Receiving, moving, and storage, 1 receiving and moving, Reznor – Reznor MAPS II Unit Installation Manual User Manual

Page 5: Rca or rda, Suitable for outdoor use, Rating plate

Form I-MAPS II, P/N 206131 (Rev 13), Page 5

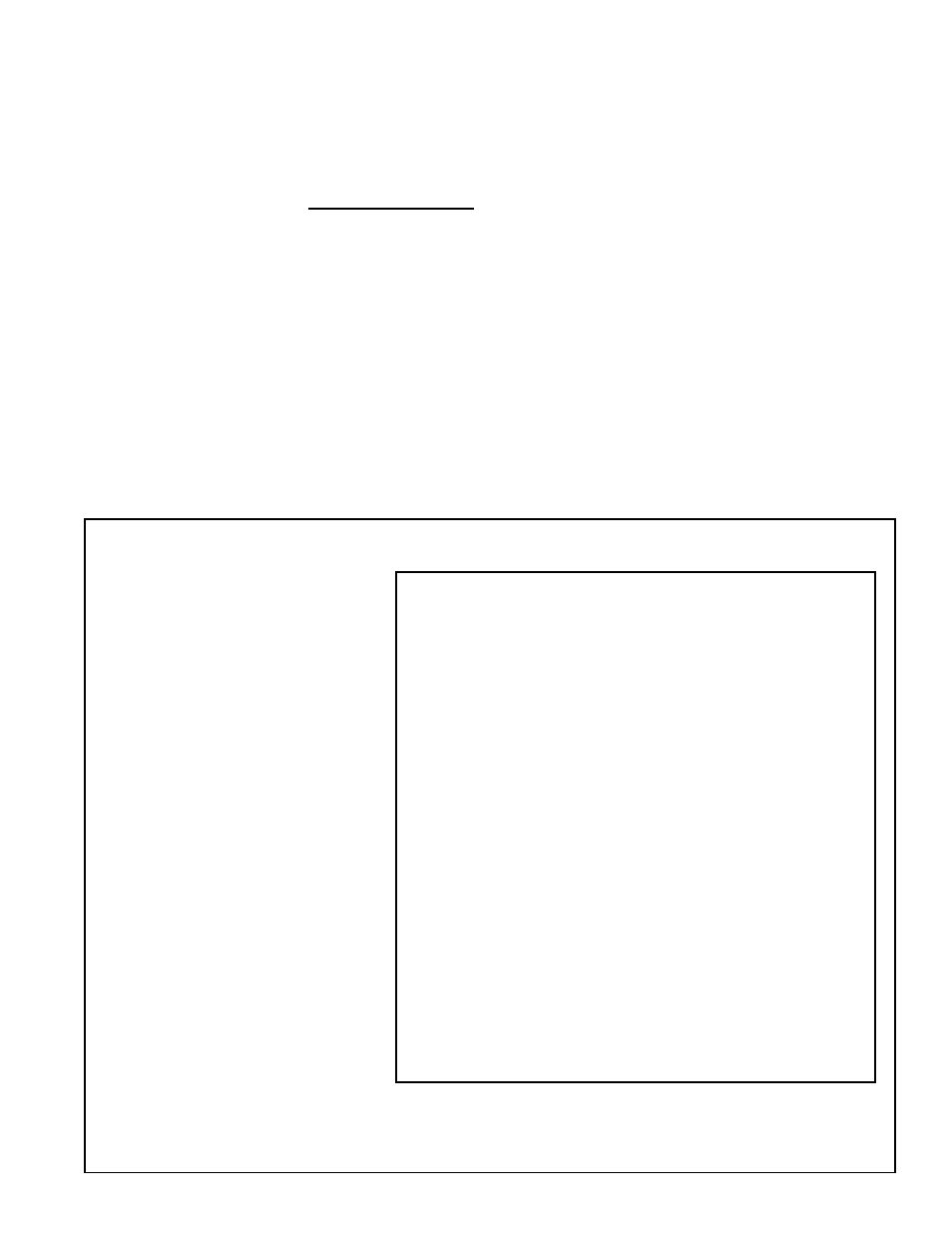

FIGURE 1A - Sample of System Rating Plate (applies to all models)

System Rating Plate Key:

A = Model

B = Manufacturing Date (Month/Year)

