Through-hole socket mount system (inmate) – Vicor Micro Family of DC-DC Converter User Manual

Page 79

Design Guide & Applications Manual

For Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Maxi, Mini, Micro Design Guide

Rev 4.9

vicorpower.com

Page 78 of 88

Apps. Eng. 800 927.9474

800 735.6200

16. Through-hole Socket Mount System (InMate)

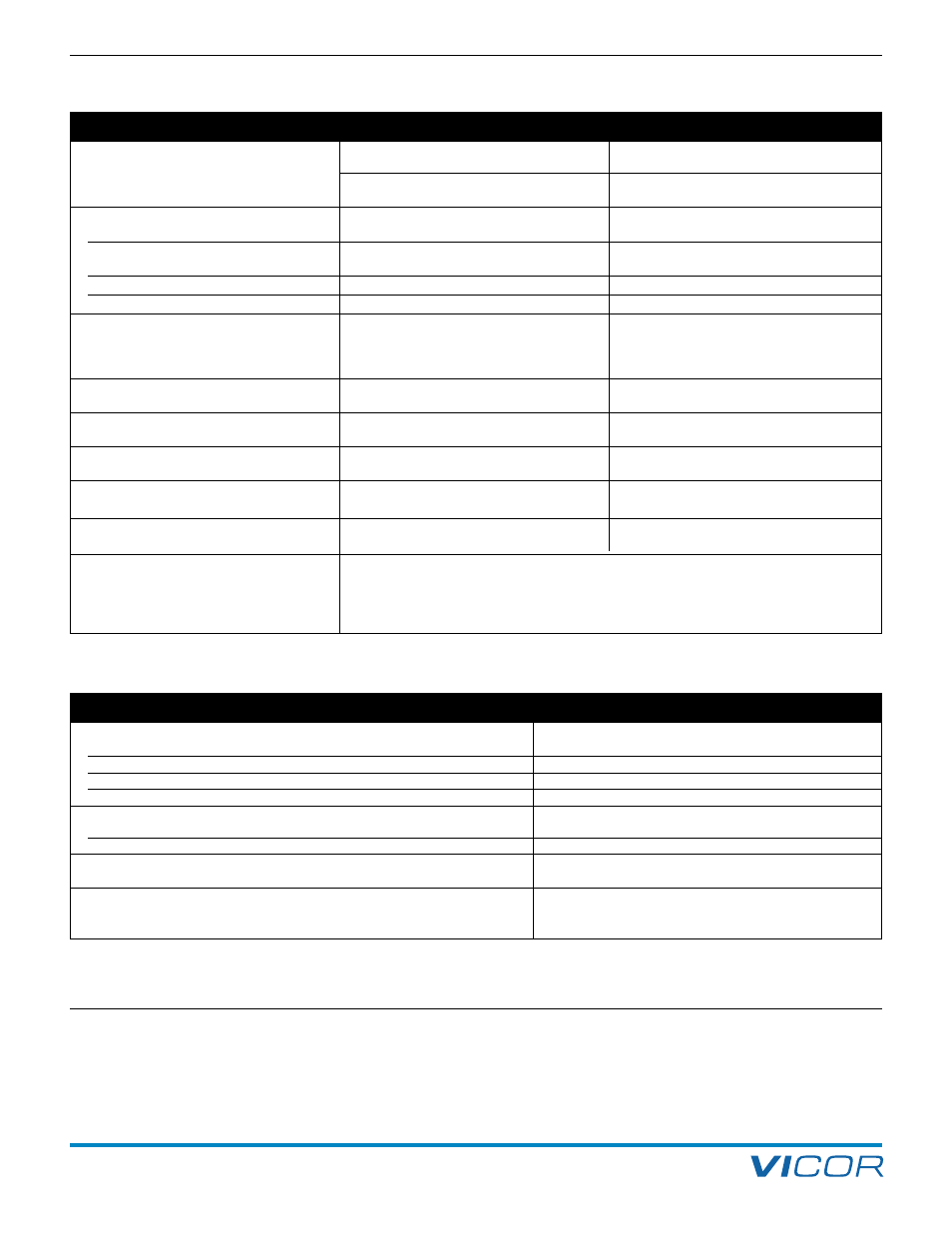

Table 16–2 — InMate specifications and materials

Table 16–3 — Material properties of InMate components

Parameter

Specification Value

Reference

Compatibility

F = short Au plated

Short RoHS pins

Module pin styles

S = short Au plated

Short ModuMate pins

G = long Au plated

Long RoHS pins

N = long Au plated

Long ModuMate pins

Mechanical

Contact normal force

100 grams EOL min.

GR-1217-CORE, R5-23

Number of mating cycles

5 max.

(Note4)

Exception to GR-1217-CORE

which specifies 25 mating cycle

Module engagement force

32 lbs per connector max.

GR-1217-CORE, R5-31,32

Module disengagement force

32 lbs per connector max.

GR-1217-CORE, R5-31,32

Electrical

Current rating for output pin sockets

50 A Maxi

(Note1)

/ 50 A Mini / 25 A Micro

Gold plating standards, and

(Based on 248°F (120°C) max socket temp. &

accepted industry standards

86°F (30°C) max temperature rise of contact)

such as IICIT, EIA, Bellcore guidelines

Low level contact resistance

0.080" (2,03 mm) dia socket (LLCR)

400 µ

Ω max.

GR-1217-CORE, 6.2.1

Low level contact resistance

0.150" (3,81 mm) dia socket (LLCR)

300 µ

Ω max.

GR-1217-CORE, 6.2.1

Low level contact resistance

0.180" (4,57 mm) dia sockets (LLCR)

200 µ

Ω max.

GR-1217-CORE, 6.2.1

Thermal

Max continuous use

Max socket temperature

248°F (120°C) max.

temperature for gold plating

Temperature rise

86°F (30°C) max.

GR-1217-CORE

(Note3)

EIA-364-70A

(Note2)

Environmental

InMate products are tested in random vibration environments to best simulate the broad spectrum

Shock and vibration

of frequencies and amplitudes that may be encountered in typical applications. Actual system

resonant frequencies will depend on PCB construction and mounting details.

For critical, or unusual, shock and vibration environments, the performance of the system should

be independently verified.

Materials

Ratings

Headers

Material: Ryton

TM

R–7 PPS, 65% glass fiber and mineral filled compound

Poly-Phenylene Sulfide

Flammability

UL94 V-0/5VA

Thermal stability (short term)

500°F (260°C)

Thermal stability (long term)

392°F (200°C)

Solder Cap

Material

305 stainless steel

Plating

Clear passivate to repel solder

Sockets

Brush Wellman Alloy #25

Material

C17200 deep draw quality or equiv. 0.010" thick

Plating

Woods nickel strike followed by 50 µ in. min. low stress

sulfamate-based electrolytic nickel, followed by

20 µ in min hard gold followed by 10 µ in. min. soft gold

(Note1)

For 80 A operation with Maxi, contact Applications Engineering.

(Note2)

GR-1217-CORE issue 1, November 1995 Generic requirements for

separable electrical connectors used in telecommunications

hardware. A module of NEBSFR, FR-2063

(Note3)

ANSI/EIA-364 American National Standards Institute / Electronic

Industries Association (Electronic Components, Assemblies &

Materials Association)

(Note4)

The module and socket must be replaced after 5 mating cycles.

(1)

For 80 A operation with Maxi, contact Applications Engineering.