MTS SWIFT 10 MC Sensor User Manual

Page 128

THE INFORMATION AND DESIGN(S)

DISCLOSED HEREIN ARE CONFIDENTIAL

AND THE PROPERTY OF MTS SYSTEMS

CORPORATION AND MAY NOT BE USED,

REPRODUCED OR DISCLOSED IN ANY

FORM EXCEPT AS GRANTED IN WRITING

BY MTS SYSTEMS CORPORATION. THIS

RESTRICTION EXCLUDES INFORMATION

THAT IS IN THE PUBLIC DOMAIN OR

WAS LEGITIMATELY IN THE PRIOR

POSSESSION OF THE RECIPIENT.

PROPRIETARY DATA

SOURCE/REF

DRAWING

MATERIAL DESCRIPTION

MATERIAL SIZE

FINISH

MASK

M

THREAD DEPTHS ARE TO MIN FULL THDS

DRILL DEPTHS ARE TO FULL DIA

REMOVE BURRS AND SHARP EDGES

DO NOT SCALE PRINT

SCALE

MACHINED

SURFACES

180

UNLESS OTHERWISE SPECIFIED

.XXX HOLE SIZE TOLERANCE

0.000

TO .750

+.010/-.002

OVER .750

TO 1.500

+.015/-.003

ANGLE 2

G

E

N

E

R

A

L

T

OL

E

R

A

N

C

E

S

X

Y

.X

.XX

.XXX

THIRD

ANGLE

PROJ

C

MTS SYSTEMS CORPORATION

EDEN PRAIRIE, MINNESOTA U.S.A.

1/4

.1

.03

.010

DRAWN

CHECK

ENGR

DATE

MFG

DATE

DATE

DATE

SIZE

TITLE

NEXT LEVEL

PRODUCT CODE

NUMBER

SHEET

OF

REV

D

REVISIONS

DATE

ENGR

DRAWN

L

E

T

T

E

R

E

C

N

N

O

DESCRIPTION

m

NOTES (CONTINUED):

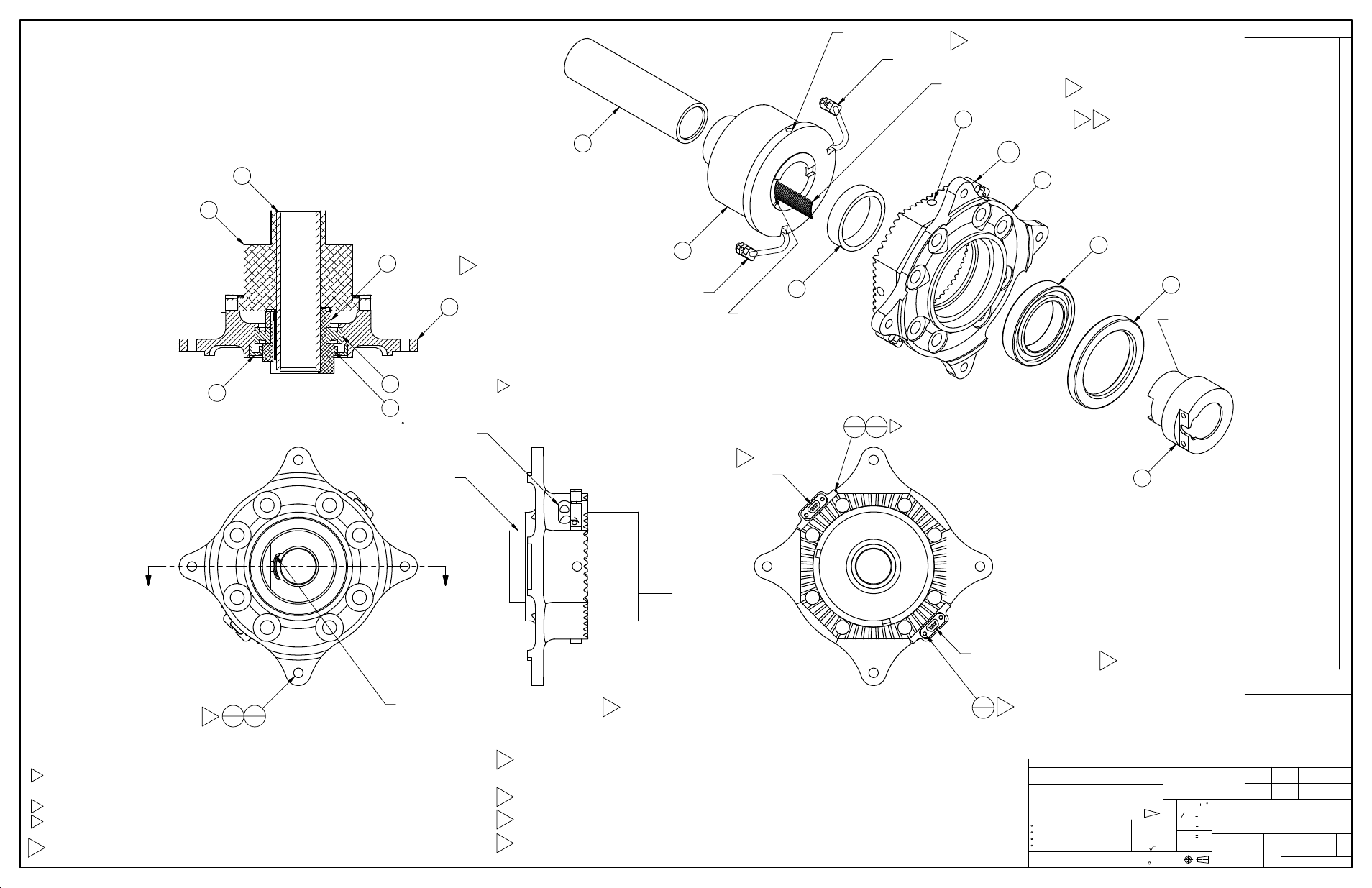

APPLY A SMALL AMOUNT OF OIL/LUBRICANT TO OUTER DIAMETER OF BEARING (ITEM 19) AND

PRESS IN TO INNER HUB (ITEM 5), UNTIL IT IS FULLY RESTED AGAINST SHOULDER AS SHOWN.

