High density dc-dc converter technology, 7,3 w/cm – Vicor Micro Family of DC-DC Converter User Manual

Page 3

Design Guide & Applications Manual

For Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Maxi, Mini, Micro Design Guide

Rev 4.9

vicorpower.com

Page 2 of 88

Apps. Eng. 800 927.9474

800 735.6200

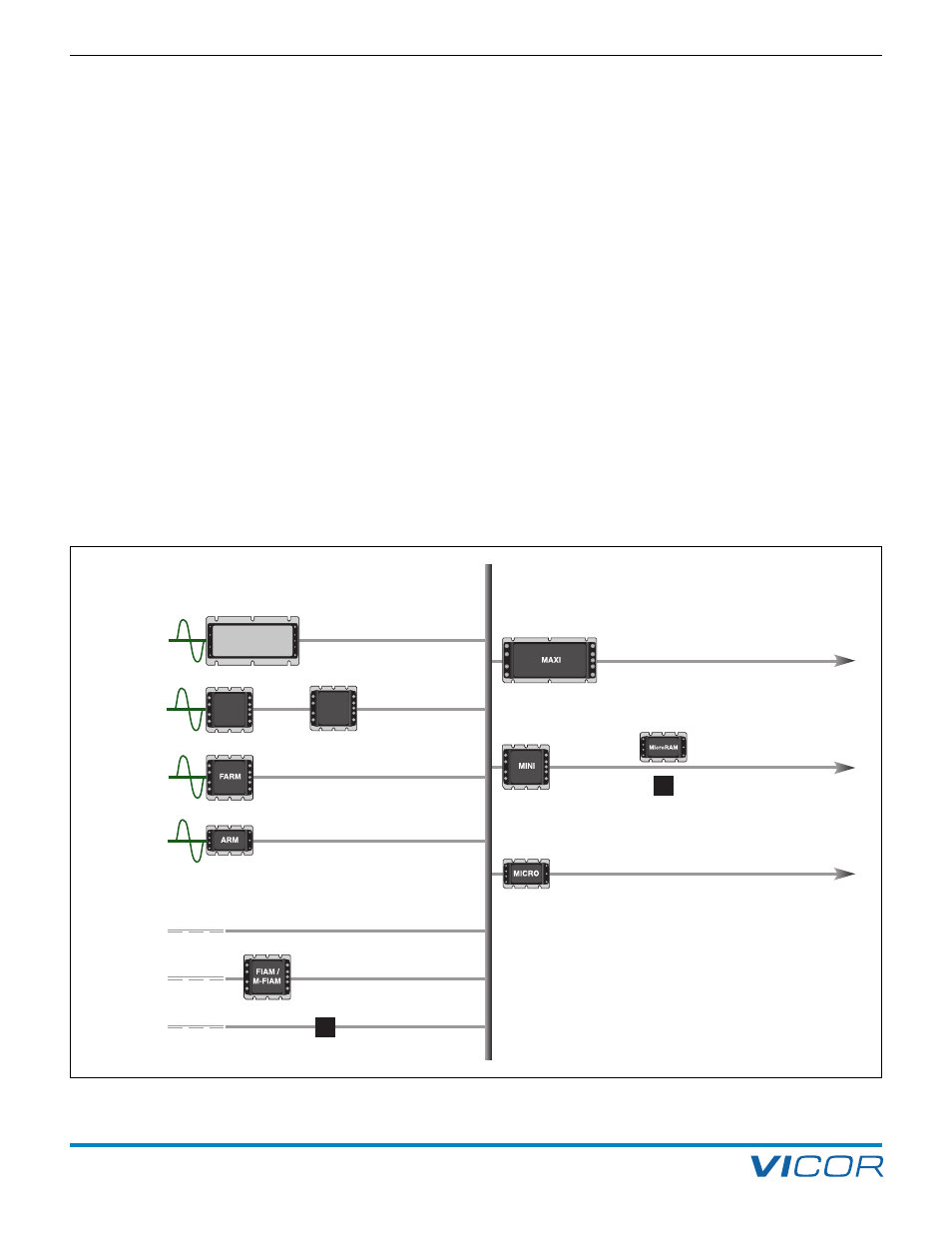

1. High Density DC-DC Converter Technology

AC-DC Products

DC-DC Products

Universal

85 – 264 Vac

Autoranging

90 – 132 Vac

180 – 264 Vac

Autoranging

90 – 132 Vac

180 – 264 Vac

Autoranging

115 – 230 Vac

Input

Nominal Input

18 – 425 Vdc

28 Vdc, 48 Vdc,

270 Vdc

24 Vdc, 28 Vdc,

48 Vdc

Harmonic Attenuator Module

Unity Power Factor

Up to 675 W

per module

Filter / Autoranging Rectifier Module

Up to 1,000 W

Autoranging Rectifier Module

Up to 1,500 W

Front-end System

for EN Compliance

Up to 550 W

Transient Protection,

Inrush Current Limiting EMI Filter

Up to 25 A

Active EMI Filter

Up to 576 W @ 48 V

DC-DC Converter

Up to 600 W per module

1 – 54 Vdc

MINIHAM

FARM3

QPI

DC-DC Converter

Up to 300 W per module

1 – 48 Vdc

DC-DC Converter

Up to 150 W per module

1 – 48 Vdc

Single wire paralleling for

high power, fault tolerant arrays.

Output Ripple Attenuation Module

combines active and passive filtering.

QPO provides active filtering to

achieve differential noise attenuation.

QPO

DC-DC Products

High Boost

HAM

The Maxi, Mini, Micro Family of DC-DC converters are an

integral part of the company’s overall component power

solution strategy, (Figure 1–1), which includes advanced

factory and design automation. The modules are available

in an unlimited variety of standard versions, to the extent

that the line between custom and standard DC-DC

converter bricks becomes almost indistinguishable.

The design of the control, magnetic, switching, and

packaging elements of the module resulted in a

component with a power density of up to 120 W/in

3

(7,3 W/cm

3

) in three package sizes:

Maxi 4.6" x 2.2" x 0.5" (117 x 55,9 x 12,7 mm)

Mini 2.28" x 2.2" x 0.5"(57,9 x 55,9 x 12,7 mm)

Micro 2.28" x 1.45" x 0.5"(57,9 x 36,8 x 12,7 mm)

The modules have one-third the number of parts of their

predecessors.

While the natural by-products of this reduction in parts

count has improved reliability and lower cost, the extra

space also means that the bulk of the converter can now

be devoted almost exclusively to the power train (i.e., the

magnetic and switching elements at the core of the design).

Resistors can be used to trim the output voltage up or

down, if necessary. Six pin styles, three baseplate options,

and a variety of data collection and reporting options are

available. The devices have an operating temperature

range of –55°C to 100°C and come in five product

grades – E, C, T, H, and M.

Other specifications include a typical no-load to full-load

regulation of ±0.5%, a programmable output of 10% to

110%, conversion efficiencies of up to 92% depending

on the voltage combination and power level chosen, and

an input-to-output isolation test voltage of 3,000 Vrms

(4,242 Vdc). All models are parallelable with N+M fault

tolerance and current sharing. Paralleling architectures

feature DC or AC-coupled interface.

Figure 1–1 — Component power solutions with the Maxi, Mini, Micro Family