Design requirements – Vicor Micro Family of DC-DC Converter User Manual

Page 17

Design Guide & Applications Manual

For Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Maxi, Mini, Micro Design Guide

Rev 4.9

vicorpower.com

Page 16 of 88

Apps. Eng. 800 927.9474

800 735.6200

3. Design Requirements

MAXIMUM OUTPUT CAPACITANCE

In general, adding external capacitance to the Maxi, Mini,

and Micro’s output is not required. However, it is often

common practice with power supply designs to add external

capacitance to the converter output for attenuation of

output ripple and / or improving dynamic load performance.

The Maxi, Mini, Micro converters typically have a faster

response to dynamic loads than other power solutions;

hence, external capacitors may not be necessary. In addition,

the output ripple and noise specification listed on the data

sheet may be acceptable for many applications.

A general equation for determining the maximum recom-

mended output capacitance is as follows:

P

out

(400x10

-6

)

C

(farad)

=

V

out

V

out

where: P

out

is the output power of the converter

V

out

is the nominal output voltage of the converter

The capacitance value is not the absolute maximum value,

but the value for which general application of the converter

can be deemed appropriate. Testing will be required to

ensure that the module is stable if this value is exceeded.

Approximately 10X the value calculated will cause the

converter to go into current limit at turn-on.

CAUTION: If exceeding this value, it is recommended

that Vicor Applications Engineering be consulted.

ABSOLUTE MAXIMUM RATINGS

Please consult the latest module data sheets available on

the Vicor website for maximum ratings concerning pin-to-

pin voltages, isolation, temperature, and mechanical ratings.

GROUNDING OF BASEPLATE AND REFERENCING

OF INPUT AND OUTPUT TERMINALS

The baseplate of the converter should always be connected

to earth ground. If for any reason this is not possible in

your application please consult with Vicor Applications

Engineering for acceptable alternatives for your application.

The input and output leads of the converter should be

referenced to the baseplate at some point to avoid stray

voltages. For offline applications the input leads are often

referenced to earth ground at the AC source ahead of the

bridge rectifier. Either + or –Output terminal may be

referenced to earth ground and the baseplate. “Floating”

inputs or outputs should at a minimum have a high-

resistance divider to bleed off stray charges to avoid

damage to the insulation system.

HIGH FREQUENCY BYPASSING

All Vicor converters must be bypassed for proper operation.

(Figure 3–2) The minimum complement of high-frequency

bypass capacitors must consist of the following:

•

0.2 µF ceramic or film type connected between

+In and –In.

•

4.7 nF Y-capacitor between +In and baseplate

and –In and baseplate.

•

10 nF ceramic or film capacitor between +Out and

baseplate and –Out and baseplate.

All applications utilizing Maxi, Mini, Micro converters

should be properly bypassed, even if no EMC standards

need to be met. Bypass Vin and Vout pins to each module

baseplate as shown in Figure 3–2. Lead length should

be as short as possible. Recommended values vary

depending on the front end, if any, that is used with the

modules, and are indicated on the appropriate data sheet

or application note. In most applications, C1 is a 4,700 pF

Y-capacitor (Vicor P/N 01000) carrying the appropriate

safety agency approval; C2 is a 4,700 pF Y-capacitor (Vicor

P/N 01000) or a 0.01 µF ceramic capacitor rated at 500 V.

In PC board applications, each of these components is

typically small enough to fit under the module baseplate

flange. For PCB mounting of the module. Please refer to

Figures 3–3 and 3–4.

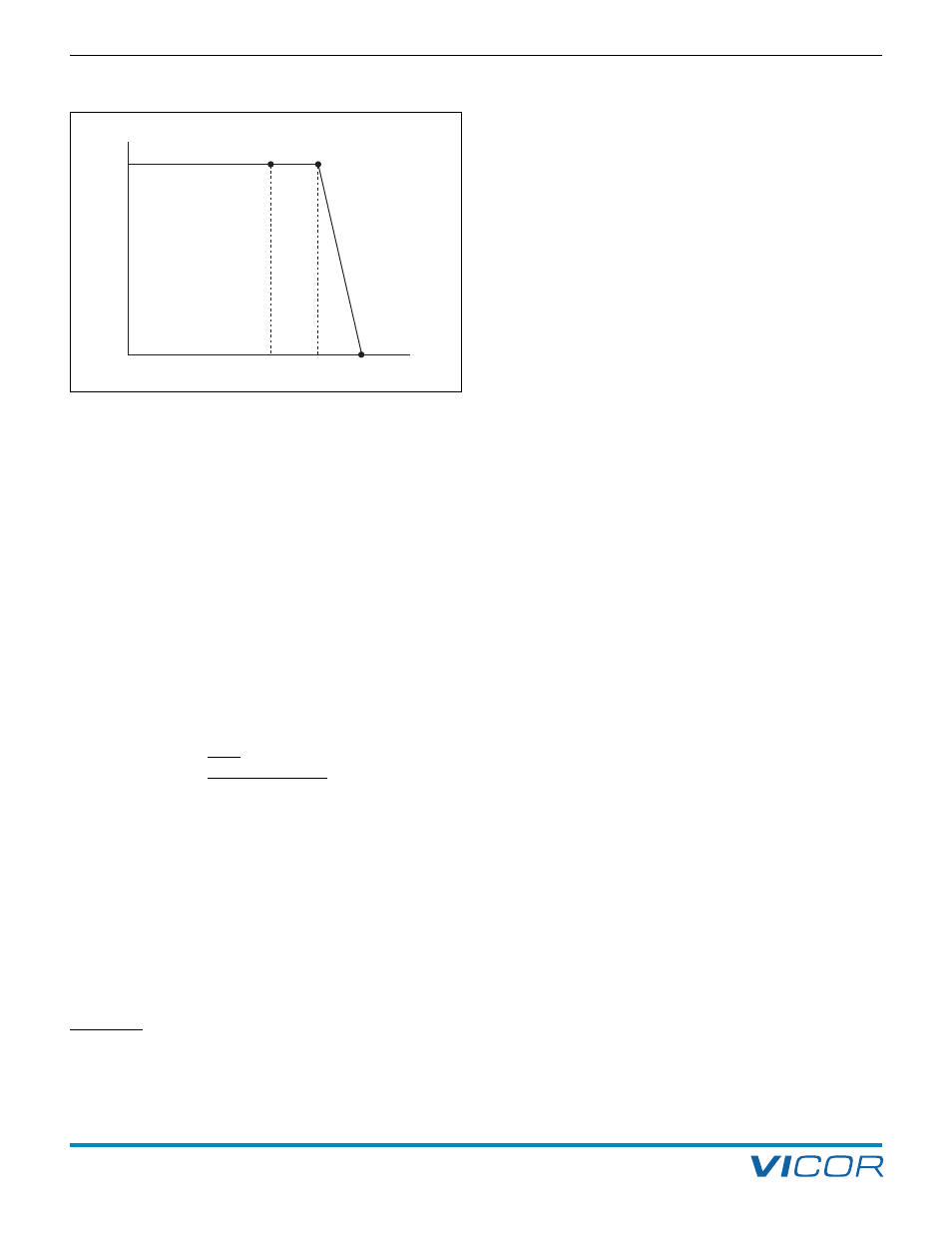

Vout

I

KNEE

I

MAX

I

SHORT CIRCUIT

Iout

Figure 3–1 — Typical Maxi, Mini, Micro current limiting