EVCO EVF818P9 User Manual

Page 43

EVCO S.p.A.

EVF818 | Installer manual ver. 1.0 | Code 144F818E104

page 43 of 76

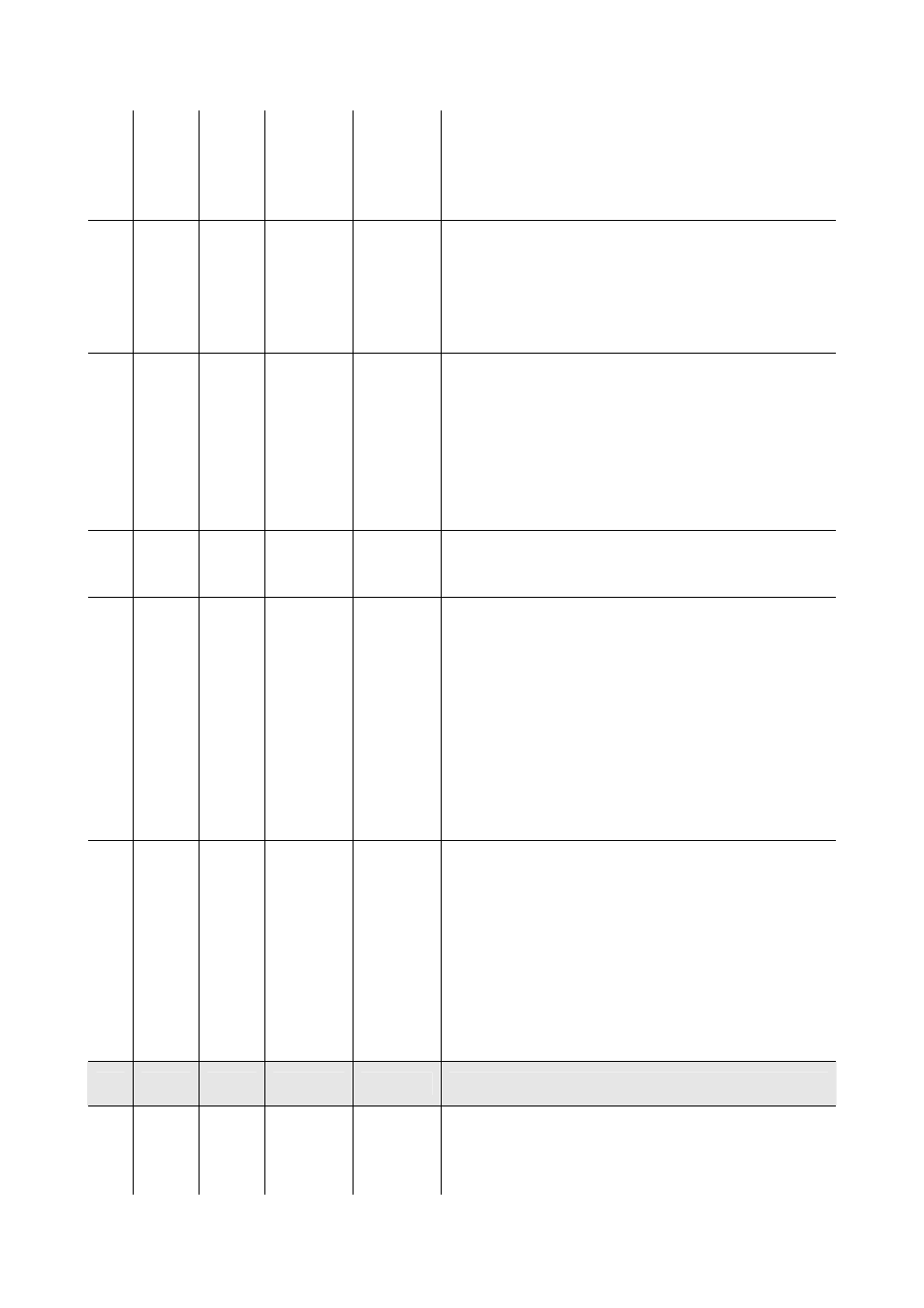

r15

-99

199

°C/°F (1)

65

temperature below which the count of the maximum

temperature-controlled

blast

chilling

and

maximum

temperature-controlled

deep

freezing

is

started

(temperature detected by the needle probe)

r16

0

2

- - - -

1

type of operating cycle that can be selected

0 = blast chilling and storage

1 = blast chilling and storage or deep freezing and

storage

2 = deep freezing and storage

r17

0

99

°C/°F (1)

5

"temperature detected by the needle probe - cabinet

temperature" minimum difference such to consider the first

phase of the test to verify correct insertion of the needle

probe completed successfully (consider the difference

without sign)

0 = the test will not be performed (neither first or second

phase)

r18

1

99

s

60

duration of the second phase of the test for verification of

correct insertion of the needle probe

r19

0

1

- - - -

0

quick modification value during the "On" status before

starting the operating cycle

0 = work set-point during blast chilling or during deep

freezing

1 = blast chilling or deep freezing end temperature

before starting a temperature-controlled cycle,

duration of blast chilling or deep freezing before

starting a time-controlled cycle (except before

starting a continuous blast chilling cycle or

continuous deep freezing cycle).

r20

0

1

- - - -

1

memorisation of the quick modification value during the

"On" status before starting the operating cycle

0 = no (on start-up of the successive same cycle, the

values established with parameters r7 and r3 or

those establishes with r4 and r8 will be re-proposed)

1 = yes (on start-up of the successive same cycle the

rapidly modified values will be re-proposed before

starting the previous same cycle)

Par.

Min.

Max.

Unit

Default

Compressor protections

C0

0

240

min

0

minimum time between restoring the power supply after a

power cut, occurring during an operating cycle and

compressor switch-on