7commissioning of the system – Lenze EtherCAT Controller-based Automation User Manual

Page 58

7

Commissioning of the system

7.3

Detailed description of the commissioning steps

58

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

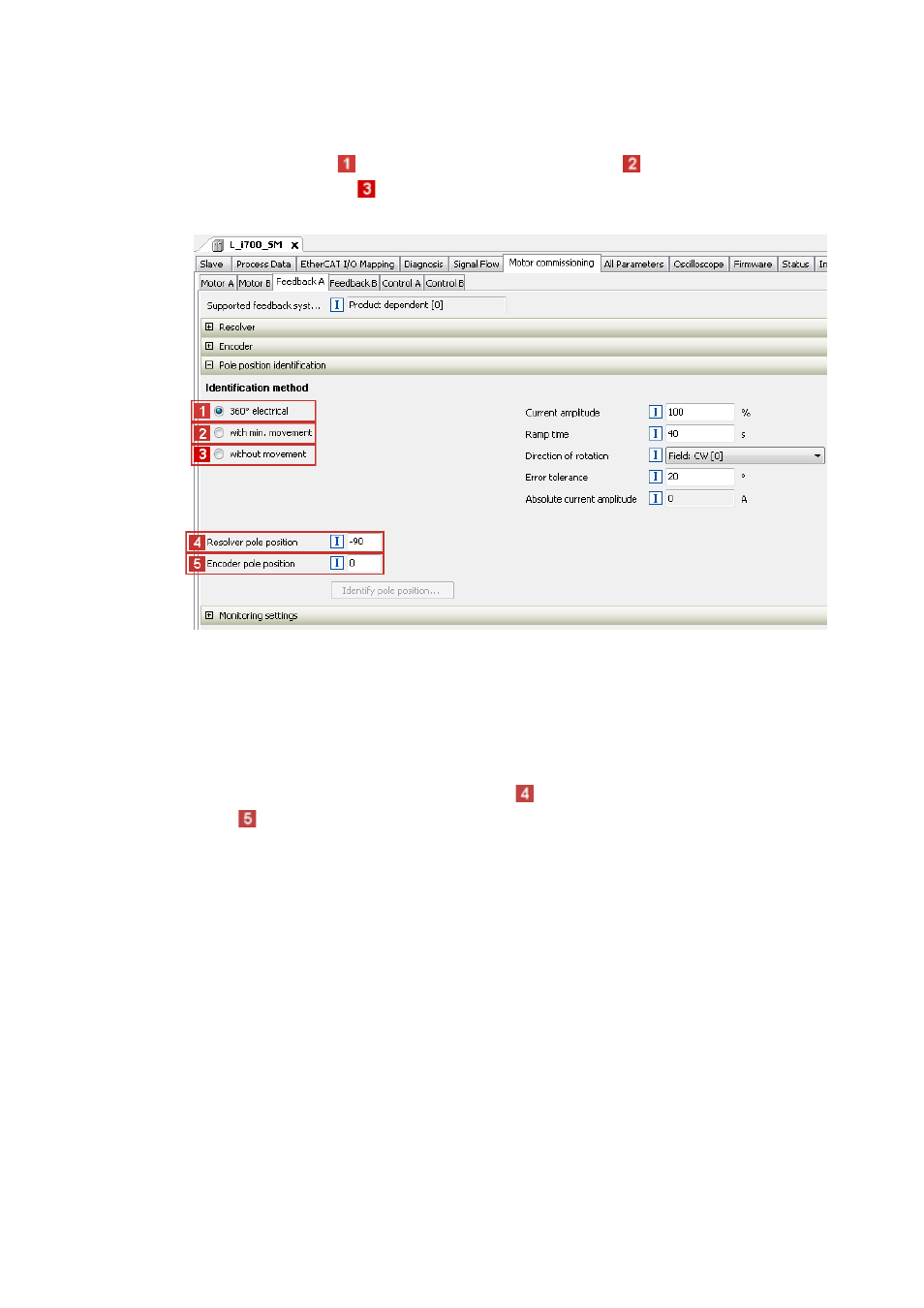

Either of the functions

Pole position identification for 360°,

Pole position identification

with min. movement and

Pole position identification without movement can be selected in

order to determine the pole position for the currently activated motor encoder:

The functions should deliver approximately the same result. Due to e.g. friction, bearing forces, and

a trapezoidal field curve, however, the results can differ from each other. Here the method with one

full revolution (360°) will provide the most precise results and the method without any movement

will provide the most inaccurate results. The precision of the results can be increased by increasing

the percentage of the current amplitude.

After successful completion of pole position identification ...

... the controller inhibit is set automatically and the

Resolver pole position (0x2C03/2 / 0x3403/

2) or the

Encoder pole position (0x2C03/4 / 0x3403/4) determined for the activated feedback

system is set.

• For permanent storage, the changed settings must be uploaded from the Servo-Inverter i700 to

the Lenze Controller.

The »EASY Starter« can be used to upload the parameters of the servo inverter and to save them

as a file. This file can then be imported to the »PLC Designer«.

• The controller inhibit automatically set by the procedure can be deactivated via the CiA402

control word (0x6040 / 0x6840).

If an error occurs

If an error occurs during pole position identification or if pulse inhibit becomes active (e.g. due to

short-term undervoltage), the procedure is ended with controller inhibit without the settings being

changed.

If the motor was braked or blocked during pole position identification, this is detected at the end of

a measurement and no changes are made.

If pole position identification is aborted, the reaction set in the object, namely 0x2C60/0x3460

(monitoring of pole position identification: reaction) is triggered (Lenze setting: Fault).