Rockwell Automation 8520-9API 9/Series OCI API Developer's Guide User Manual

Page 171

6–3

Array Indices and Strings

Publication 8520-6.6 - August 1999

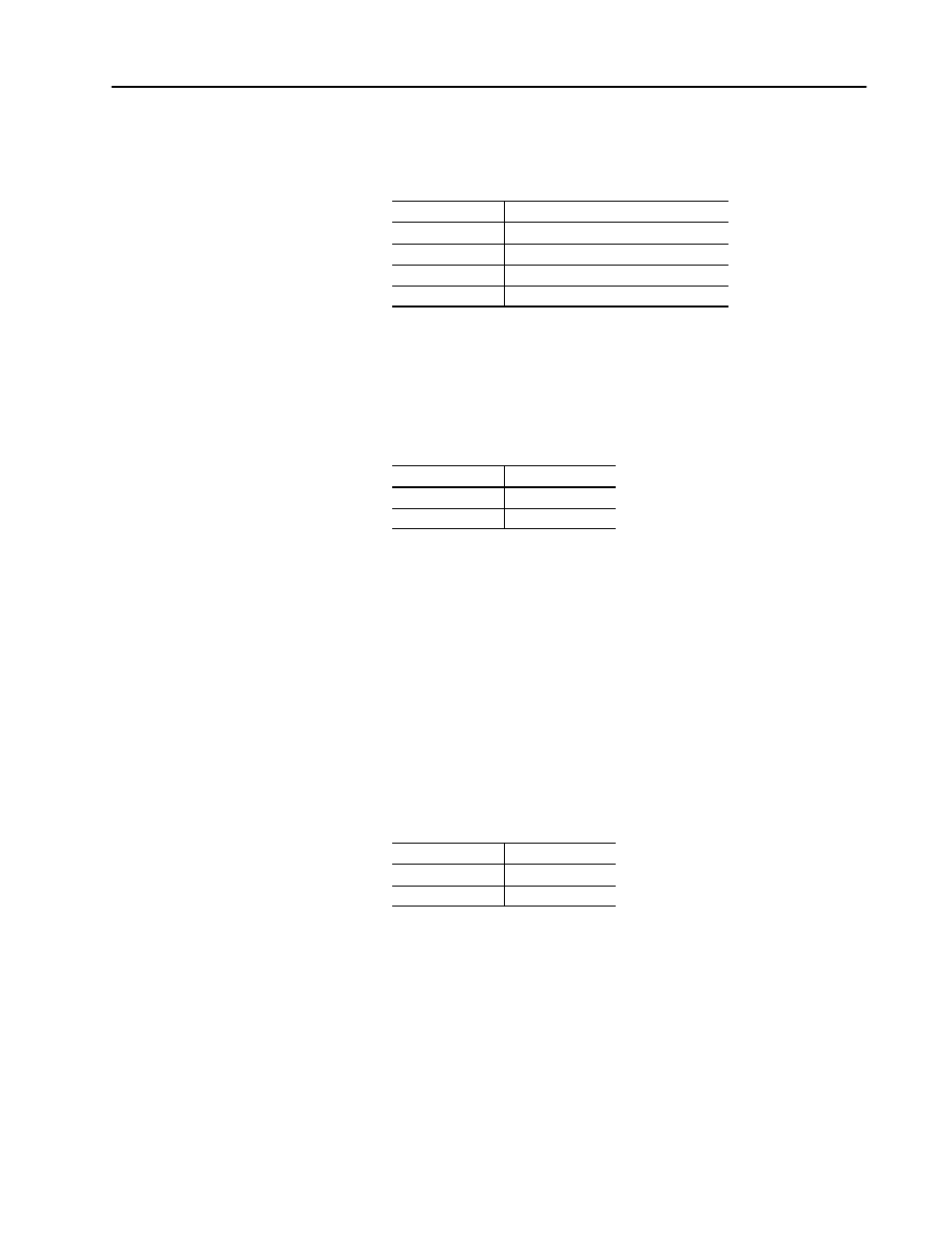

BACK_BORING_SHIFT_DIRECTION enumeration

This enumeration identifies the shift direction for back boring cycles.

Enumeration

Result:

+Axis 1 Name

Plane (G17/G18/G19) Primary Axis 1+

- Axis 1 Name

Plane (G17/G18/G19) Primary Axis 1-

+ Axis 2 Name

Plane (G17/G18/G19) Primary Axis 2+

-Axis 2 Name

Plane (G17/G18/G19) Primary Axis 2-

CALIBRATION_START enumeration

The Calibration Start enumeration is used to determine the start point

of axis calibration measurement for a specific axis. The

Calibration_Start enumeration is:

Enumeration

Result:

0

Most +

1

Most -

Most + means calibration points start at the calibration point entered

with the most positive value. Most negative means calibration points

start at the calibration point entered with the most negative value.

Subsequent points will then be measured from the most positive or

negative data point you enter for your ballscrew. The

Calibration_Type enumeration determines if the points are measured

from the start point or from subsequent entered points.

CALIBRATION_TYPE enumeration

The Calibration Type enumeration is used to identify the method

used to enter calibration data in the axis calibration tables for a

specific axis. The Calibration_Type enumeration is:

Enumeration

Result:

0

Measurement

1

Deviation

Measurement means each point entered is a measurement from the

original start point. Deviation means each point is a measurement

from the preceding adjacent point entered.