Controller testing, System troubleshooting, Controller testing system troubleshooting – KMC Controls CSP-5002 User Manual

Page 5: Caution

CSP-5001/5002 VAV Flow Controller-Actuators

5

Applications Guide, Rev. B

System Troubleshooting

The following troubleshooting guide is directed

towards single duct cooling applications, the same

concepts can be applied to other configurations.

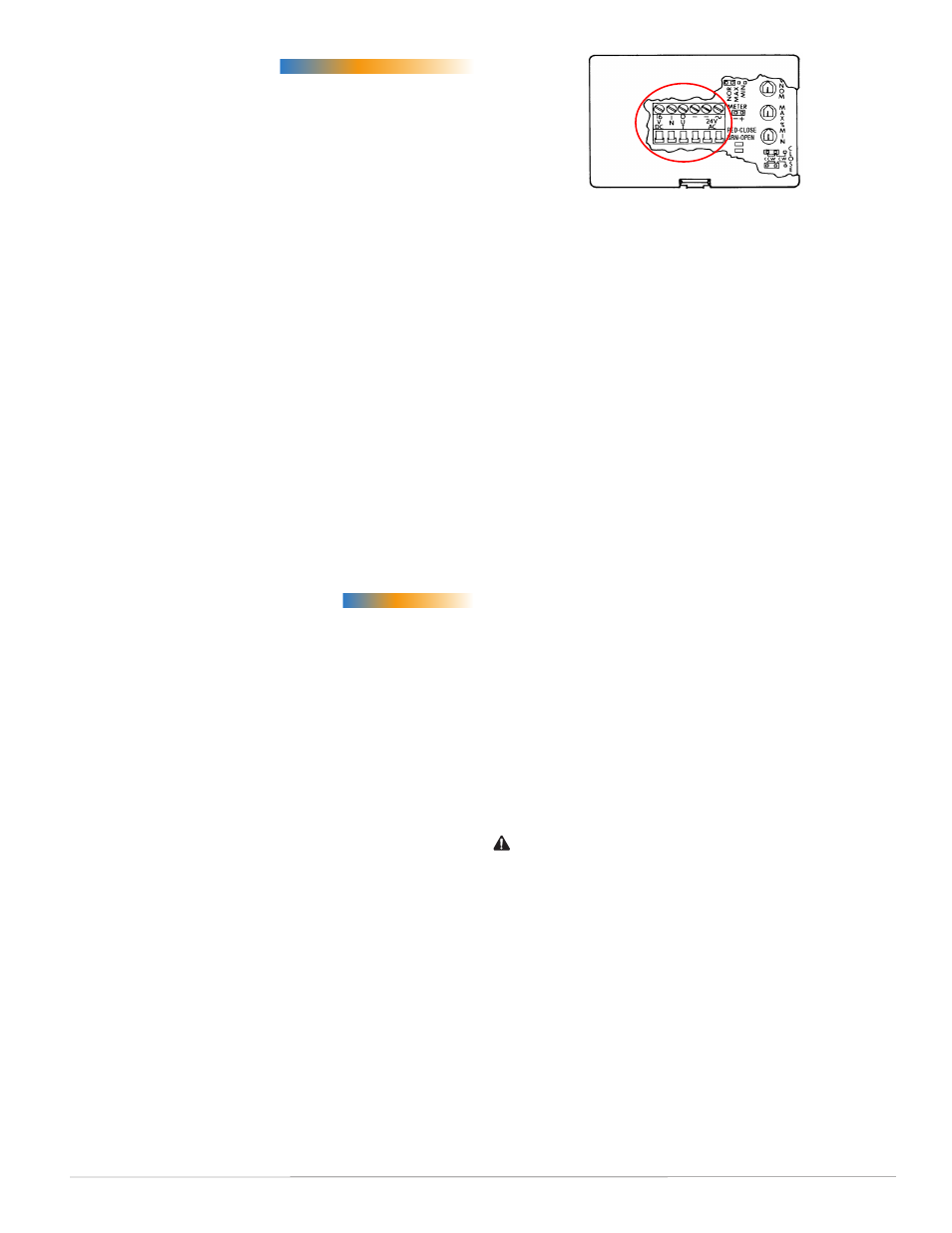

1. Verify 24 volts AC at terminals “~” (phase) and

“–” (ground). Tolerance can be –15% to +20%

(20.4 to 28.8 volts AC)

NOTE: When using the same transformer for more

than one control, the phase and ground

must be consistent with each device.

2. Verify 16 volts DC at terminals “(16 VDC)” and

“(–)”. Tolerance is 15.0 to 17.0 volts DC, power

supply to thermostat. If not correct, disconnect

the thermostat and recheck. If still incorrect,

replace the CSP controller.

3. Check “Requested Flow” voltage on the “IN” and

“–” terminals. Use the Typical Voltage/Velocity

Chart to correlate the voltage with air flow.

4. Check “Actual Flow” voltage on terminal “OUT”

and “–” for (0–10 volts DC). The “IN” and “OUT”

voltages should match (within a reasonable

tolerance). If they do not, change the setpoint all

the way up or down, wait at least five minutes,

and measure again. If they still do not match,

check for the following:

Controller Testing

Test the CSP actuator’s motor operation:

1. Temporarily disconnect the thermostat reset

connection at Terminal “IN”.

2. Jumper “IN” terminal to the “16 VDC” terminal.

The green Open LED should illuminate. The

shaft drive hub should be rotating the damper

open. The damper should go to full open unless

the maximum limit was set at the CSP, and then

the damper will only go to the maximum setting.

If the damper is rotating closed, the “Close”

jumpers must be changed. Refer to the Rotation

Setup section.

3. Jumper “IN” terminal to the “–” terminal. The

red Close LED should illuminate. The shaft

drive hub should be rotating the damper closed.

The damper should go to full closed unless the

minimum limit was set at the CSP, and then the

damper will only go to the minimum setting. If

the damper is rotating open, the “Close” jumpers

must be changed. Refer to Rotation Setup section.

A. There is inadequate airflow in the duct leading

to the controller.

B. The damper may be sticking or at the end of

its travel.

C. The setscrews on the actuator shaft may be

slipping.

D. The VNOM potentiometer may have been

changed from its factory setting. See the

VNOM Range Setting section.

5. If the “Requested Flow” and “Actual Flow”

match, but the reading from a flow hood over the

duct outlet is substantially different, one of the

following may be at fault:

A. The tubing to the controller’s flow sensor

may be kinked, too long, or pulled off (fix the

tubing).

B. The flow sensor in the controller may be bad

(replace the controller).

6. Check box movement, damper rotation, etc.

A. Review “Requested Flow” and “Actual Flow”

above to determine if unit should be satisfied

(within 50 fpm) or driving open or closed.

B. If damper is not moving, verify damper is

not stuck or at end of travel. Check rotation

jumpers for proper position.

C. Change “Requested Flow “ to drive the

unit in the opposite direction. This can be

accomplished by moving the setpoint sliders

or the steps below.

CAUTION

Never jumper terminal “16 VDC” to terminal

“–” since this would cause a short and possibly

damage the power supply.

i. To manually open the box, remove wiring

from terminal “IN” and jumper terminal

“IN” to terminal “16 VDC”. This will tell

unit to control at 3300 fpm (full airflow),

the green LED should turn on, and the box

should drive open).

ii. To manually close the box, remove wir-

ing from terminal “IN”, and jumper “IN”

terminal to “–” terminal. This will tell unit

to control at zero fpm (no airflow), the red

LED should be on and the box should drive

closed.