Cub cadet commercial z-wing – Cub Cadet Z-Wing User Manual

Page 64

Cub Cadet Commercial Z-Wing

60

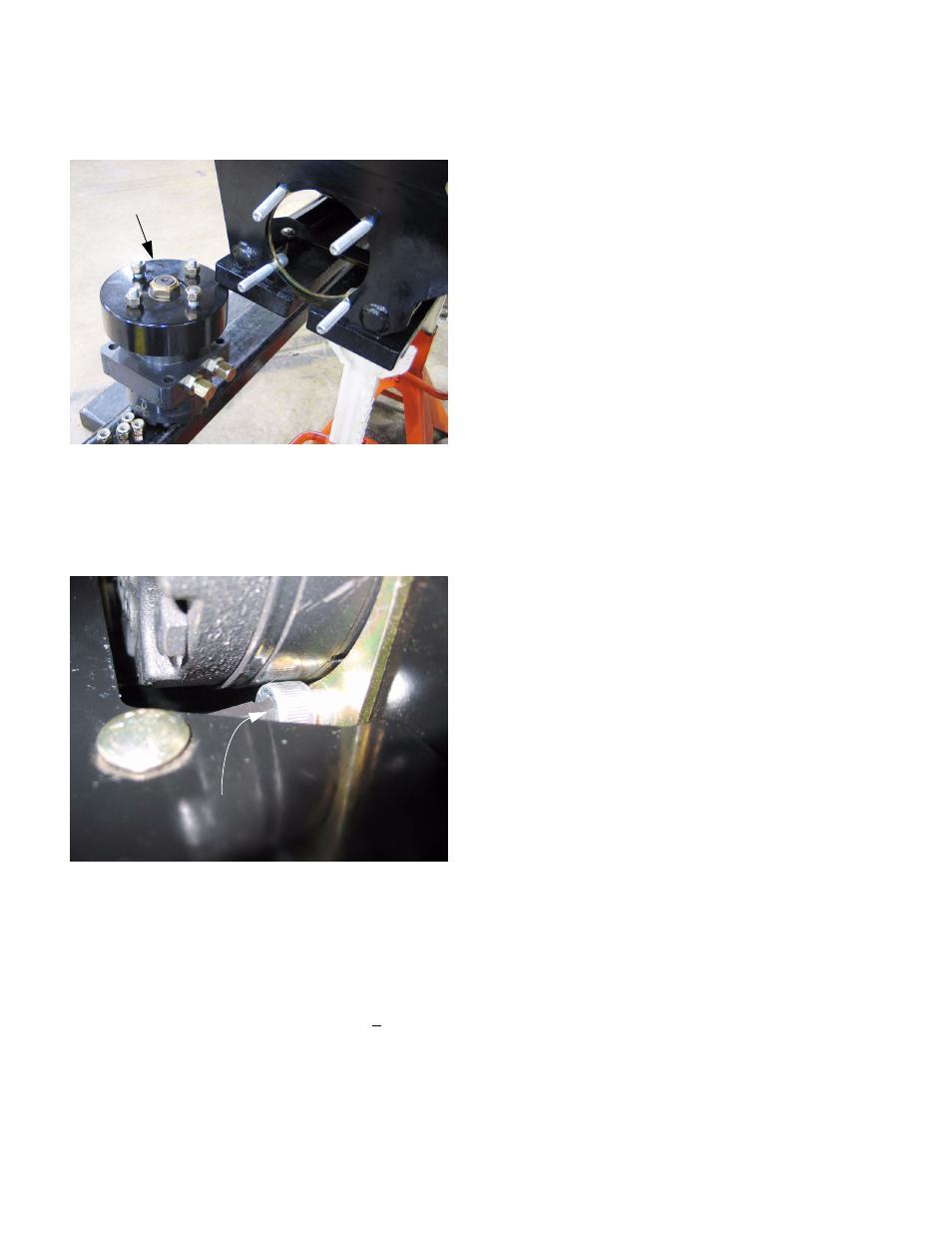

26.11. Reverse the removal process to install the wheel

motor. See Figure 26.11.

26.12.Access to the socket head cap screws around

the weights is tight. Once in position, a ball drive

allen wrench can be wedged against the weights

to ease installation. See Figure 26.12.

•

If the locking feature of the nut has worn, replace

the nut, or apply a small amount of thread lock-

ing compound such as Loctite 242 (blue) to the

threads. Tighten the nut to a torque of 80 ft-lbs

(108.48 Nm).

•

Tighten the lug nuts to a torque of 60 +10 ft-lbs

(68-95 Nm).

26.13.Re-fill the reservoir with Hydraulic Drive System

Fluid Plus.

26.14.Confirm that no hazardous condition will be cre-

ated by running the engine or operating the drive

system.

26.15.Open the relief valve of the pump that drives the

newly replaced wheel motor.

26.16.Start the engine and purge the drive system:

•

Give the lap bar ten strokes over the full distance

of it’s travel, taking about 10 seconds to com-

plete each stroke.

•

Turn off the engine. Check the fluid level and

top-up if necessary. Check for leaks. Close the

relief valve.

•

Start the engine.

•

Give the lap bar ten strokes over the full distance

of it’s travel, taking about 10 seconds to com-

plete each stroke.

•

Turn off the engine. Check the fluid level and

top-up if necessary. Check for leaks. Close the

relief valve.

•

Lower the rear of the mower to the ground.

26.17.Adjust tracking as necessary.

26.18.Test the operation of the mower and its safety

features in a safe area that is clear of hazards,

obstacles, and other personnel before returning

it to service. Some growling noise may come

from the drive system until all the air is purged.

Figure 26.11

Wheel motor

removed

Figure 26.12

Ball drive Allen wrench