3 gas heat module - models rdca and rdda (cont'd) – Reznor MAPS II Unit Installation Manual User Manual

Page 44

Form I-MAPS II, Page 44

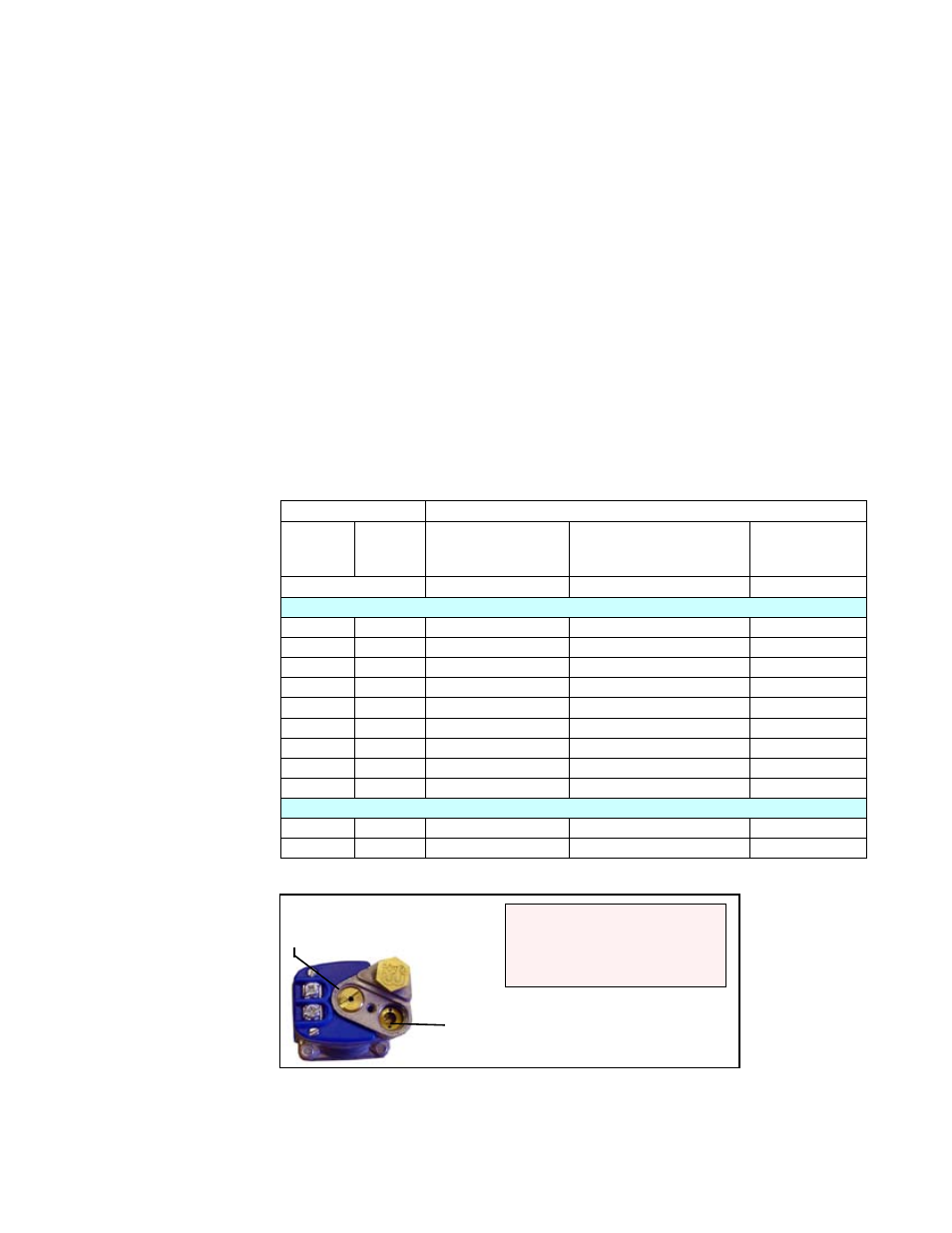

FIGURE 37 - Top

View of Electronic

Modulating/

Regulating Valve in

Option AG57, 6:1

modulating turndown

High Fire

Adjustment Screw

Low Fire Adjustment Screw

DO NOT ADJUST pressure

at the modulating valve;

contact the factory service

department.

Altitude

Natural Gas

Feet

Meters

Minimum "Fire" OUTLET

Gas Pressure for 2/3

Burner Section *

Full Rate INLET Gas Pressure at

Single-Stage Valves with both

Burner Sections Operating

Full Rate OUTLET

Gas Pressure

Tolerance

(-.1 to +.2 " w.c.)

(-.15 to +.15 " w.c.)

(-.15 to +.15 " w.c.)

UNITED STATES

0-2000

0-610

1.20" w.c.

4.5" w.c.

3.5" w.c.

2001-3000

611-915

1.05" w.c.

4.1" w.c.

3.1" w.c.

3001-4000 916-1220

1.00" w.c.

4.0" w.c.

3.0" w.c.

4001-5000 1221-1525

.95" w.c.

3.8" w.c.

2.8" w.c.

5001-6000 1526-1830

.90" w.c.

3.7" w.c.

2.7" w.c.

6001-7000 1831-2135

.86" w.c.

3.6" w.c.

2.6" w.c.

7001-8000 2136-2440

.84" w.c.

3.5" w.c.

2.5" w.c.

8001-9000 2441-2745

.80" w.c.

4.4" w.c.

2.4" w.c.

9001-10000 2746-3045

.78" w.c.

3.3" w.c.

2.3" w.c.

CANADA

0-2000

0-610

1.20" w.c.

4.5" w.c.

3.5" w.c.

2001-4500 611-1373

2.80" w.c.

3.8" w.c.

2.8" w.c.

*The 1/3 burner outlet pressure will be slightly higher; it does not need to be set.

The input and/or the capacity of the gas heat section changes with altitude.

The tables below list inputs and capacities at altitudes from sea level to 10,000

ft (3045M).

High Altitude

Capacity Changes

9.3.2 Gas Heat Module - Mechanical (cont'd)

9.3.2.1 Gas Piping and Pressures (cont'd)

9.3 Gas Heat Module - Models RDCA and RDDA (cont'd)

9. Optional

Equipment

including

Heat Sections

(cont'd)

Turn the manual valve off. Connect the manometer to the second valve and

repeat to check the outlet pressure of the other single-stage gas valves. High-

fire outlet pressure should be the same for each valve.

If equipped with Option AG57, the furnace has a modulating valve to provide

6:1 turndown. To measure the minimum fire outlet pressure, check the outlet

pressure of the single-stage valve at the 2/3 burner (See

FIGURE 33B or

35B). Connect the manometer at the same pressure tap as when measuring

high fire outlet pressure. Disconnect one of the lead wires to the modulating

valve. With the unit at full fire, measure the outlet gas pressure at the single-

stage valve. Gas pressure should be as listed for "Full Rate Inlet Pressure" in

the table below. (Modulating valve is a reverse acting valve; 0-6 is high fire and

15-24 is low fire.) If pressure is not correct, contact the factory. This setting is

not field adjustable. After checking pressure, be sure to reconnect the wire to

the modulating valve.

For reference purposes only, pressures by altitude are shown in the table below.

CONTACT THE FACTORY SERVICE DEPT IF PRESSURE IS INCORRECT.

DO NOT ADJUST.