Lenze 8615E User Manual

Page 120

118

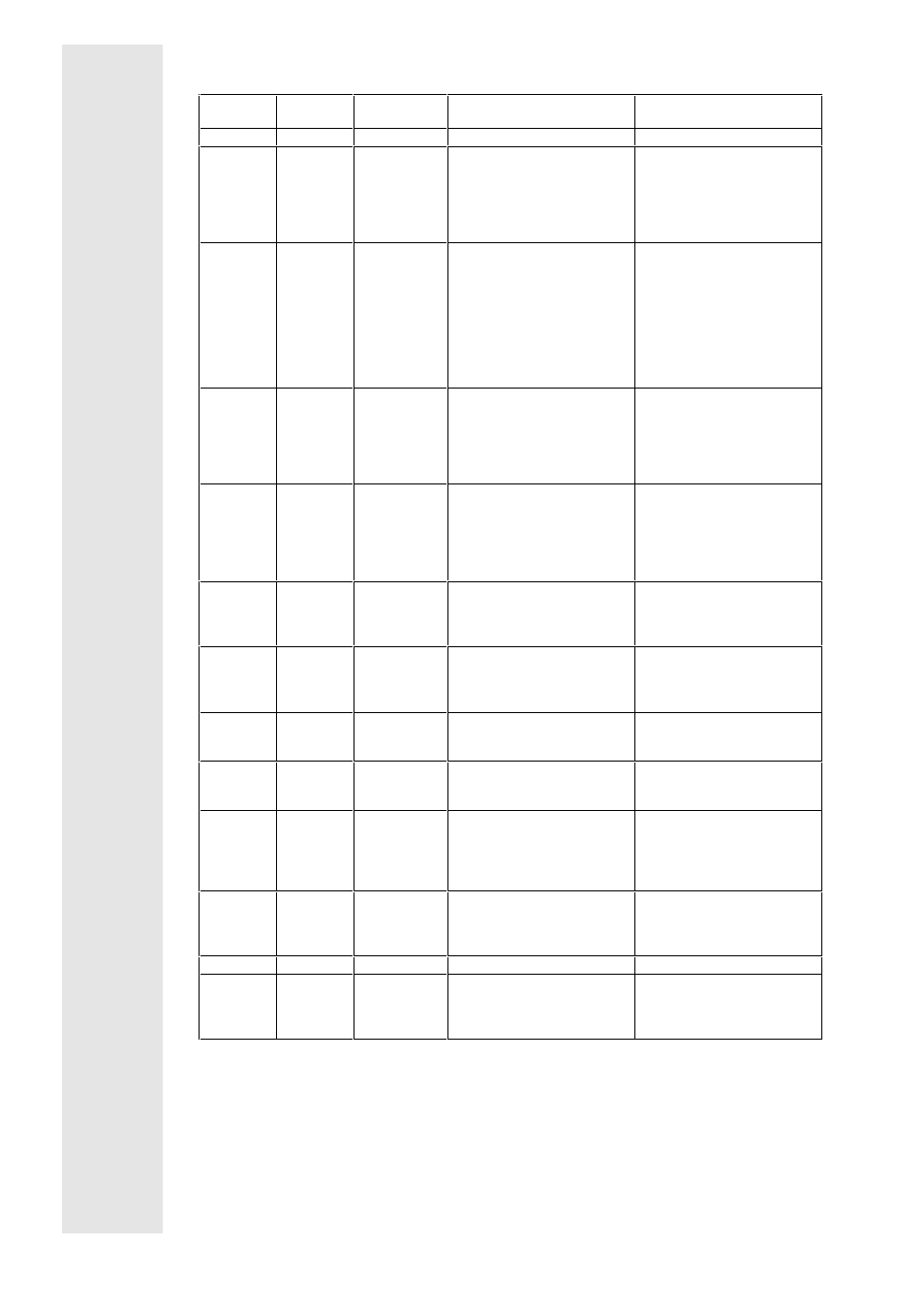

List of fault indications

Display on

keypad

Display on

host

Fault

Cause

Remedy

---

0

no fault

OC1

11

Short circuit/

˝Earth fault

Short circuit/earth fault at the

motor side e.g. by

- defective motor cable

- contact of motor windings

- contact between motor

housing and winding

Check motor cable for short-

circuit

Separate motor cable from

inverter and check insulation

between U-V-W and PE

Check motor

OC5

15

Inverter

overload

Frequent or too long

accelerations with overcurrent

Permanent overload with motor

current > 110% rated current.

The permissible output power

was reduced to 12 or 16 kHz by

increasing the chopping

frequency

Check dimensioning of the drive

If necessary, set I

⋅

t monitoring

(C119, C120) to increased or

maximum permanent power

(observe ambient temperature)

Check setting of the chopping

frequency (C018)

OC6

16

Motor overload Thermal overlaod of the motor,

caused by e.g.

- non-permissible continuous

current

- frequent or too long

accelerations

Check dimensioning of the drive

Enter correct motor size (C086),

if necessary, switch off

monitoring (C119, C120)

OH

50

Overheat

heatsink

Heatsink too hot, e.g. because,

- Ambient temperature too high

- Heatsink strongly polluted

- Incorrect mounting

Allow inverter to cool and

ensure a better ventilation

- Check ambient temperature in

the control cabinet

- Clean heatsink

- Change mounting

OH3

53

Overheat PTC

input

Motor is overheated

PTC connecting cable

interrupted

PTC input open

Check dimensioning of the drive

Check PTC connection

Bridge PTC input

CEO

61

Communication

error 0

Supply of automation module

switched off or defective

Connection to automation

module interrupted

Check supply

Check connecting cable

U15

70

±

15-V supply

defective

Overload/Short-circuit at

terminal 20

±

15-V supply defective

Check load at terminal 20

Return inverter to factory

CCr

71

System failure

Strong interferences on control

cables

PE loops in the wiring

Screen control cables

Check PE wiring and GND

Pr

72

Parameter

reset

After mains connection a

modified software version was

found.

Factory settings were loaded

automatically.

Set desired parameters and

save under C003.

Pr1...Pr4

72

Parameter

reset

When parameter sets 1 to 4

were loaded, a fault was found.

Factory settings were loaded

automatically.

Set desired parameters and

save under C003.

PEr

74

Program error

Contact factory

EER

91

External fault

Signal via digital input "fault

indication"

Incorrect programming of the

input "fault indication"

Check external feedback source

Check programming of the input

"fault indication"