Rockwell Automation 2098-IPD-020-DN Ultra5000 Series Intelligent Positioning Drives with DeviceNet Reference Manual User Manual

Page 59

Publication 2098-RM002A-EN-P – October 2001

Programming Reference

4-35

136

Set

Motor Encoder

Interpolation

UINT

2

The amount of interpolation to be used with sine/

cosine encoders. For example, if the interpolation

is set to x256, the drive will interpolate 256

counts for every 1/4 line of the input sinusoid.

Valid values are:

4 = x4 (default)

8 = x8

16 = x16

32 = x32

64 = x64

128 = x128

256 = x256

512 = x512

1024 = x1024

137

Set

Motor Encoder

Polarity

USINT

1

Select the motor encoder's polarity.

0 = Positive (default) - Turning the motor in a

clockwise direction (as viewed from the shaft

end) increases the feedback position (in counts).

1 = Negative - turning the motor in a clockwise

direction (as viewed from the shaft end)

decreases the feedback position (in counts).

138

Set

Motor Encoder

Filter

USINT

1

Select the state of the motor encoder filer. The

filter reduces the upper limit of the rate at which

feedback pulses will be recognized. You may

need to enable feedback in a noisy environment,

or when a long encoder cable is used.

0 = Disable (default)

1 = Enable

139

Set

Master Encoder

Polarity

USINT

1

Select the master encoder's polarity.

0 = Positive (default) - Turning the motor in a

clockwise direction (as viewed from the shaft

end) increases the feedback position (in counts).

1 = Negative

140

Set

Master Encoder

Filter

USINT

1

Select the state of the master encoder filter. The

filter reduces the upper limit of the rate at which

feedback pulses will be recognized. You may

need to enable feedback in a noisy environment,

or when a long encoder cable is used.

0 = Disable (default)

1 = Enable

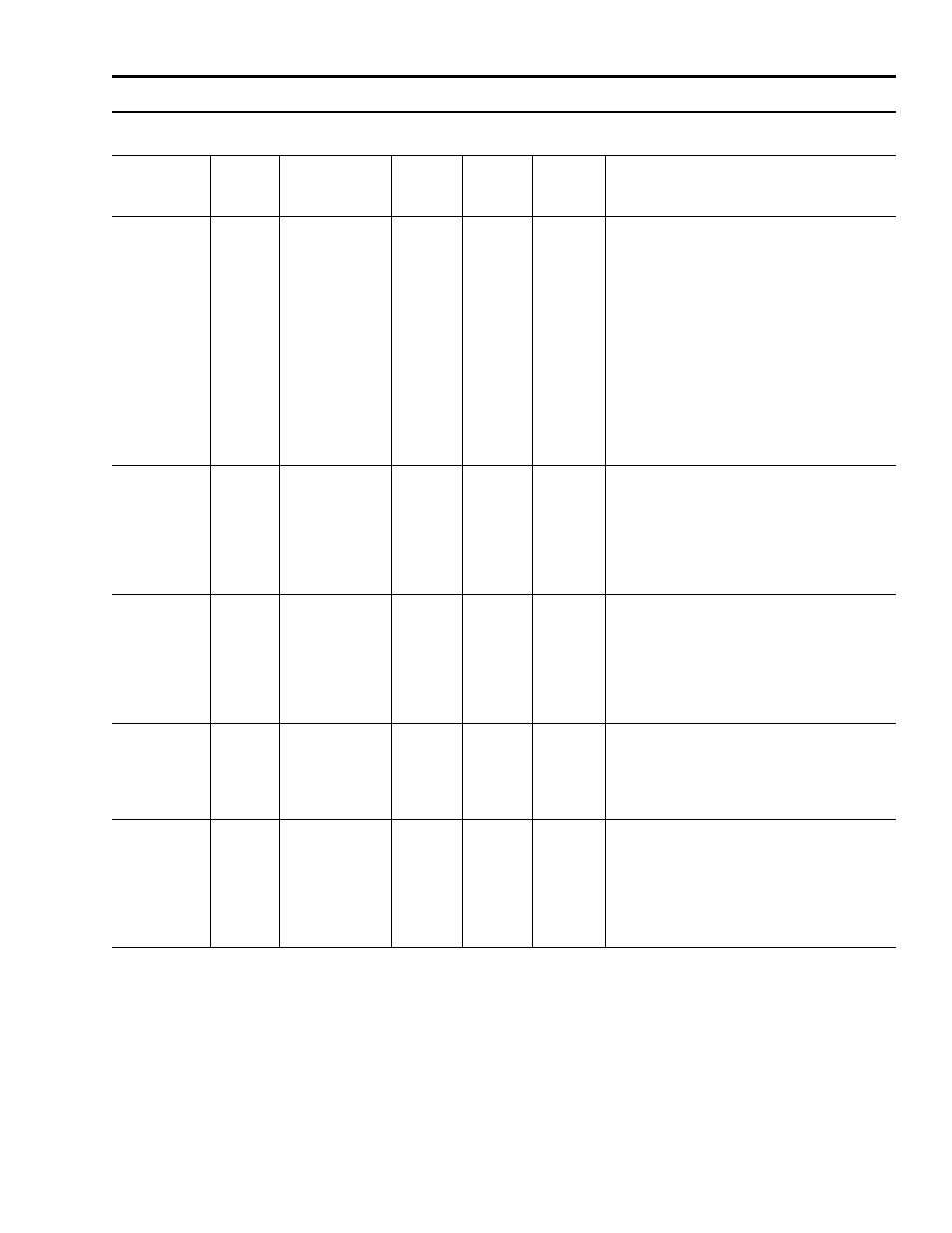

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Description