Ec b (a) (b) – Elecraft KPA100 Manual User Manual

Page 38

38

Using your DMM's lowest resistance scale, check for continuity (< 1

ohm) between one set screw and all of the others.

Pedestal

H

H

H

H

H

S

S

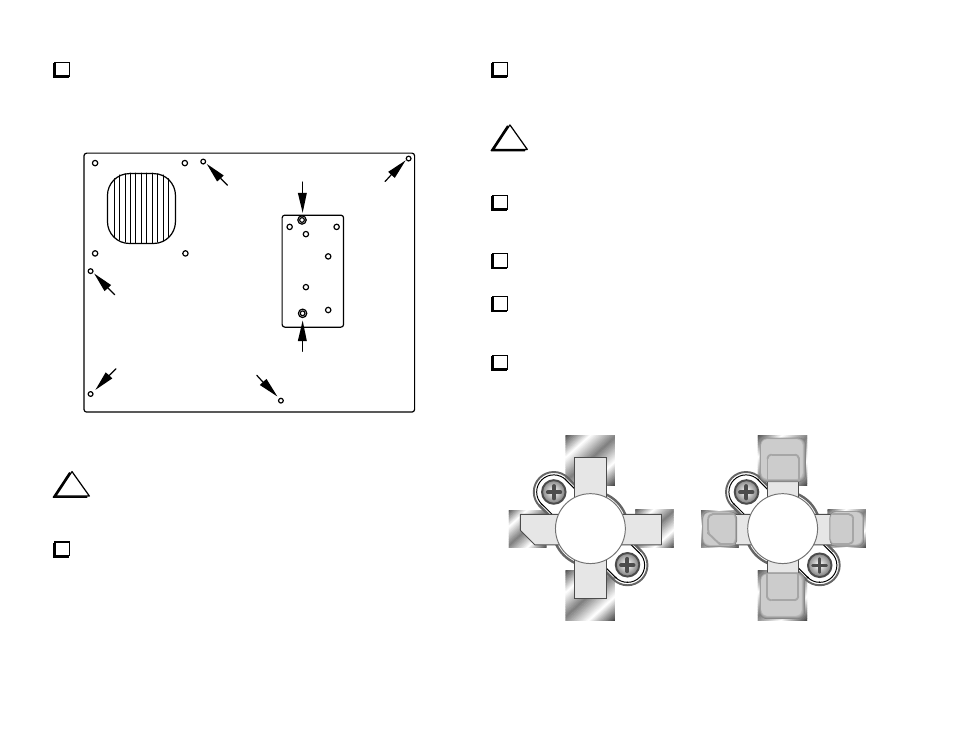

Figure 29

i

The leads of some components near the power transistors

must be flush-trimmed as explained in the next step. This will prevent

leads from shorting to the pedestal.

Flush-trim the leads of the components listed below on the bottom of

the board. The leads must be less than 1/32" (0.7 mm) long.

__ C40

__ C50

__ C80

__ C81

__ C58

__ C59

__ C31

__ L18 (jumper)

__ Z1

__ L16

Over the rest of the board, trim any component leads that you may

have missed earlier, including connector leads. Use a ruler to make sure

that all leads are trimmed to less than 1/8" (3 mm).

i

The PC board will be attached to the heat sink temporarily in

the next step. This will position the power transistors correctly for

soldering. Do not install thermal pads at this time.

Place the KPA100 PC board assembly on top of the heat sink.

Secure the board to the heat sink at the pedestal set screws using 1/2"

(12.5 mm) long standoffs. Thread them on hand-tight only.

Locate the two flange-mount power transistors. If the tabs are bent,

straighten them carefully using long-nose pliers.

Pre-tin the tabs of Q1/Q2 (top and bottom) with a small amount of

solder. Also pre-tin the pads for Q1 and Q2 on the PC board. A high-

wattage iron will be required to tin the emitter pads.

Place power transistors at Q1 and Q2, orienting the four tabs as

shown in Figure 30a. The notched tab must be aligned with the PCB

pad labeled "C" (collector).

E

E

C

B

(a)

(b)

Figure 30