Output ripple attenuator module (microram) – Vicor Micro Family of DC-DC Converter User Manual

Page 58

Design Guide & Applications Manual

For Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Maxi, Mini, Micro Design Guide

Rev 4.9

vicorpower.com

Page 57 of 88

Apps. Eng. 800 927.9474

800 735.6200

12. Output Ripple Attenuator Module (MicroRAM)

The SC or trim-up function can be used when remote

sensing is not available on the source converter or is not

desirable. It is specifically designed for converters with a

1.23 V reference and a 1 k

Ω input impedance like Vicor

Maxi, Mini, Micro converters. In comparison to remote

sensing, the SC configuration will have an error in the

load voltage versus load current. It will be proportional to

the output current and the resistance of the load path

from the output of the MicroRAM to the load.

The ORing feature prevents current flowing from the

output of the MicroRAM back through its input terminal

in a redundant system configuration in the event that a

converter output fails. When the converter output

supplying the MicroRAM droops below the ORed output

voltage potential of the redundant system, the input of

the MicroRAM is isolated from it’s output. Less than

50 mA will flow out of the input terminal of the MicroRAM

over the full range of input voltage under this condition.

Load capacitance can affect the overall phase margin of

the MicroRAM active loop as well as the phase margin

of the converter loop. The distributed variables such as

inductance of the load path, the capacitor type and

value as well as its ESR and ESL also affect transient capa-

bility at the load. The following guidelines should

be considered when point-of-load capacitance is used

with the MicroRAM in order to maintain a minimum of

30 degrees of phase margin.

1. Using ceramic load capacitance with <1 m

Ω

ESR and <1 nH ESL:

a. 20 µF to 200 µF requires 20 nH of trace / wire

load path inductance

b. 200 µF to 1,000 µF requires 60 nH of trace / wire

load path inductance

2. For the case where load capacitance is connected

directly to the output of the MicroRAM, i.e. no trace

inductance, and the ESR is >1 m

Ω:

a. 20 µF to 200 µF load capacitance needs an ESL

of >50 nH

b. 200 µF to 1,000 µF load capacitance needs an

ESL of >5 nH

3. Adding low ESR capacitance directly at the output

terminals of MicroRAM is not recommended and may

cause stability problems.

4. In practice, the distributed board or wire inductance

at a load or on a load board will be sufficient to

isolate the output of the MicroRAM from any load

capacitance and minimize any appreciable effect on

phase margin.

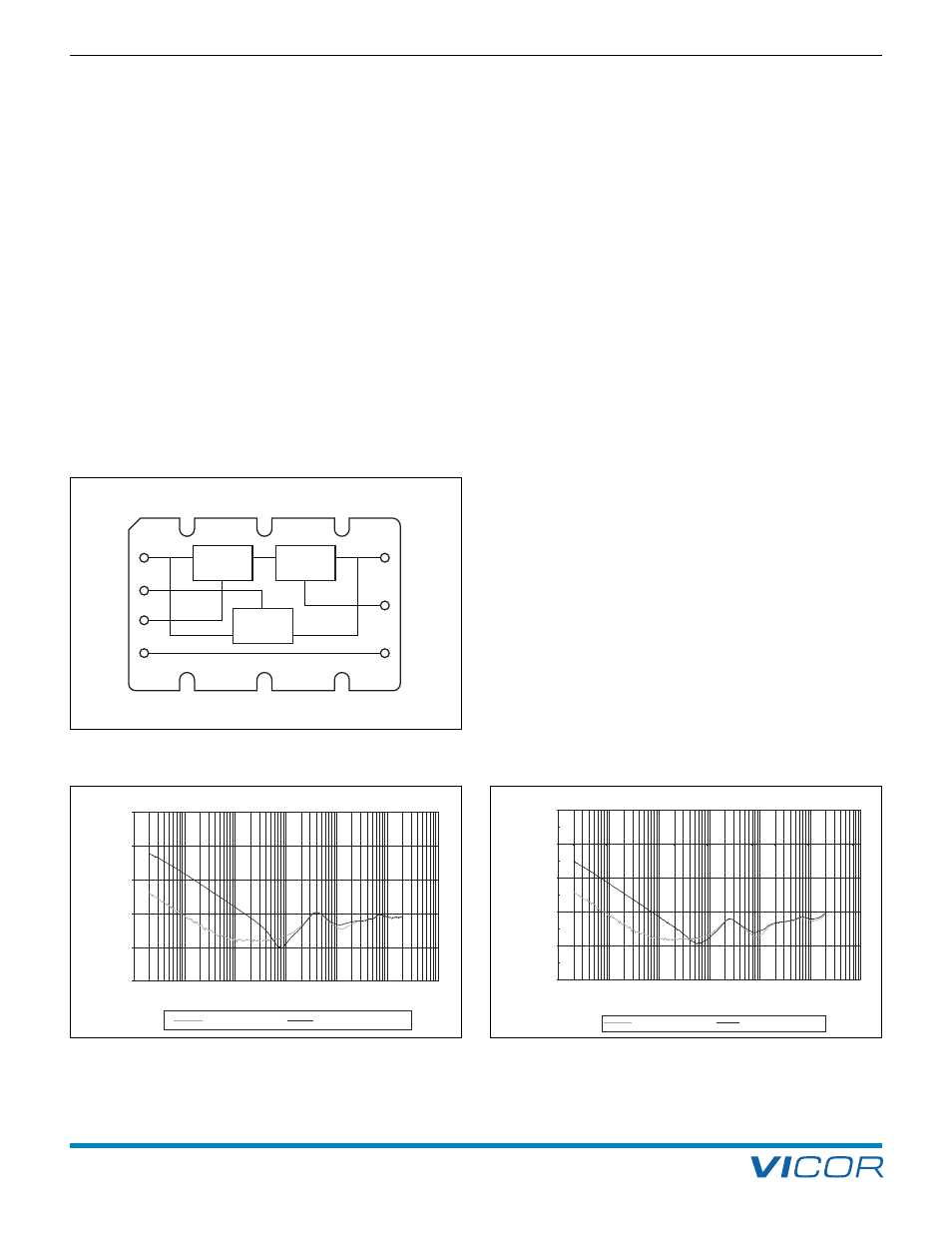

+Out

Vref

–Out

+In

SC

C

TRAN

–In

Passive

Block

Active

Block

SC

Control

Figure 12-2 — MicroRAM block diagram

Ripple Attenuation @ 28 V (Room Temp.)

-80.00

-60.00

-40.00

-20.00

0.00

20.00

10

100

1,000

10,000

100,000

1,000,000 10,000,000

Freq. (Hz)

G

a

in

(

d

B

)

10 A, 100 uF Vref

10 A, No Vref Cap

Figure 12–3a — The small signal attenuation performance as

measured on a network analyzer with a typical module at 28 V and

10 A output. The low frequency attenuation can be enhanced by

connecting a 100 µF capacitor, C

HR

, to the V

REF

pin as shown in

Figures 12–1 and 12–2.

Ripple Attenuation @ 5 V (Room Temp.)

-80.00

-60.00

-40.00

-20.00

0.00

20.00

10

100

1,000

10,000

100,000

1,000,000

10,000,000

Freq. (Hz)

G

a

in

(

d

B

)

10 A, 100 uF Vref

10 A, No Vref Cap

Figure 12–3b — The small signal attenuation performance as

measured on a network analyzer with a typical module at 5 V and

10 A. The low frequency attenuation can be enhanced by connect-

ing a 100 µF capacitor, C

HR

, to the V

REF

pin as shown in Figures

12–1 and 12–2.