Hydraulic drive system: diagnosis, Cub cadet commercial z-wing – Cub Cadet Z-Wing User Manual

Page 54

Cub Cadet Commercial Z-Wing

50

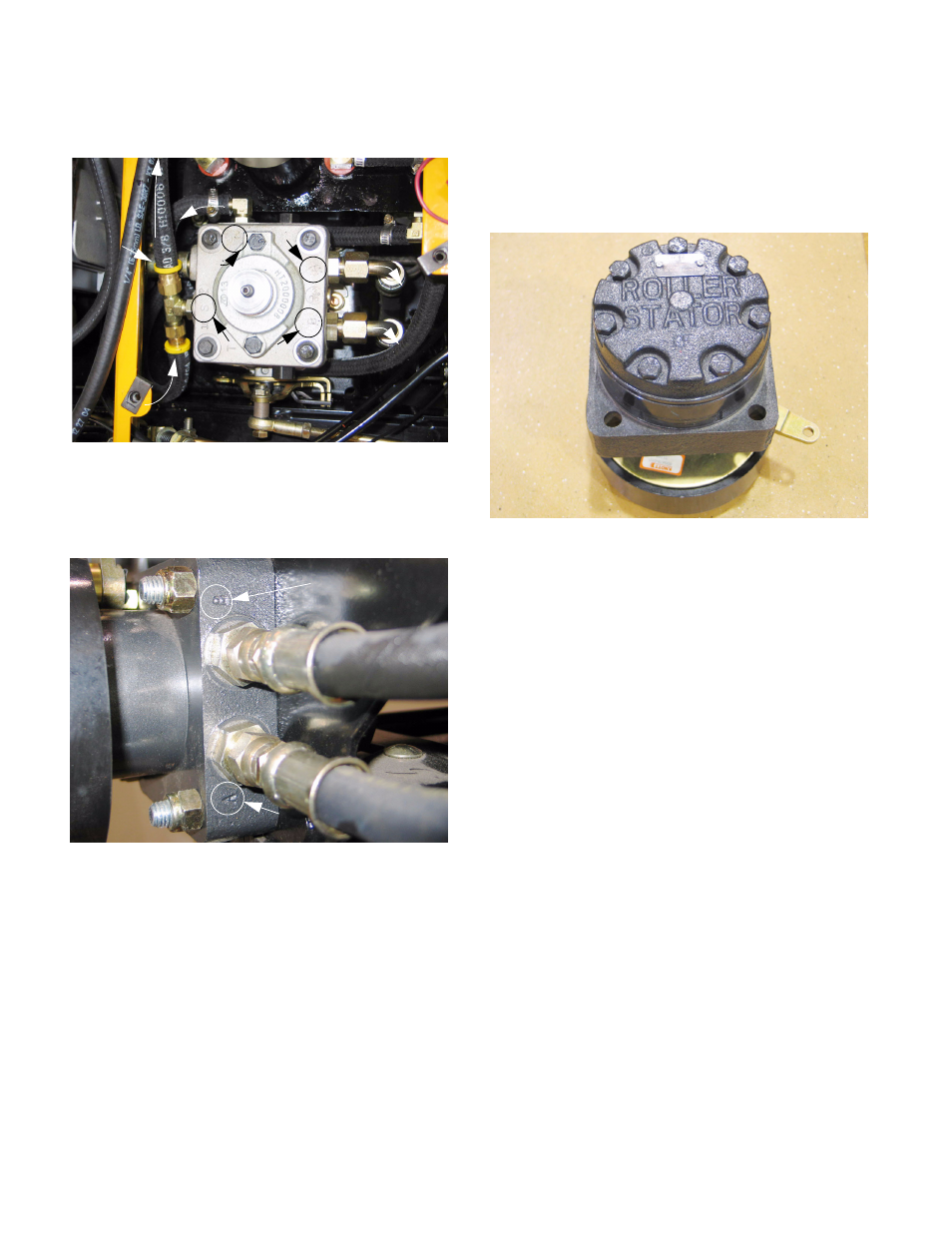

23.8. The fluid will also drain out of the lines leading to

the pumps. See Figure 23.8.

23.9. The heavier hoses carry pressurized fluid

between the pumps and the wheel motors.

See Figure 23.9.

•

The right side pump and wheel motor are

plumbed “A” to “B” and “B” to “A”.

•

The left side pump and wheel motor are

plumbed “A” to “A” and “B” to “B”.

•

This is necessary because two identical pumps

are driven in the same direction, but mounted in

a mirror-image relationship to one another. The

mounting reverses the direction of the control

inputs to one pump.

23.10.The wheel motors are manufactured by White

Hydraulics. There is no financial nor managerial

relationship between White Hydraulics and

White Outdoor Power. They are a separate

company, and Cub Cadet Commercial is simply

a customer. See Figure 23.10.

•

White wheel motors feature a unique roller stator

design: The rollers reduce friction directly and

recover an oil film faster than a standard fixed

surface.

•

For more information, visit:

//WWW.Whitehydraulics.com

•

The model used here is of the CE Series.

24.

HYDRAULIC DRIVE SYSTEM: DIAGNOSIS

24.1. The method used for testing the pumps is called

a “Flow Droop” test.

•

The flow rate is tested at a pressure of 300 PSI,

and again at 1,100 PSI. The two flow rates are

compared to determine if the pump is damaged.

•

If the pump is determined good, and there are no

external factors hurting the performance of the

drive system, then the motor can be determined

to be at fault through the process of elimination.

24.2. Before condemning (or even testing) a pump or

motor, a variety of external factors should be

checked. These include:

•

Dragging brake

•

Wrong fluid or filter

•

Leak or fluid starvation

•

Partially open relief valve

•

Belt / tensioner issues

Figure 23.8

From filter

To other pump

NOTE: cooling

fan removed

for visibility

To tank (reservoir)

“S”

“T”

“B”

“A”

To Wheel

motor

Relief

valve

Figure 23.9

“B”

“A”

Figure 23.10