Cub cadet commercial z-wing – Cub Cadet Z-Wing User Manual

Page 47

Cub Cadet Commercial Z-Wing

43

21.9. Park the mower on a flat, firm, level surface, the

engine turned-off, and the hydro relief valves

open.

NOTE: If the mower has been run recently allow

the engine and drive system to cool long enough

to avoid burn injuries before beginning adjust-

ment.

NOTE: Relief valves are located on the back of

each pump, immediately below the pivot brake

shaft.

NOTE: This test can also be performed with the

rear of the mower lifted and safely supported on

jack stands. In this case the wheels would sim-

ply be rotated by hand rather than trying to push

the entire mower.

21.10.Release the parking brake.

21.11. Attempt to push (rotate) the right rear wheel of

the mower in either direction. There will be some

motor drag on the wheel, but it should rotate with

reasonable effort.

21.12.If the wheel will not rotate, or there is doubt as to

whether the brake is fully released or not, loosen

the adjustment nut until the wheel will rotate.

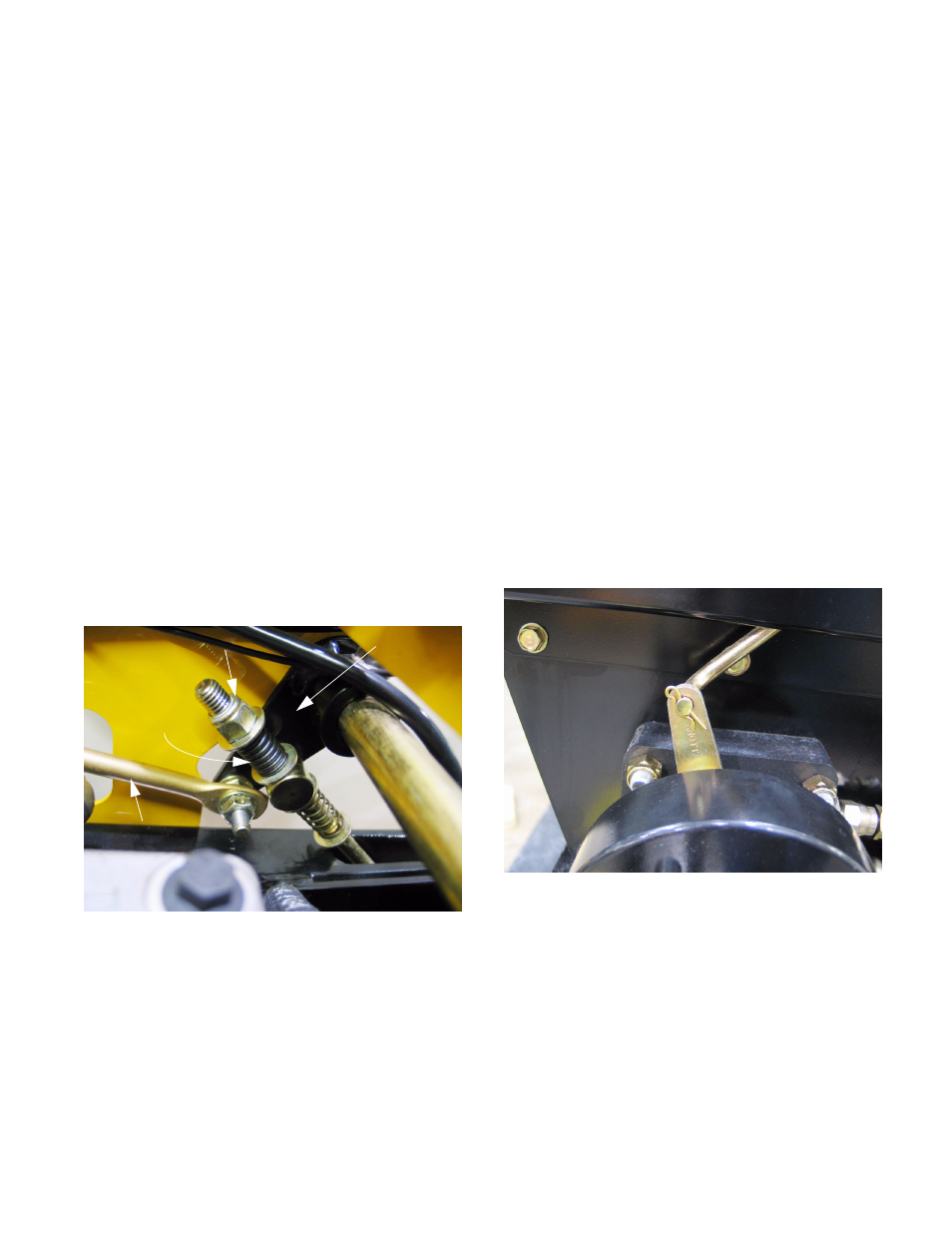

See Figure 21.12.

21.13.If loosening the nut does not allow the wheel to

rotate as it should, check the position of the arm

on the brake cam, as described later in this sec-

tion of the manual.

21.14.Engage the parking brake.

21.15.Attempt to push (rotate) the right rear wheel of

the mower in either direction. It should not turn.

Figure 21.12

Steering lock rod

Brake adjustment nut

Output arm

Compression

spring

(brake ON)

21.16.If the wheel does rotate, tighten the adjusting nut

in half-turn increments until the wheel is held

firmly.

21.17.Release the parking brake, and confirm that it

does not drag.

21.18.Repeat and adjust as necessary to assure cor-

rect brake operation.

21.19.Repeat the process on the left rear wheel.

21.20.When making brake adjustments, remember:

•

There is about 1.5” (3.8cm) of thread length on

the end of the brake rod.

•

The nut is roughly 1/2” (1.27cm) tall, including

the nylon locking ring.

•

If 1” (2.54cm) of threaded rod is exposed above

the nut, the nut is bottomed-out, and out of

adjustment range.

21.21.If the nut bottoms-out or tops-out (the nylon lock-

ing ring reaches the end of the threads on the

brake rod) before correct adjustment is

achieved, the brake arm may be mis-indexed.

See Figure 21.21.

NOTE: This is not a likely occurrence unless it

was improperly assembled, or someone unquali-

fied to work on the brakes has tampered with it.

21.22.To reach the brake adjustment arm:

•

Loosen the lug nuts using a 3/4” wrench.

•

Lift, and safely support the back of the mower,

raising the rear wheels off the ground.

•

Remove the rear wheels.

Figure 21.21