Non-spinning applications (laboratory), Non-spinning applications (laboratory) 17 – MTS SWIFT 10 MC Sensor User Manual

Page 17

Non-Spinning Applications (Laboratory)

SWIFT 10 MC Sensors

Hardware Overview

17

Non-Spinning Applications (Laboratory)

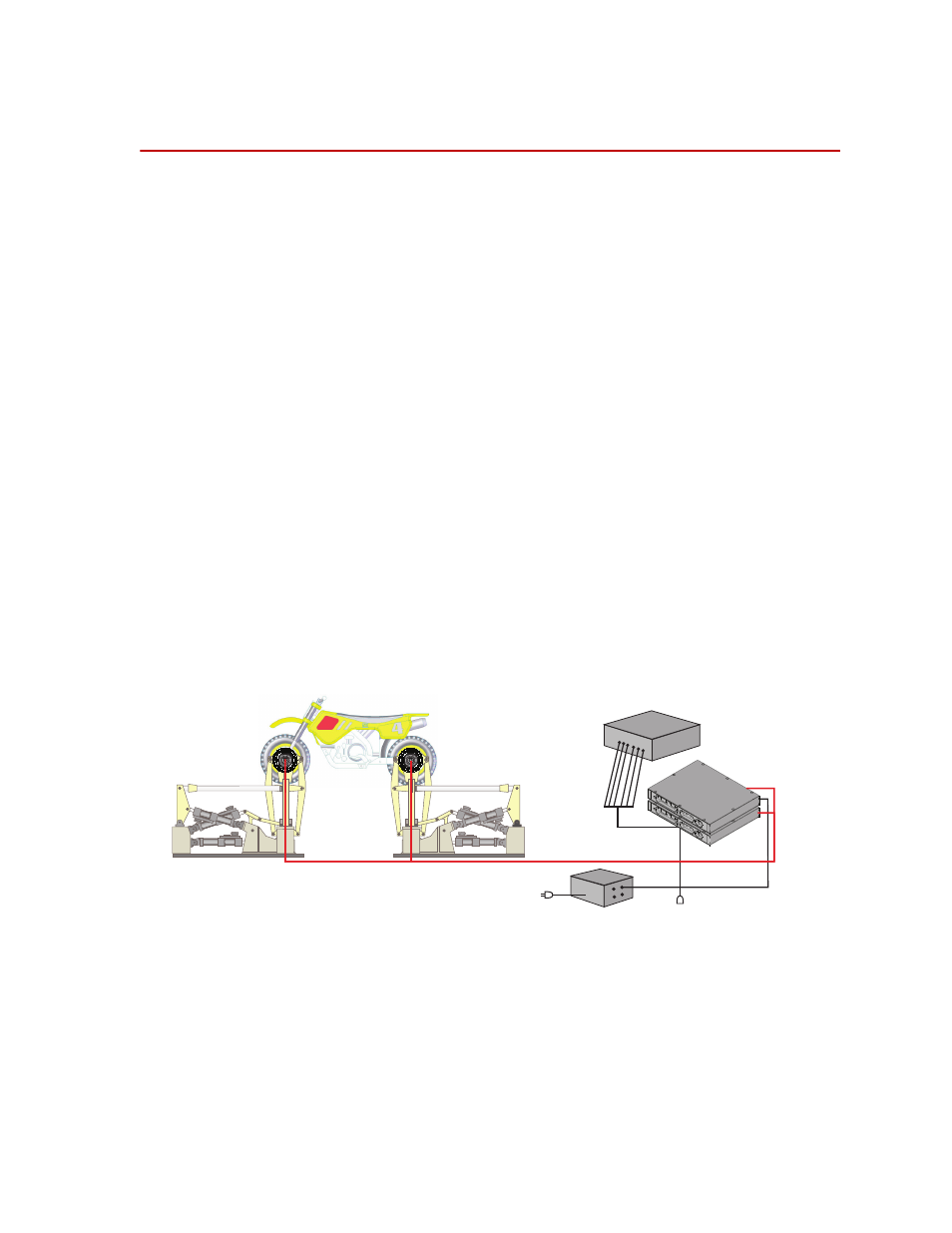

The SWIFT sensor can be fully integrated into the simulation process, since it is

an optimal feedback transducer for use with MTS Remote Parameter Control

®

(RPC

®

) software. The transducer takes data at points where fixturing inputs are

located rather than at traditional instrumentation points along the vehicle’s

suspension. Using the SWIFT sensor saves you instrumentation time, and fewer

iterations are required to achieve good simulation accuracy.

Measuring spindle loads allows engineers to generate generic road profiles.

Generic road profiles are portable across various vehicle models, do not require

new test track load measurements for each vehicle, and eliminate additional

RLDA tasks.

Several of the six loads measured by the transducer directly correlate to the MTS

Model 329 Road Simulator inputs.

The same transducers used to collect road data can be mounted directly in the

wheel adapters of the MTS Model 329 Road Simulator. For durability testing, the

SWIFT sensor can be used for iterations within the RPC process. The SWIFT

sensor should then be removed for the durability cycles, to preserve its fatigue

life. It can be replaced by an adapter plate, available from MTS, to duplicate the

mass and center of gravity of the actual SWIFT sensor. If a SWIFT sensor is to be

used during full durability tests, we suggest using the titanium model, which has

a higher fatigue rating.

In a typical non-spinning application, a SWIFT sensor is mounted on a road

simulation test fixture, as shown in the following figure.

Non-Spinning Application (Laboratory Simulation)

Power Supply (with 4

connections)

Customer-Supplied

Test Control System

Transducer

Interface (TI)

Transducer Signals

Output

Signals

PC Communication

S10MC-03