Rockwell Automation 2098-IPD-020-DN Ultra5000 Series Intelligent Positioning Drives with DeviceNet Reference Manual User Manual

Page 58

Publication 2098-RM002A-EN-P – October 2001

4-34

Programming Reference

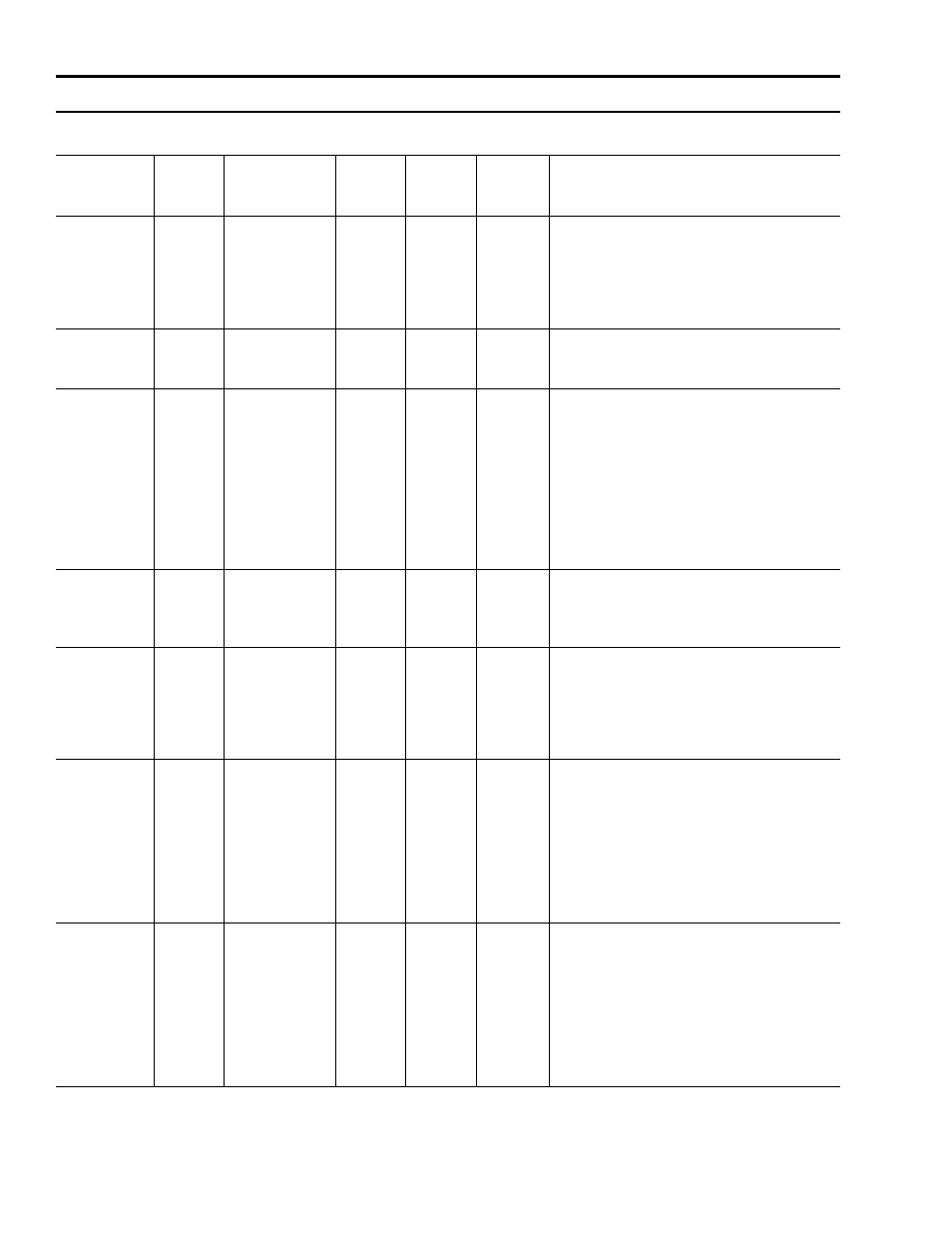

129

Set

Start Preg Tune

USINT

1

Drives the motor with a square (or step) wave, the

shape of which is determined by the commanded

Preg Tune Step, Preg Tune Period, and the

0 = No Action (default)

1 = Execute Command

130

Set

Stop Preg Tune

USINT

1

Stops position tuning.

0 = No Action (default)

1 = Execute Command

131

Set

Preg Tune

Direction

USINT

1

Selects a tuning direction. Not saved in

non-volatile memory.

0 = Bi-Directional (default) - to tune the drive

using an alternating step-input to create

alternately forward and reverse directional

motion.

1 = Forward Only - to tune the drive using a

step-input to create forward motion only.

2 = Reverse Only - Only to tune the drive using a

step-input to create reverse motion only.

132

Set

Preg Tune Period REAL

4

sec

The time the drive will hold its present step

position. Not saved in non-volatile memory.

Range: 0 to 3.4e10

Default: 0

133

Set

Preg Tune Step

DINT

4

cnts

The number of counts the drive will move in a

single direction. In Bi-Directional tuning, the

direction will alternate. Not saved in non-volatile

memory.

Range: 0 to 2147483647

Default: 0

134

Get

Preg Tune

Command

DINT

4

cnts

The position command driving the position

regulator while the position tuning algorithm is

running. If the Preg Tune Direction is set to c or

Reverse Only, this signal is adjusted after each

period of the tuning signal to remove the offset

that is accumulating in the position of the motor.

This allows the uni-directional signal to be

displayed in Ultraware's oscilloscope without

having to constantly adjust the offset.

135

Get

Preg Tune

Feedback

DINT

4

cnts

The position feedback to the position regulator

while the position tuning algorithm is running. If

the Preg Tune Direction is set to Forward Only or

Reverse Only, this signal is adjusted after each

period of the tuning signal to remove the offset

that is accumulating in the position of the motor.

This allows the uni-directional signal to be

displayed in Ultraware's oscilloscope without

having to constantly adjust the offset.

Parameter Object,

Instances ID 1- 340

Parameter

Instance

Access

Rule

Parameter

Name

Data

Type

Data

Size

(Bytes)

Units /

Scale

Description