1 chopping frequency – Lenze 8615E User Manual

Page 93

91

6

Additional open-loop and closed-loop control

functions

6.1

Chopping frequency

The inverters of the 8600 series offer the feature to adapt the

chopping frequency of the inverter to the noise and smooth running

requirements of the motor. By increasing the chopping frequency

you can generally reduce the motor noises which are generated by

the pulsating output voltage.

By reducing the chopping frequency the smooth running in the low

frequency range is often improved. Under code C018 you can

select a variable or fixed chopping frequency.

Variable chopping frequency

With a chopping frequency, from 4 to 16 kHz variable, the set

chopping frequency is maintained as long as the switching losses in

the inverter allow for this. If an overload is recognized, the chopping

frequency is reduced automatically to the extent as it is necessary

to continue operation. If the motor current is reduced again, the

chopping frequency is increased.

Fixed chopping frequency

When a fixed chopping frequency is set, the chopping frequency is

not reduced in case of overload. A fixed chopping frequency is

useful only when the reduction of the motor noise is important in

every operating state or if motor noise filters are used. By reducing

the maximum current internally, the overload capacity is restricted.

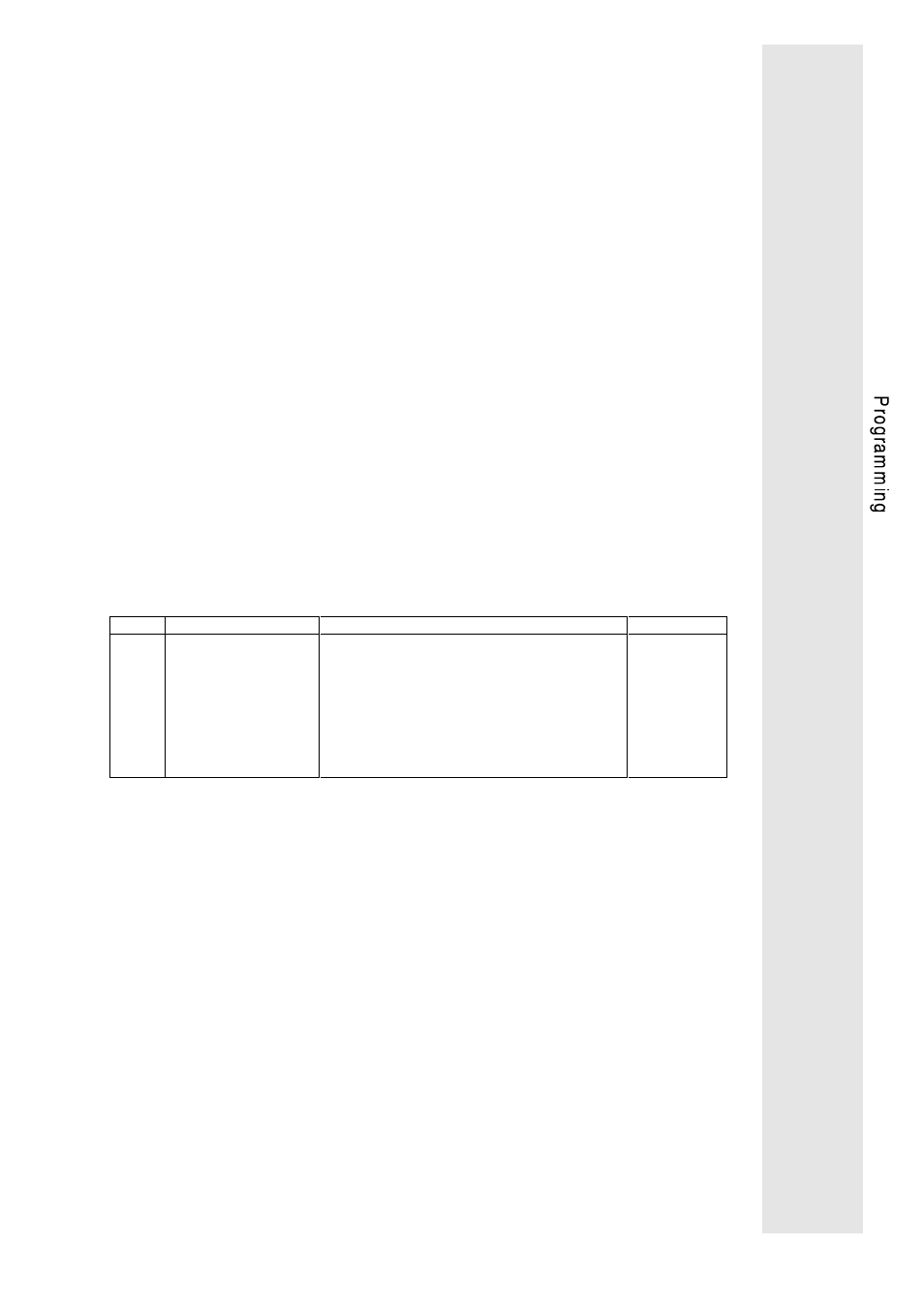

Code

Parameter

Meaning

Acceptance

C018

-0-

-1-

-2-

-3-

-4-

-5-

-6-

-7-

-8-

1kHz

2kHz

4kHz variable

6kHz variable

8kHz variable

12kHz variable

16kHz variable

12kHz fixed (for motor supply filter)

16kHz fixed (für motor supply filter)

[SH + PRG]