Controls, 1 digital control systems, Electrical and wiring (cont'd) – Reznor MAPS II Unit Installation Manual User Manual

Page 28

Form I-MAPS II, Page 28

Compressor Protection

A low pressure cutoff (LPCO) switch is used for protection against compressor

damage due to a loss of system charge. This protection prevents short cycling

on the internal overload (IOL) which can pump the oil out of the compressor.

All compressors located in positions A, B, and C and the compressor in posi-

tion D on Sizes 139 and 164 have manual reset high pressure cutouts.

The hot gas bypass option provides expanded

compressor modulation at low outside air temper-

atures. It is factory set; however, the factory adjust-

ment should be checked at startup. To check the

valve operation and/or make field adjustments, it

is necessary to simulate a light load condition.

Check Bypass Valve Setting - Connect a pressure

gauge to the suction line and block the entering

air to the evaporator coil. Suction pressure will

drop, and the hot gas bypass valve should begin

to open at approximately 75 psig. The valve has a range of 6 psig and will be

fully open at 69 psig. When the valve begins to open, it will be hot to the touch.

To adjust the pressure, remove the cap and turn the adjusting stem clockwise

to increase the setting pressure and counterclockwise to decrease the setting

pressure. Make adjustments in small increments. Allow five minutes between

adjustments for the system to stabilize. When finished, replace the cap on the

adjustment stem and remove the pressure gauge.

8.1 Digital Control Systems

All systems have a unit-mounted, factory-wired, 24-volt DDC controller that is

specifically designed to control cooling (3 stages) and heating based on dis-

charge air temperature, outdoor air temperature, dewpoint, and enthalpy.

The integrated display will show the current discharge air temperature, outdoor

air temperature, dewpoint, and enthalpy; which outputs are enabled; and the

mode of operation. The controller allows the user to change setpoints, change

prop bands, and adjust the time clock (Option BHB1 with Option D12; standard

with Option D12A). For instructions on changing or adjusting the controller, see

the forms supplied in the literature envelope.

The digital controller monitors or provides the following: air proving switch, low

limit protection, anti-cycle protection, minimum on/off times, gas valve modu-

lation, and electric heat staging. Controllers may be equipped with optional

cards for use with Johnson N2 (Option BHB2) or LON (Option BHB3) Building

Automation System.

8. Controls

Both control options provide the functions listed below.

• Discharge air reset with heating/cooling setpoints

• Zone heating/cooling setpoints

• Reheat override options (disable reheat on call for cooling)

• Cooling lockouts (enthalpy)

• Discharge air reset based on outdoor dry bulb (linear reset)

FIGURE 16 - Programmable

Controllers

Summary of Control Features

available on all MAPS II Models

Reference NOTES:

For unit-mounted control

location, refer to

FIGURE

20 or 21 on pages 32-33.

7. Electrical and

Wiring (cont'd)

7.7 Compressors

(cont'd)

CAUTION: An

operating bypass

valve is very hot to

the touch.

FX05 Controller

in Option D12

FX06 Controller

in Option D12A

In addition, Option D12A control system provides.

• Real time clock function built in with 8 event, 7-day

schedule

• 9 menu selections for setpoint adjustments and unit status

• Optional remote display and remote space temperature

setpoint adjustment

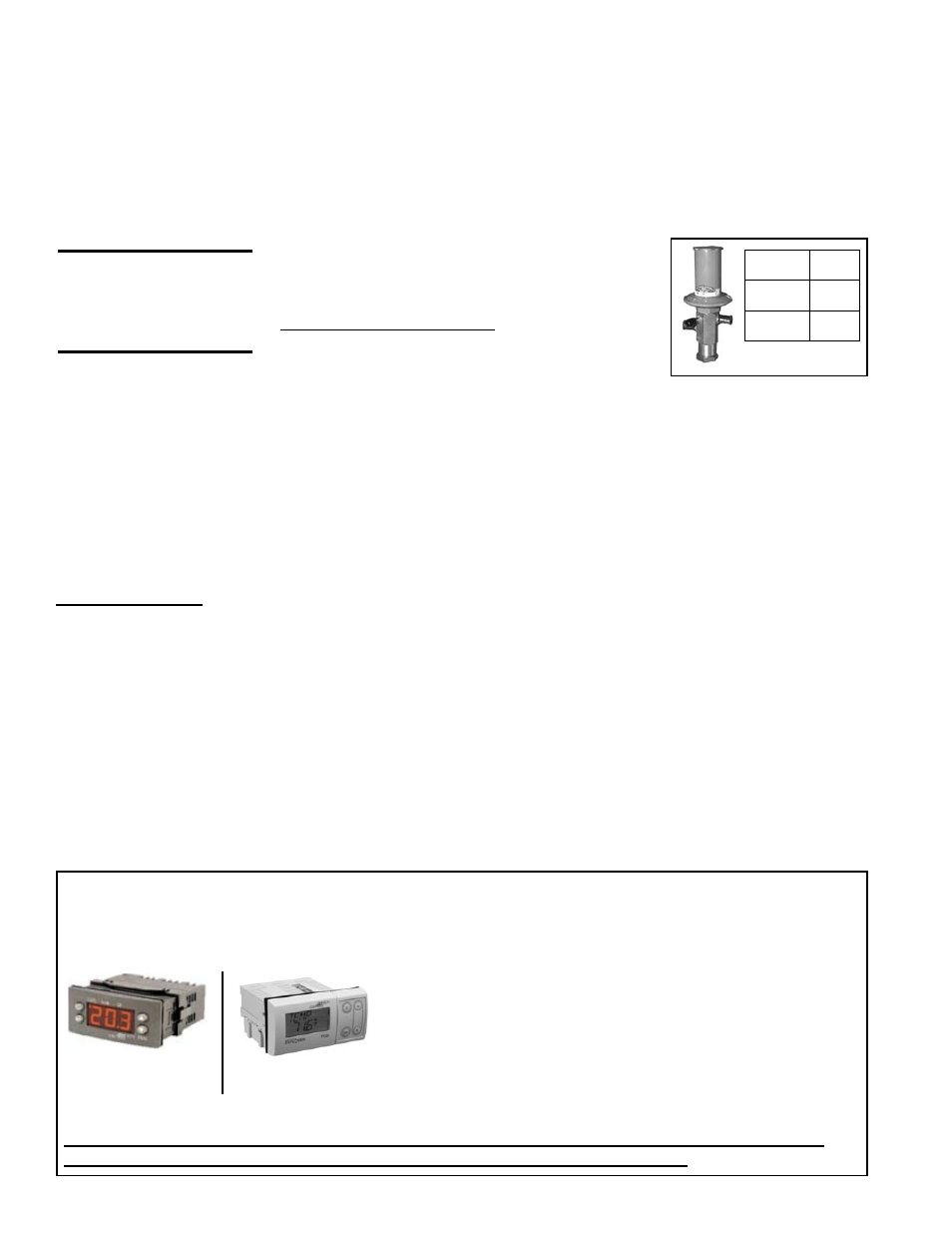

Optional Hot Gas

Bypass

FIGURE 15 - Optional

Hot Gas Bypass Valve

Adjustment

Range

0-80 PSI

Factory

Setting

75 PSI

PSI per

Turn

7.5

REFERENCE: For controller instructions, see either Form CP-MAPS D12 w/FX05 or CP-MAPS

D12A w/FX06 in the literature envelope or download from www.RezSpec.com.