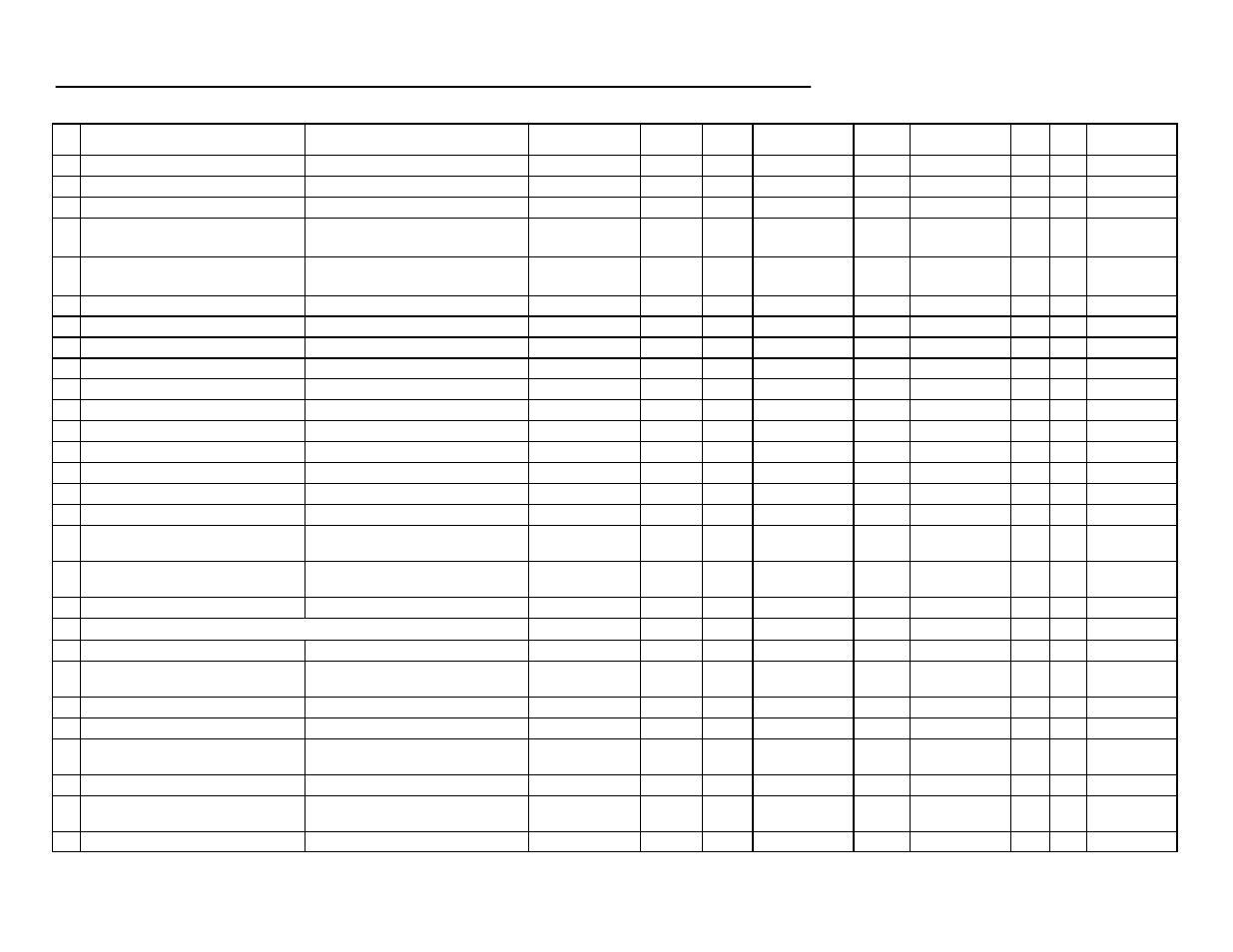

Offset data – Rockwell Automation 8520-9API 9/Series OCI API Developer's Guide User Manual

Page 196

OCI Data Items

A–8

Publication 8520-6.6. - August 1999

Control Type

Req

Dual

Proc.

