The oci data server – Rockwell Automation 8520-9API 9/Series OCI API Developer's Guide User Manual

Page 13

1–4

Open Control Interface (OCI) Overview

Publication 8520-6.6 - August 1999

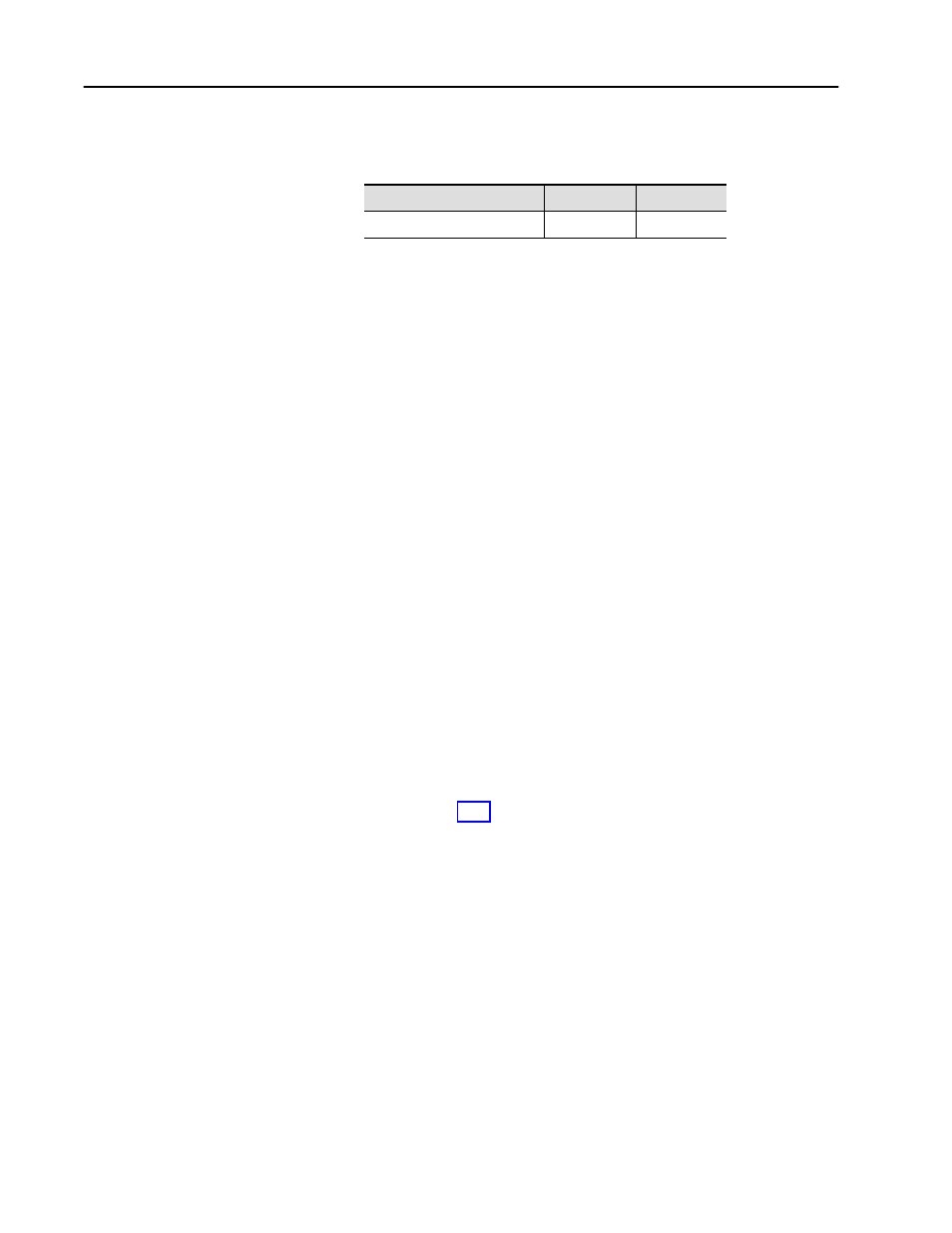

To access a piece of data named num_axes on a specific CNC, you

enter this information into your application’s DDE Link function:

Service (or Application) Name

Topic Name

Item Name

ABOCISERVER

CNC_1

NUM_AXES

Once you specify this information in your application program and

execute the request, the application establishes a link to the OCI data

server and requests the data or command.

Once installed and executing, the OCI data server is used to converse

between a 9/Series CNC (using RSLinx) or 9/PC CNC and your

application program (using DDE). Refer to your OCI Installation

Manual or 9/PC Installation and Integration Manual for details on

OCI installation and configuration.

The OCI data server provides a DDE interface for your application

program from a specific CNC. The service name for the OCI data

server is:

ABOCISERVER

The OCI data server runs in the Microsoft Windows NT

t

(4.0 or higher) operating environment.

OCI Data Server Read Data Requests

Your OCI application can request data from the CNC. Read requests

can be automatic or manual. Automatic items are added and

maintained on a watchlist at the control. Manual items are placed on

the watchlist just long enough to report the current value of the item.

Refer to page 4–1 for details on reading data items.

OCI Data Server Write Data Requests

Information can be written to your CNC using a Poke operation.

When a Poke request is made by your application program to the

OCI data server, the data server passes this data on to the CNC

processor which (if valid) will change the data item value.

The OCI Data Server