Brake linkage adjustment, Cub cadet commercial z-wing – Cub Cadet Z-Wing User Manual

Page 45

Cub Cadet Commercial Z-Wing

41

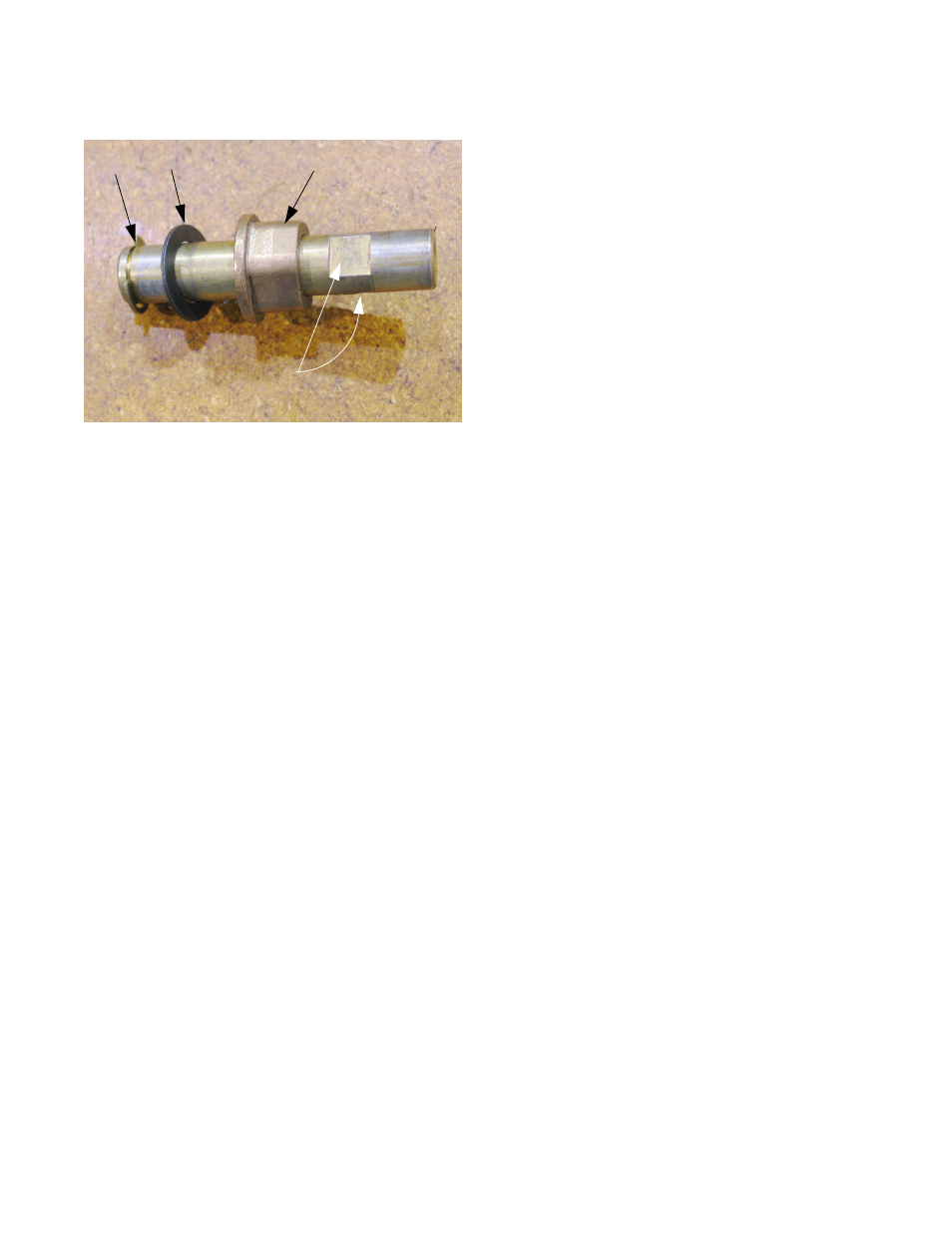

20.8. The steering pivot shaft.... See Figure 20.8.

20.9. Installation notes:

•

Apply lubricant to the friction surfaces of the

steering pivot shaft on assembly: In regions

where the mower will be in continuous duty, a

dry PTFE-based lubricant such as “Tri-flow dry

Teflon Lubricant” is appropriate. This will lubri-

cate the pivot shaft without collecting abrasive

grit. In regions where there is an extended dor-

mant period anti-seize compound will help keep

rust off the bearing surfaces during times of dis-

use.

•

Apply a small amount of thread locking com-

pound such as Loctite 242 (blue) to the threads

of the bolt that connects the steering pivot plate

to the steering pivot shaft. Tighten the bolt to a

torque of 35 ft-lbs (47.5 Nm).

•

If the locking feature of the nut that secures the

steering link rod has worn, replace the nut, or

apply a small amount of thread locking com-

pound such as Loctite 242 (blue) to the threads

of the bolt that connects the steering pivot plate

to the steering pivot shaft. Tighten the bolt to a

torque of 250 in-lbs (28.25 Nm).

20.10.Test the operation of the mower and its safety

features in a safe area that is clear of hazards,

obstacles, and other personnel before returning

it to service.

Figure 20.8

E-clip flat washer Inner hex flange bushing

Flats for wrench

21.

BRAKE LINKAGE ADJUSTMENT

21.1. Description: The brakes are cam-actuated shoe

brakes:

•

Because they are cam actuated, if they are mis-

adjusted in either direction, the brakes may drag,

or fail to hold the mower with sufficient force.

•

The brakes are generously sized. Because they

are parking brakes, not service brakes, shoe

wear is not likely to be a significant factor unless

the brakes have been dragging.

•

There is no internal brake adjustment such as a

star wheel: all adjustment is in the linkage.

•

There is a mechanical interlock between the

brake linkage and the steering pivot plate. While

there is interplay between the interlock and

brake actuation, the interlock is covered in the

next section of this manual: BRAKE / PIVOT

PLATE INTERLOCK.

21.2. The basic premise of brake adjustment is that

the brakes should keep the mower from moving

when they are applied, and should not drag

when they are released. This is quite simple.

Brakes that drag can be referred to as too tight.

Brakes that fail to hold the mower with sufficient

force can be referred to as too loose.

21.3. Tight brakes are characterized by:

•

The mower cannot be manually pushed (nor the

wheels rotated) with reasonable effort, with the

brake released and the relief valves open.

•

The mower has persistent tracking issues, even

after the tracking adjustments have been cor-

rectly performed.

•

The wheel motor on one or both sides of the

mower creates an unusual amount of noise and

heat. The noise may be a “chatter”, a “whine” or

a “groan”. The noise will be immediate, though it

may change with use. The temperature will go

up rapidly in the first 15 minutes of use.

•

Heat will be generated not only by the friction of

the brake, but also by the increased loads on the

hydro pumps and wheel motors. The tempera-

ture of the fluid in the drive system will climb rap-

idly. High temperatures will significantly shorten

the service life of the pumps and motors. Dam-

age or failure of these components that results

from continued operation with a dragging brake

is not warrantable. It is the customer’s responsi-

bility to recognize when the performance of their

equipment degrades, and ensure that proper

repairs or maintenance are done.