Units

Dependency

Units

Array Indices

Num

Indices

OCI/9/PC

Data Type

Description

Item (Name)

175

MACHINE_TYPE

Type of machine -- lathe, mill, grinder, dual, ... USINT

Both

0

No

R

All Controls

11

NUM_OPTIONS

Num Options

UINT Max Value 2

Both

0

No

R

All Controls

3

NUM_PROCESSES

Num Proc

UINT Max Value 2

Both

0

No

R

All Controls

313

NUM_PROG_AXES

Number of programmable axes in the system

(incl duals)

UINT

Both

0

Yes

R

All Controls

314

NUM_PROG_AXES_PLUS_SKEWSLAVES

Number of prog axes plus deskew slaves in the

system

UINT

Both

0

Yes

R

All Controls

179

OEM_MESSAGE_1

OEM Message Line 1

STRING1

Both

0

No

R/W

All Controls

180

OEM_MESSAGE_2

OEM Message Line 2

STRING1

Both

0

No

R/W

All Controls

181

OEM_MESSAGE_3

OEM Message Line 3

STRING1

Both

0

No

R/W

All Controls

159

OPTION_SELECTED

Options Selected

USINT [ ]

Both

1

Num Options

No

R

All Controls

17

OPTION_SLOT_NAME_1

Option Slot Name - Slot 1

STRING1

OCI

0

No

R

All Controls

18

OPTION_SLOT_NAME_2

Option Slot Name - Slot 2

STRING1

OCI

0

No

R

All Controls

19

OPTION_SLOT_REV_1

Option Slot Revision - Slot 1

STRING1

OCI

0

No

R

All Controls

20

OPTION_SLOT_REV_2

Option Slot Revision - Slot 2

STRING1

OCI

0

No

R

All Controls

352

PROCESS_CHANGE_REQUEST

Assigning 1 forces process change for dual

INT

OCI

0

Yes

R/W

Dual

55

PROCESS_NAMES

Process Names

STRING1

OCI

0

Yes

R

Dual

12

PRODUCT_ID

Product ID

UINT enumerated

Both

0

No

R

All Controls

16

SERVO_FW_REVISION

Servo Firmware Revision

DINT [ ]

Both

1

Num Servo ModĆ

ules

No

R

All Controls

47

SYSTEM_STATE

System State

UINT enumerated

PAL

Both

0

Yes

R

All Controls

63

TIME

Current Time

STRING1

Both

0

No

R/W

All Controls

k

Offset Data

51

ACTIVE_TOOL_GEOM_NUM

Active Tool Geometry Number

UINT

Both

0

Yes

R

All Controls

350

ACTIVE_TOOL_LENGTH_AXIS_

LOGICAL_BIT_PATTERN

Bit pattern of axes currently programmed as

the active tool length axis

UDINT

Both

Yes

R

All Controls

53

ACTIVE_TOOL_RADIUS_NUM

Active Tool Radius Number

UINT

Both

0

Yes

R

All Controls

52

ACTIVE_TOOL_WEAR_NUM

Active Tool Wear Number

UINT

Both

0

Yes

R

All Controls

349

AMPED_TOOL_LENGTH_AXIS_

LOGICAL_BIT_PATTERN

Bit pattern of axes configured as tool length

axis

UDINT

Both

Yes

R

All Controls

39

D_WORD

D-Word for Display

UINT

Both

0

Yes

R

All Controls

351

DRILLING_AXIS_LOGICAL_BIT_PATTERN

Bit pattern of axes configured as drilling axis

for fixed cycles

UDINT

Both

Yes

R

All Controls

38

H_WORD

H-Word for Display

DINT

Both

0

Yes

R

All Controls