Cub cadet commercial z-wing – Cub Cadet Z-Wing User Manual

Page 69

Cub Cadet Commercial Z-Wing

65

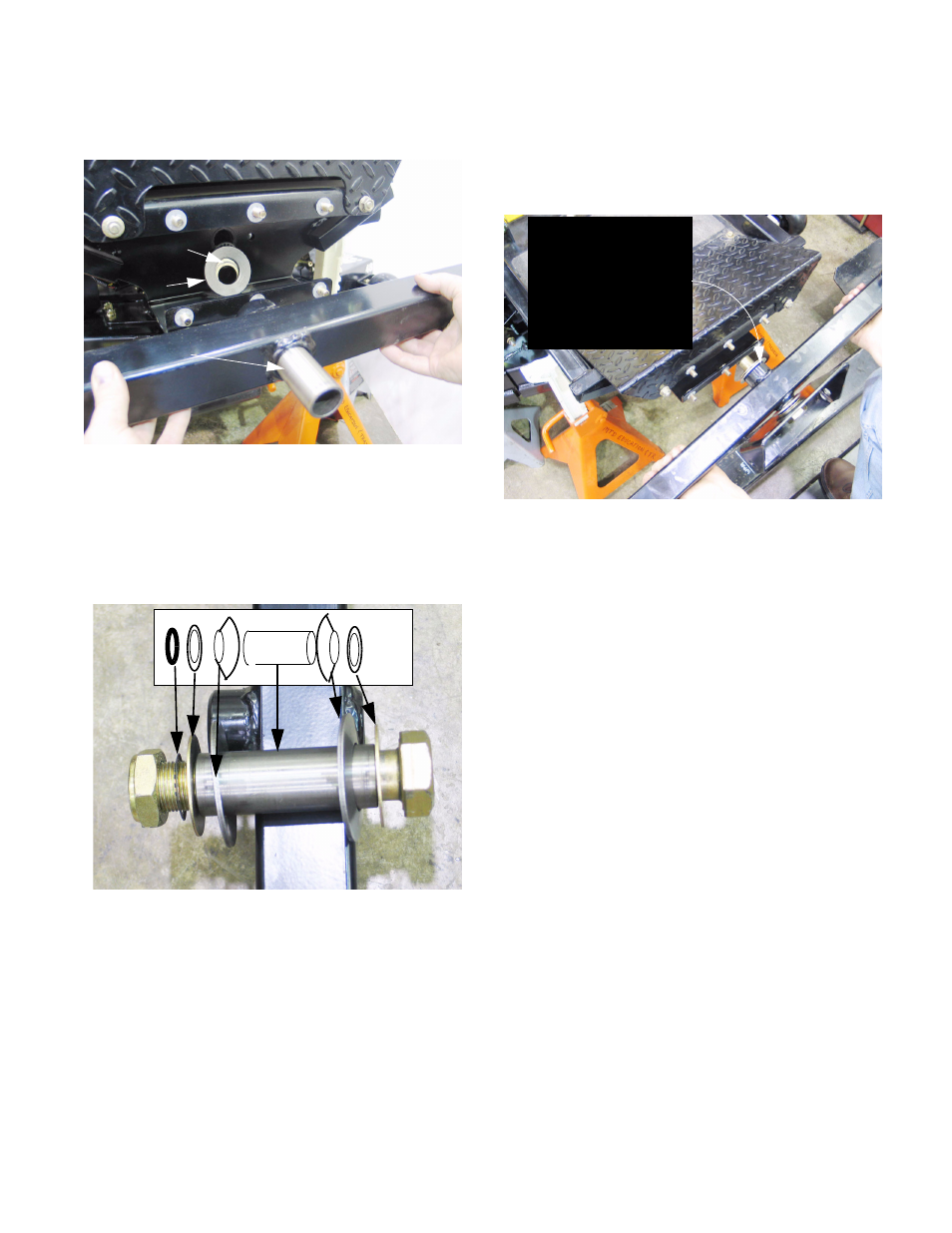

27.36.Lift the axle and spacer tube out of the frame.

27.37.Behind the axle and tube is a second belleville

washer and flat washer, positioned in mirror

image to the ones in front of the axle. Behind

them is a self-locking retainer.

27.38.Hardware orientation: See Figure 27.38.

Figure 27.36

Flat washer

Belleville

washer

Spacer tube

Figure 27.38

Rear

Front

27.39.For easiest installation, the axle bracket, axle,

pivot bolt, spacer tube, and washers can be

lubed and pre-assembled, with the self-locking

retainer holding all the parts in place.

See Figure 27.39.

27.40.Correct axle orientation:

•

The grease zerk on the pivot point faces down,

and the longer boss on the axle tube goes to the

rear.

•

The grease zerks for the caster yoke bearings

face rearward, and the tubes that the caster

yoke bearings fit in are of-set upwards from the

axle.

27.41.Install the nuts that secure the axle support

bracket. If the locking feature of the nuts has

worn, replace the nut or apply a small amount of

thread locking compound such as Loctite 242

(blue) to the threads and tighten them to a

torque of 35 ft-lbs (48 Nm).

27.42.Install the large locking nut that secures the pivot

bolt, and tighten it using a pair of 1 1/2”

wrenches. If the locking feature of the nut has

worn, replace the nut or apply a small amount of

thread locking compound such as Loctite 242

(blue) to the threads. Tighten the nut until all the

fore-aft play in the axle is taken-up, but not so

tight that friction inhibits the pivot action.

27.43.The remainder of the assembly process is to

reverse the steps of disassembly.

Figure 27.39

Washers

Pivot bolt

Axle bracket assembly

Axle

Pre-assembled,

ready for installation