Metrohm 833 IC Liquid Handling Unit User Manual

Page 85

9.1 Faults and their remedies

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

77

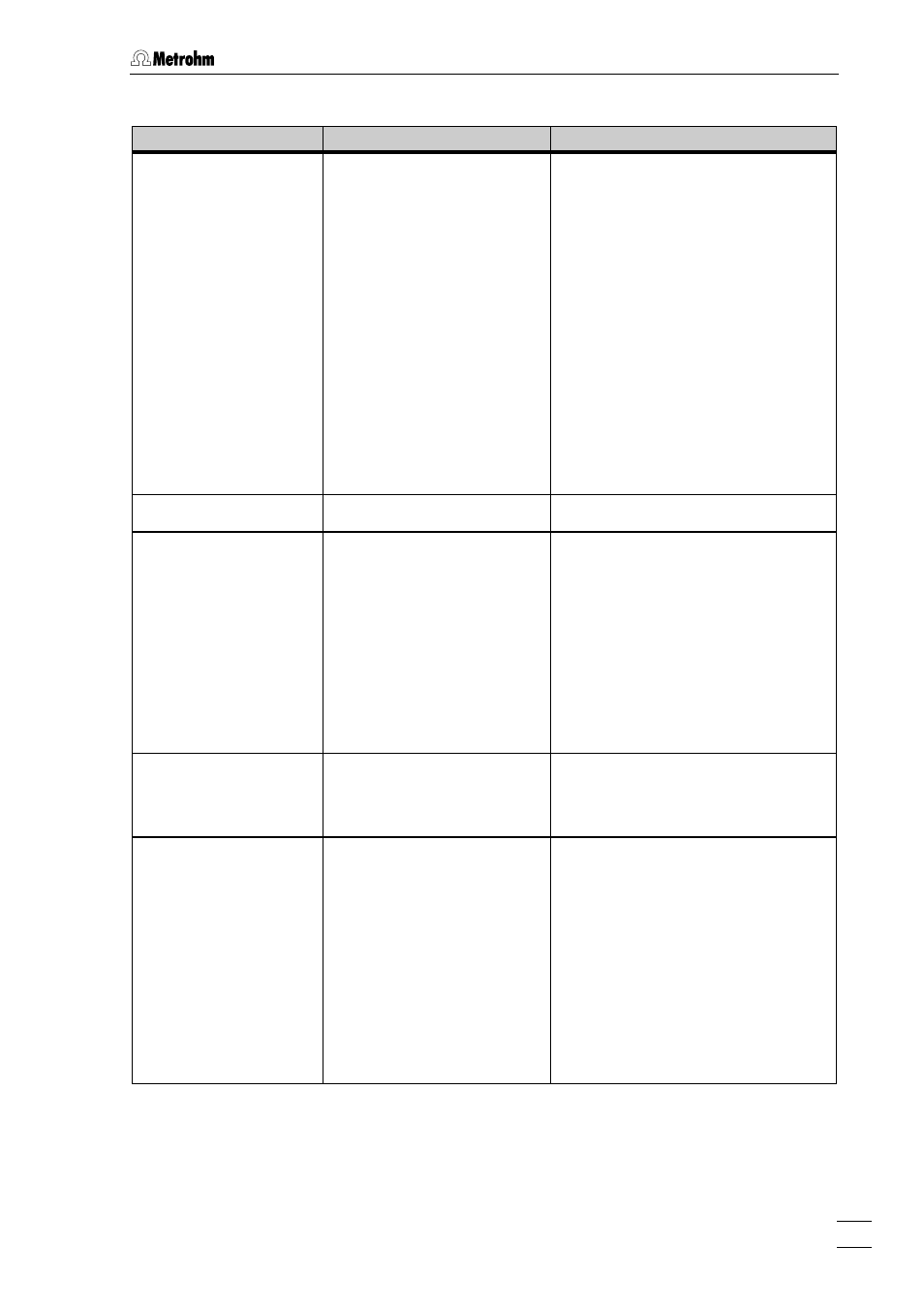

Fault

Cause

Remedy

Inadequate or no supply

at all from pump

Dialysis cell

•

Dialysis cell inlets blocked

•

Sample tubing blocked by too

large particles

•

Bacterial growth in sample

channel and dialysis cell

•

Narrowed PTFE tubing by

compression fittings tightened

too much

Filtration cell

•

Filter membrane blocked,

filtration cell inlets blocked

•

Narrowed PTFE tubing by

compression fittings tightened

too much

•

Replace dialysis membrane and clean

the cell (see Section 9.2.7.1).

•

Replace blocked tubing, always

centrifuge sample (see Section 9.2.4).

•

Replace tubing16, 57 und 58 for sample

channel regularly, replace dialysis

membrane

•

Use capillary cutter to cut off narrowed

tubing ends or replace tubing.

•

Replace filter membrane and clean the

cell (see Section 9.2.8.1).

•

Use capillary cutter to cut off narrowed

tubing ends or replace tubing.

Leaks

•

Tubing nipple leaks

•

Tighten up or replace tubing nipples.

Air bubbles in pump

circulation system

•

Aspiration tubing not immersed

•

Tubing nipple leaks

Dialysis cell

•

Acceptor not properly

degassed

•

Standing air bubbles

•

Completely immerse aspiration tubing.

•

Tighten up or replace tubing nipples.

Dialysis cell

•

Degas acceptor solution again.

•

Small air bubbles do not interfere. For

larger air bubbles rinse the sample

channel with degassed acceptor solution

(possibly open outlet briefly).

Reduced phosphate

sensitivity and/or large

baseline increase

(suppressor)

•

Suppressor capacity reduced

by heavy metal load or organic

contaminants

•

Regenerate suppressor (see Section

9.2.6.1) or replace it (see Section 9.2.6.3).

Suppressor module /

Sample preparation

module switches to next

position, but does not

work properly

•

Suppressor module/Sample

preparation module dry

•

Actuator rotor temporarily in

wrong position

•

Actuator step not set correctly

•

Rinse all 3 actuator units with solution for

at least 10 min.

•

Switch instrument off and on again.

Activate suppressor with

that actuator rotor is in correct position

(see Section 9.2.6.3).

Repeat process 2-3 times, before each

switch to next position with

at least 10 s.

If necessary set actuator step again (see

below).

•

Readjust actuator step

(see Section 9.2.6.3).