C = Blower Motor HP

D = Volts/Phase/Hertz

E = Full Load Amps of Blower Motor

F = Minimum Circuit Ampacity

G = Maximum Fuse Size

H = Quantity - Compressor A

I = Rated Load Amps of Compressor A

J = Locked Rotor Amps of Compressor A

K = Quantity - Compressor B

L = Rated Load Amps of Compressor B

M = Locked Rotor Amps of Compressor B

N = Quantity - Compressor C

O = Rated Load Amps of Compressor C

P = Locked Rotor Amps of Compressor C

Q = Quantity - Compressor D

R = Rated Load Amps of Compressor D

S = Locked Rotor Amps of Compressor D

T = Quantity Condenser Fan Motors

U = Rated Load Amps of Condenser(s)

V = Refrigerant Charge (lbs) - Circuit A

W = Refrigerant Charge (lbs) - Circuit B

X = Refrigerant Charge (lbs) - Circuit C

Y = Refrigerant Charge (lbs) - Circuit D

Z = Condenser Fan Motor HP

AA = Test Pressure High (psig)

BB = Test Pressure Low (psig)

CC = SCFM Airflow

DD = External Static Pressure (" w.c.)

EE = Drive (Option AM)

FF = Wiring Diagram No.

RCA or RDA

MADE IN USA

FOR INDUSTRIAL/COMMERCIAL USE ONLY

SUITABLE FOR OUTDOOR USE

MODEL [ A ]

[ B ]

SERIAL NO. [

]

[D] VOLTS +/- 10% [D] PHASE [D] HZ

MINIMUM CIRCUIT AMPACITY(MCA)

[ F ] AMPS

MAXIMUM FUSE SIZE/*CKT BREAKER

[ G ] AMPS

QTY

FLA(EA)

HP(EA)

SUPPLY AIR BLOWER MOTOR

1

[ E ]

[ C ]

CONDENSER FAN MOTOR (S)

[ T ]

[ U ]

[ Z ]

QTY

RLA (EA)

LRA (EA)

COMPRESSOR(S) A

[ H ]

[ I ]

[ J ]

COMPRESSOR(S) B

[ K ]

[ L ]

[ M ]

COMPRESSOR(S) C

[ N ]

[ O ]

[ P ]

COMPRESSOR(S) D

[ Q ]

[ R ]

[ S ]

CIRCUITS

A

B

C

D

REFRIGERANT - [ ] CHARGE - LBS

[ V ]

[ W ]

[ X ]

[ Y ]

TEST PRESSURES

HIGH [AA] PSIG LOW [BB] PSIG

EQUIPPED FOR OPERATION AT AN AIR FLOW OF [

CC ] SCFM

AGAINST A STATIC PRESSURE OF [ DD ] INCHES WATER COLUMN.

DRIVE RPM [ EE ]

WIRE DIAGRAM [ FF ]

REFER TO RATING PLATE IN THE FURNACE SECTION (WHEN USED)

FOR ADDITIONAL INFORMATION.

*HACR TYPE REQUIRED PER NEC

ELECTRICAL

REZNOR

MERCER, PA., U.S.A. 16137

Check the entire unit for damage paying particular attention to the structural

integrity of both the points of attachment of the lifting lugs and the condenser

fan section.

•

Lifting Lugs - Inspect the points of attachment of the lifting lugs.

•

Condenser Fan Section - On the side of the system, check the condenser

fan guards and the fan blades.

IMPORTANT NOTE: Sizes 176, 226, 230, 280, 292, 346, 374, 428, and

446 have a "C" Size Cabinet and MUST be loaded and unloaded

using all six lifting lugs with a spreader bar. DO NOT attempt to

move a "C" size cabinet system with a fork lift.

On the inside of the door of the high voltage electrical compartment, locate the

system rating plate (See

FIGURE 1A, below, and FIGURE 2A or 2B, page 7 or

8). Check the specifications and the electrical characteristics and verify com-

patibility with the electric supply at the installation site. Check fuses/breakers

for correct sizing.

If installing a Model RDCA, RDDA, RECA, or REDA, check the rating plate on

the inside cover of the heat section. Be sure that the rating plate information

is compatible with the electric and/or gas supply at the installation site. (See

FIGURE 1B for a sample of a gas-fired heat section rating plate.)

Rating Plate