High density dc-dc converter technology – Vicor Micro Family of DC-DC Converter User Manual

Page 4

Design Guide & Applications Manual

For Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Maxi, Mini, Micro Design Guide

Rev 4.9

vicorpower.com

Page 3 of 88

Apps. Eng. 800 927.9474

800 735.6200

1. High Density DC-DC Converter Technology

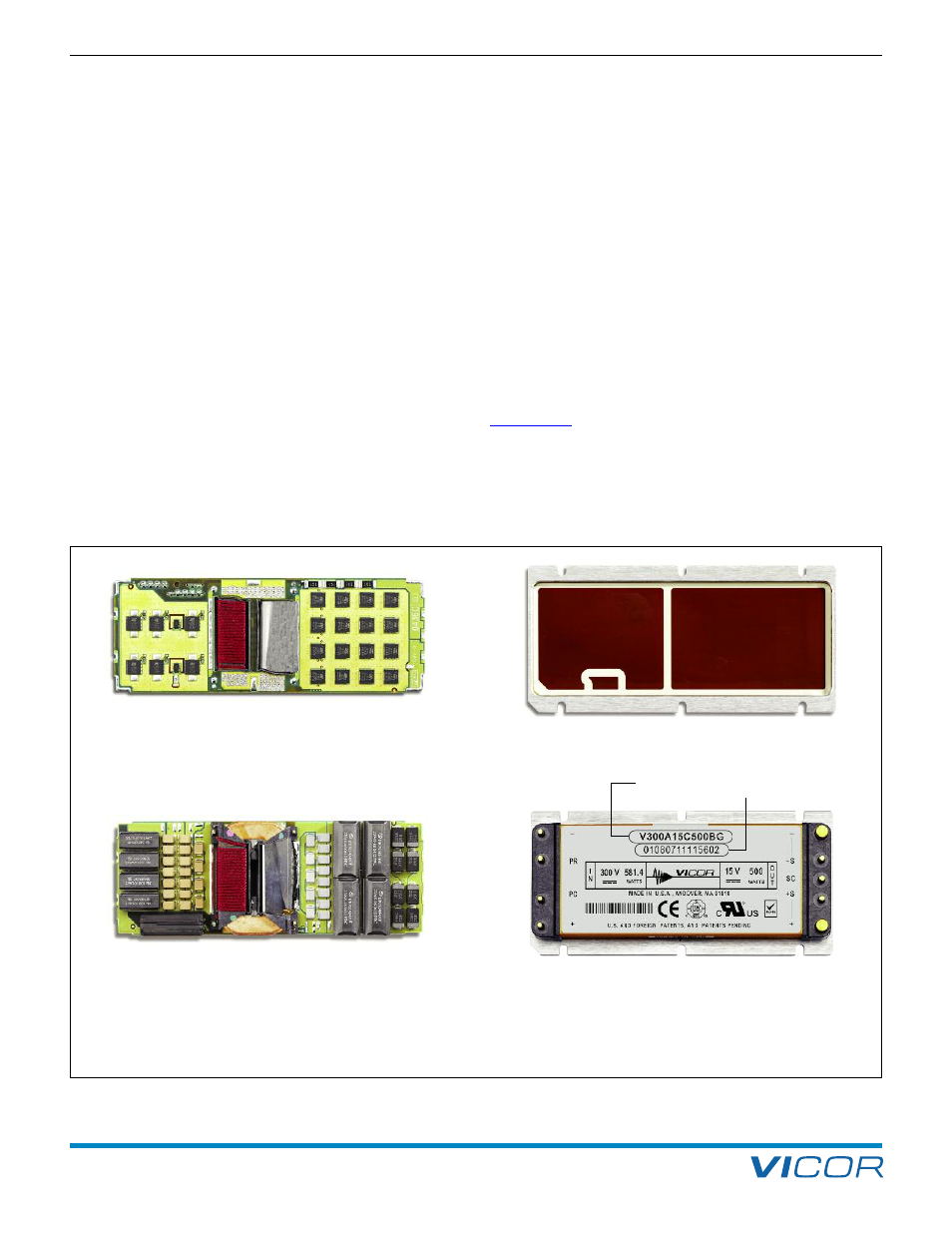

Key to the design of Maxi, Mini, Micro converters is its

high level of component-level integration. (Figure 1–2)

With the aid of hybrid technology, the device packs all

control functions and active circuitry into two (primary

and secondary side) ICs occupying a total volume of less

than 1/10 in

3

(1,6 cm

3

) each.

With Maxi, Mini, Micro devices, the plated-cavity trans-

former cores use copper armor, plated onto the ferrite

core, to more closely confine the magnetic flux to couple

widely separated primary and secondary windings. The

wider separation provides greater isolation and therefore

lowers input-to-output parasitic capacitance and noise.

The plated cavity also serves to conduct heat away from

the transformer to the baseplate, thus increasing the

power-handling capability of the power train and minimiz-

ing temperature rise.

The power-train assembly is contained between the

baseplate and a terminal-block assembly, with input and

output pins recessed. This allows the converter body to be

mounted into an aperture in the PCB to reduce the height

above board. The modules may be wave soldered or

plugged into through-hole or surface-mount sockets.

The Maxi, Mini, Micro devices use a proprietary, low-noise,

integrated power device that has an order of magnitude

lower parasitic effect.

The advances made in the overall design of the Maxi,

Mini, Micro Family DC-DC converters have been comple-

mented by equally significant advances in the technology

used to manufacture them. Vicor invested in a custom,

fully-automated assembly line specifically designed for the

assembly of Maxi, Mini, Micro power components. To

further augment its Maxi, Mini, Micro product offering,

Vicor has created an online user-interface tool,

M

, that allows customers to specify DC-DC

module requirements anytime, anywhere via the internet.

Bottom View

• Standard MLP power devices

• Efficient pick-and-place assembly

Top View

• Surface mount components for greater

manufacturing efficiency

• Standard reflow process

Baseplate

• Simplified baseplate construction

Complete Assembly

• Insert molded terminal block for more

accurate pin positioning

• One piece cover with label

• Encapsulated for superior thermal performance

Figure 1–2 — Maxi assembly shows high level of integration.

Model Number

Serial No. & Date Code