Assembly, part ii – Elecraft KPA100 Manual User Manual

Page 27

27

Assembly, Part II

A number of toroidal inductors are used on the KPA100 PC board.

1

The

first inductor to be wound uses a type T50-10 core. The letter T identifies

this as an iron-powder core. 50 specifies the outside diameter in

hundredths of an inch, in this case 0.5 inches (12.7 mm). The -10 suffix

refers to the core type and color, in this case a black iron-powder core.

There are also two ferrite toroid cores used, such as type FT37-61. In this

part number, FT identifies the core as ferrite, and 37 is the size (0.37", 9.5

mm). The -61 identifies the type of ferrite, although all the ferrite cores

are dark gray in color. (There are also two "binocular" ferrite cores in the

kit, which will be described later.)

Three types of enamel wire are supplied with the kit: #22 red, #26 red,

and #26 green. #22 wire is much larger in diameter than #26. Be sure to

use only the type called for in the instructions; do not substitute other wire

types. Cut wires to the specified lengths to avoid running out of wire.

Eight black iron-powder toroid cores are supplied with the kit.

These are type T50-10 (0.5" [12.7 mm] dia.). Locate one of these cores

for use at L4. (Don't use the dull-gray FT50-43 core.)

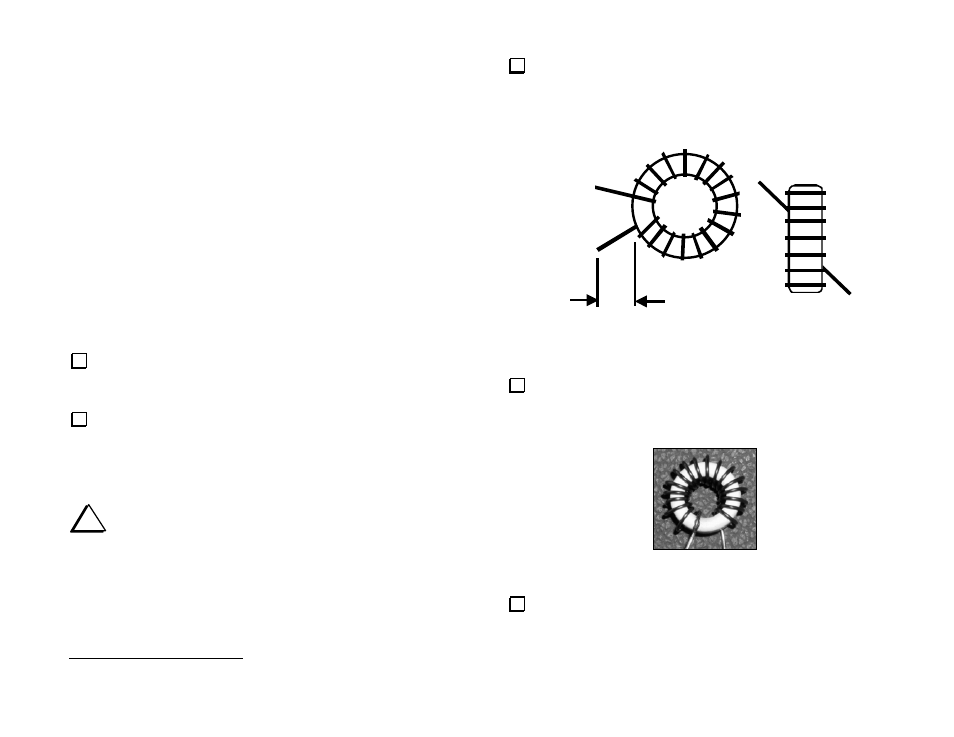

Find the component outline for L4, at the left side of the board near

relay K5. Compare this component outline to Figure 16, which shows two

views of a typical toroidal inductor. L4 will be mounted vertically as

shown at the right side of the drawing, with one wire exiting at the core’s

upper left, and the other at the lower right.

i

#22 enamel wire is fairly stiff, and may be difficult to wind

tightly onto the core. The turns should not be loose, but it is

acceptable to have a very small gap between the wire and the core's

flat surfaces. If you try to wind #22 so that it "hugs" the core all the

away around, you may have to pull the wire too hard, resulting in

hand fatigue.

1

Pre-wound toroids are available from an Elecraft-approved source; see page 3.

Cut 15 inches (37 cm) of #22 red enamel wire. To wind L4, "sew"

the long end of the wire through the T50-10 core. Each pass through the

core counts as one turn. 17 turns are needed, as shown in Figure 16. The

enamel insulation will be removed in a later step.

Remov e insu lation

Figure 16

Verify that the turns of L4 are not bunched together. They should be

evenly spaced, and should occupy about 80-90% of the core. Proper turns

spacing is shown in the photograph below (Figure 17).

Figure 17

Toroids shown in photos are wound on white cores to highlight turns

counts and spacing. Place L4 on top of the photo above, then adjust the

turns spacing until it is similar to that shown.