IT IS IMPORTANT THAT BEARING IS PRESSED IN ON THE OUTER RACE.

PRESS IN OIL SEAL (ITEM 20) INTO INNER HUB, UNTIL IT FULLY RESTS AGAINST SHOULDER.

ATTACH CONNECTOR BRACKETS (ITEM 18) TO INNER HUB. APPLY LOCTITE 222 THREADLOCKER

TO #4-40UNC SOCKET HEAD CAPSCREWS AND TORQUE TO 10 IN-LB.

PRESS AXLE SPACER (ITEM 12) INTO OIL SEAL, UNTIL IT FULLY RESTS AGAINST THE BALL BEARING.

THE LOAD SPACER (ITEM 9) SHOULD THEN BE PLACED OVER THE AXLE SPACER AS SHOWN.

ASSEMBLE SLIP RING/ENCODER ASSEMBLY (ITEM 8) TO INNER HUB (ITEM 5). WHILE ALIGNING PIN HOLE

IN OUTER FLANGE OF SLIP RING WITH THE SETSCREW HOLE ON INNER HUB AS SHOWN IN ISOMETRIC VIEW,

ROUTE BOTH 9-PIN CONNECTORS THRU SLOTS LOCATED ON THE INNER HUB. ALSO ROUTE SLIP RING LEAD

OUT WIRES THRU THE WIDE CHANNEL ON THE AXLE SPACER AS NOTED IN THE FRONT VIEW.

APPLY LOCTITE 262 THREADLOCKER TO SETSCREW (ITEM 24) AND FIRMLY TORQUE UNTIL FULLY SEATED.

ROUTE SLIP RING 9-PIN CONNECTOR CABLE THRU SLOT ON CONNECTOR BRACKETS (ITEM 18) AND SEAT

CONNECTORS DOWN INTO THE POCKETS IN BRACKETS. APPLY LOCTITE 222 THREADLOCKER TO #2-56UNC

FLAT HEAD SCREWS (ITEM 22) AND TORQUE TO 5 IN-LB.

ATTACH BRAKE DISC (ITEM 27) TO INNER HUB USING M8 X 1.25MM BUTTON HEAD CAPSCREWS (ITEM 26).

APPLY LOCTITE 262 THREADLOCKER AND TORQUE TO 18 FT-LB (24 N-M).

7

8

9

RLJ

RAM

7-07

7-07

3

5

100-180-624

RIM ASSEMBLY-FRONT,

21 X 1.60 RIM, SWIFT 10

C

18

2

21

4

5 CONDUCTOR, BOARD 2,

9-PIN SLIP RING CONNECTOR

(NOTE THE DIRECTION OF THE

DOVETAIL ON THE CONNECTOR SHELL)

6 CONDUCTOR, BOARD 1,

9-PIN SLIP RING CONNECTOR

(NOTE DIRECTION OF THE

DOVETAIL ON THE CONNECTOR SHELL)

22

4

9

C

C

10

11

12

13

ROUTE SLIP RING/ENCODER LEAD OUT WIRES

THRU WIDE CHANNEL ON AXLE SPACER (ITEM 12)

14

27

1

26

4

14

THRU SLOT (2 LOCATED 180 APART) FOR

ROUTING 9-PIN SLIP RING CONNECTORS (REF)

APPLY GREASE ON DIAMETER,

TO REDUCE FRICTION BETWEEN

AXLE SPACER AND OIL SEAL

11

13

8

10

18

2

19

20

12

AXLE SPACER KEY

SLIP RING KEYWAY

6 CONDUCTOR, BOARD 1,

9-PIN SLIP RING CONNECTOR

5 CONDUCTOR, BOARD 2,

9-PIN SLIP RING CONNECTOR

PIN HOLE FOR SETSCREW

(USE FOR ORIENTATION)

INNER HUB ASSEMBLY

(CONNECTOR SIDE)

(BRAKE DISC NOT SHOWN)

SQUARE HD, FULL DOG

POINT SETSCREW

SLIP RING LEAD OUT WIRES

TO SYSTEM CABLE ASSEMBLY

AXLE SLEEVE

SLIP RING/ENCODER

LOAD

SPACER

CONNECTOR BRACKET

SEALED BALL BEARING

OIL SEAL

AXLE SPACER

7

10

11

11

11

12

13

13

13

INNER HUB/

BRAKE DISC ADAPTER

4

INNER HUB/

BRAKE DISC ADAPTER

24

SECTION C-C

13

AXLE SLEEVE

8

SLIP RING/ENCODER

20

OIL SEAL

19 SEALED BALL BEARING

12 AXLE SPACER

4

10 LOAD SPACER