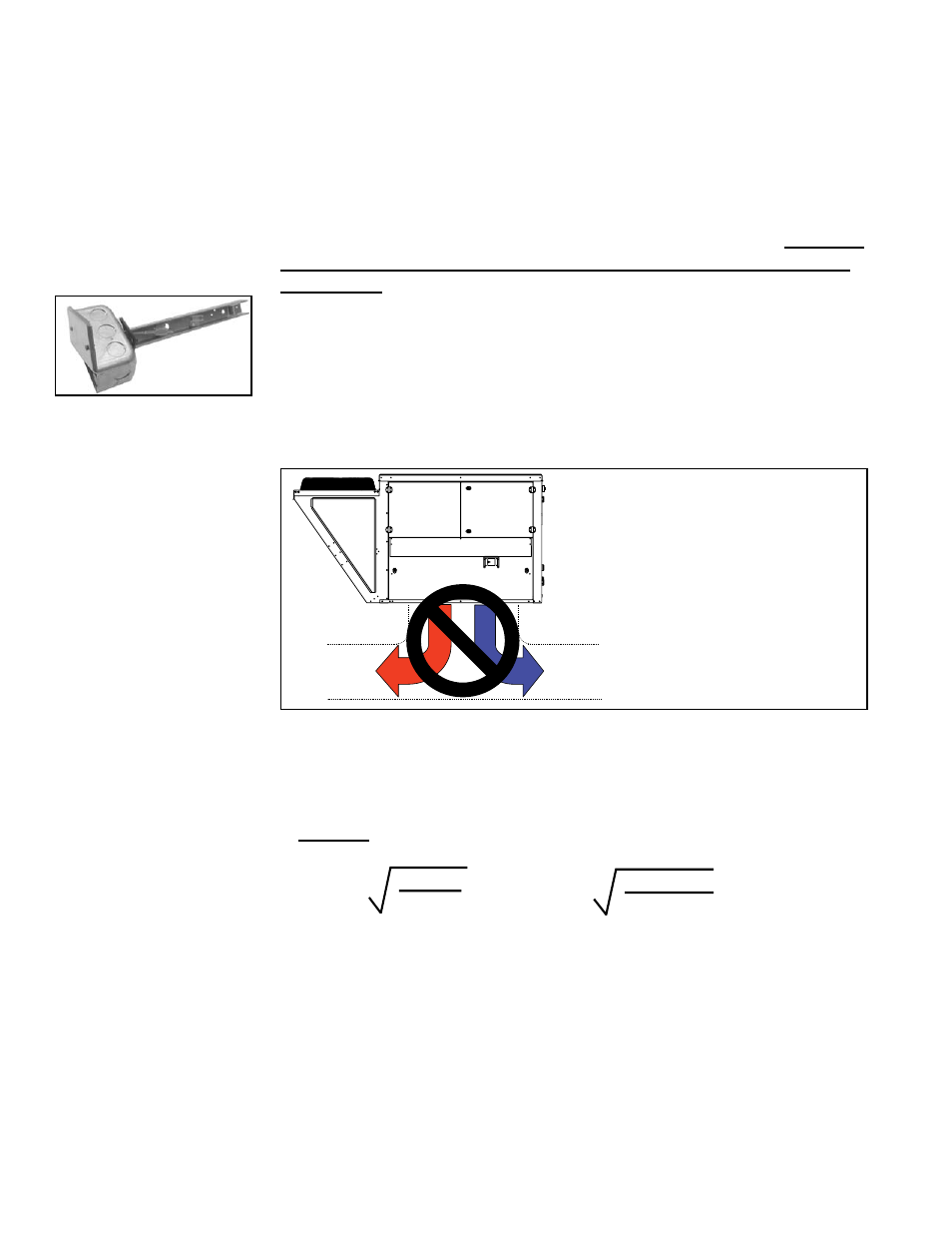

FIGURE 17 - Dis-

charge Air Sensor

Assembly in heating

systems (RDCA/

RDDA/RECA/REDA)

or cooling only sys-

tems with Option DU1

8. Controls (cont'd)

8.1 Digital Control

Systems (cont'd)

If the unit is installed in a system with

immediate “T” configuration leaving

the discharge, the 1/3 – 2/3 burner

design may allow stratification of the air.

The result is hot air only moving down

one segment of the duct while cool air

moves down the other segment. Avoid

this application. If this application is not

avoidable, provide air mixing devices

or the necessary duct length before the

“T” for mixing of the discharge air.

Hot

Air

Cool

Air

Gas Heat Section

FIGURE 18 - On

units with a gas heat

section, avoid an

immediate “T” in the

discharge duct.

Discharge Temperature Sensor (cont'd)

RCA and RDA with Option DU1, the sensor is temporarily installed for heater

startup but must be relocated to the ductwork.

When installed in the ductwork the sensor must be housed in a mixing tube

which is attached to a 2x4 electrical box. The assembled parts (See

FIGURE

17) are shipped in the control compartment. Read the instructions below and

follow carefully to relocate the discharge temperature sensor.

Discharge Temperature Sensor Relocation Instructions - Apply to

all Models RDCA/RDDA/RECA/REDA and Models RCA/RDA with

Option DU1

Placement of the discharge air sensor in the ductwork is critical to the correct

operation of a MAPS system in both the cooling and heating modes. Due to the

split burner and dual heat exchanger features of the MAPS gas heat section, it

is extremely important in the heating mode when equipped with an optional gas

heat section. The gas heat section of the MAPS unit is designed to conserve

fuel by only firing that portion of the burner or one of the dual heat exchangers

as required to supply the demand for heat. Improperly locating the sensor can

result in poor control of discharge temperature; see

FIGURE 18.

1. Determine the appropriate distance from the unit. Be sure there is sufficient dis-

tance from the outlet to have a good mixture of discharge air temperature. According to

the latest edition of AMCA Standard 201, in straight ducts, the air is typically well mixed

a minimum of five equivalent duct diameters from the discharge of the unit with equiva-

lent duct diameter defined as equal to the square root of 4AB/3.14. "A" and "B" are the

duct cross-sectional dimensions.

Example: Supply ductwork cross-sectional dimension is

24" x 12" (610mm x 305mm).

5 x

4 x 12 x 24

3.14

= 96"

5 x

4 x 305 x 610

3.14

= 2435mm

Locate the sensor a minimum of 96" (2435mm) from the

outlet of the unit.

NOTE: If the length of the discharge duct is less than 8 ft (2.4M), a mixing

vane is recommended for mixing the discharge air.

Do not mount the sensor in the ductwork after a split in the supply as that

will cause loss of control in the duct that does not house the sensor.

2. Determine the location and orientation of the sensor holder assembly. The posi-

tion of the sensor holder in the duct is also important. In horizontal ductwork, locate

the sensor assembly in the top, middle of the duct with the sensor holder extending

vertically down into the center of the airstream. In vertical ductwork, locate the sensor

assembly in the middle of the side of the duct that corresponds with the top middle of

the discharge outlet. The sensor holder will extend horizontally into the center of the

airstream.