Cub cadet commercial z-wing – Cub Cadet Z-Wing User Manual

Page 55

Cub Cadet Commercial Z-Wing

51

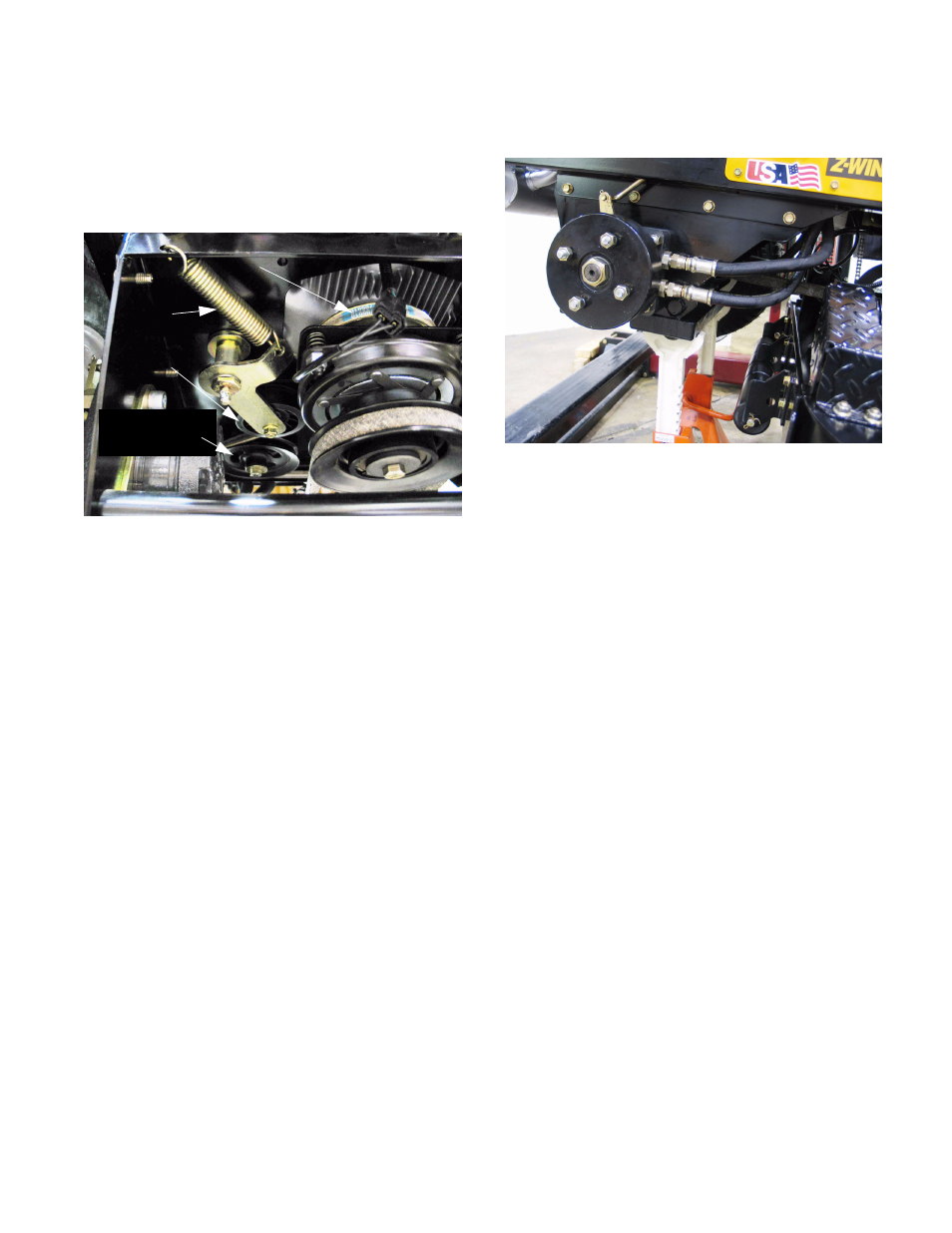

24.3. If the performance of the right side drive system

is suspect, pay particular attention to the belt

and tensioner. There is more belt wrap on the

left pump pulley than the right because the ten-

sioner is on the left side of the frame.

See Figure 24.3.

24.4. Observe normal hydraulic precautions:

•

Allow the engine and drive system to cool before

disconnecting any fittings that may expose the

technician to hydraulic fluid.

•

If the hydraulic system or gauge set develop any

leaks in the course of operation or testing: dis-

continue operation immediately, identify and

repair the leak.

•

Relieve pressure from the system before discon-

necting any components or fittings: with the

engine and brake off, stroke the controls through

their full range of motion.

•

Clean the area surrounding any components or

fittings to be disconnected to prevent contamina-

tion of the hydraulic fluid.

•

Clean-up any spilled fluid promptly to prevent

accidents.

•

Wear eye protection while working on hydraulic

systems.

24.5. Lift and safely support the rear of the mower.

Figure 24.3

Belt

Tensioner

spring

Tensioner

pulley

Pulley, left side

hydro. pump

24.6. Remove the wheels using a 3/4” wrench.

24.7. The gauge set should be connected so that the

fluid enters the gauge set from the pressure

gauge side and exits through the flow meter

side. There are a variety of way to accomplish

this. Bear in mind that:

•

Valid tests can be made in the forward or

reverse direction.

•

Valid tests can be performed with or without the

wheel motor in the hydraulic circuit.

•

Disconnecting just one hydraulic line from the

wheel motor, and installing the gauge set in

series with the motor is slightly less work than

disconnecting both lines

•

Fluid flow: In forward motion, fluid enters the

wheel motor through the upper “B” port on the

motor and exits through the lower “A” port.

•

Either port may be used:

The gauge set would be connected with the flow

meter nearest the wheel motor if the “B” port is

used and the test is made with forward wheel

motion.

The gauge set would be connected with the

pressure gauge nearest the wheel motor if the

“A” port is used and the test is made with for-

ward wheel motion.

24.8. Configure the test kit for the intended installa-

tion, with fittings finger-tight to facilitate adjust-

ment. Keep it within arm’s reach along with any

wrenches needed to tighten the fittings. Set-up

and wrench sizes may vary.

Figure 24.6