Hydraulic drive system: general operation, Cub cadet commercial z-wing – Cub Cadet Z-Wing User Manual

Page 52

Cub Cadet Commercial Z-Wing

48

22.12.Installation notes:

•

Apply lubricant to the friction surfaces of the

steering pivot shaft on assembly: In regions

where the mower will be in continuous duty, a

dry PTFE-based lubricant such as “Tri-flow dry

Teflon Lubricant” is appropriate. This will lubri-

cate the pivot shaft without collecting abrasive

grit. In regions where there is an extended dor-

mant period anti-seize compound will help keep

rust off the bearing surfaces during times of dis-

use.

•

If the locking feature of the nuts that secure the

steering lock rods or brake links has worn,

replace the nut, or apply a small amount of

thread locking compound such as Loctite 242

(blue) to the threads of the bolt that connects the

steering pivot plate to the steering pivot shaft.

Tighten the bolt to a torque of 250 in-lbs (28.25

Nm).

•

If the locking feature of the nuts that secure the

input and output arms to the brake pivot shaft

has worn, replace the nut, or apply a small

amount of thread locking compound such as

Loctite 242 (blue) to the threads of the nut.

Tighten the nut to a torque of 250 in-lbs (28.25

Nm).

22.13.Test the operation of the steering and brake con-

trols, and all related safety features before

returning the mower to service. Tests should be

done in a clear area that is free of hazards,

obstructions, and other personnel.

23.

HYDRAULIC DRIVE SYSTEM: GENERAL

OPERATION

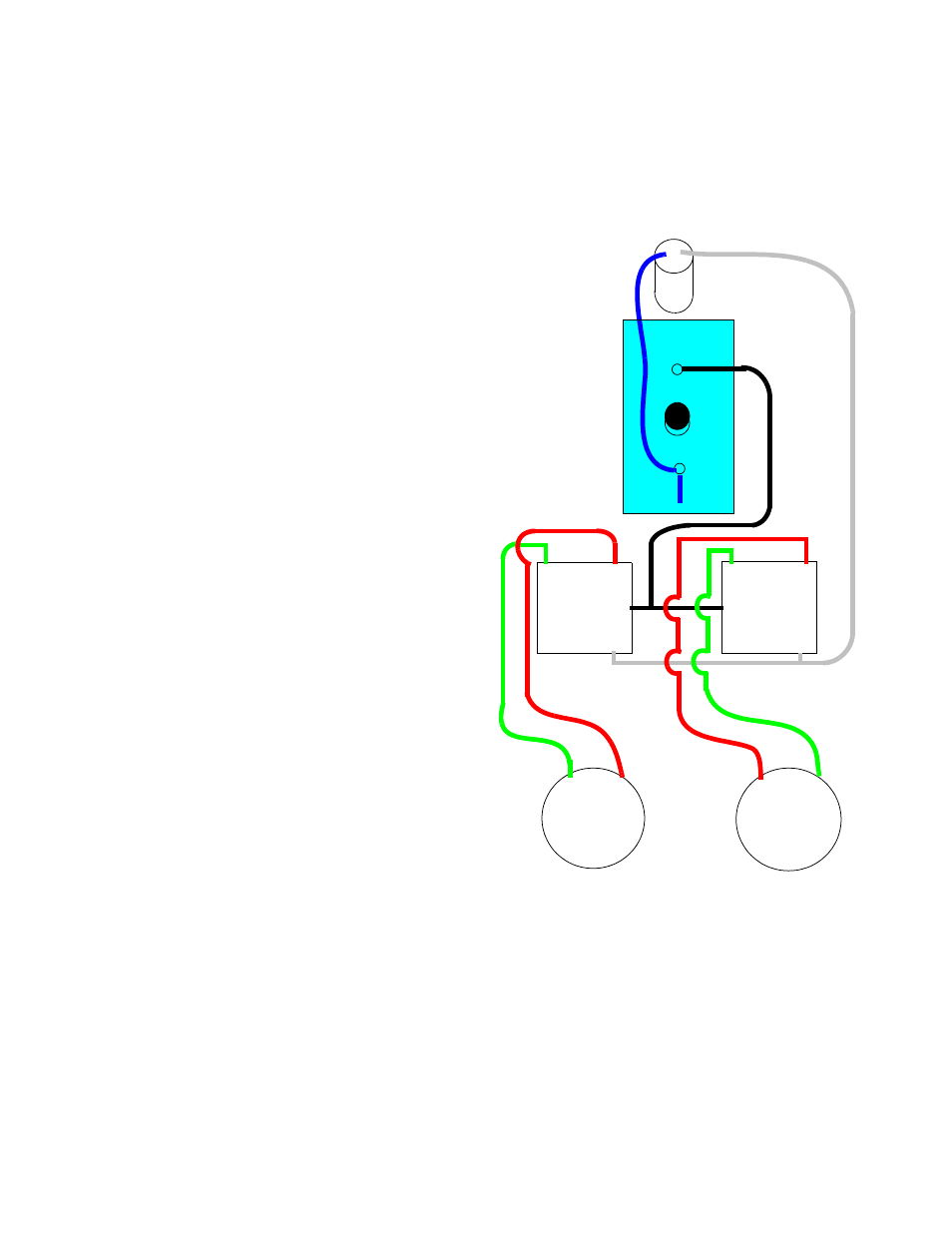

23.1. System diagram: See Figure 23.1.

Front of mower

Filter

Reservoir

Pick-up

Return

A

B

A

B

T T

S S

Pump Pump

Left Right

A

B

A

B

Left Wheel Right Wheel

Motor Motor

Fill

Figure 23.1