Warning – INFICON SQM-242 Thin Film Deposition Controller Card Software Operating Manual User Manual

Page 32

3 - 2

IP

N 07

4-

55

1-

P1

A

SQS-242 Operating Manual

WARNING

Care should be exercised to route cables as far as

practical from other cables that carry high voltages or

generate noise. This includes other line voltage cables,

wires to heaters that are SCR-controlled, and cables to

source power supplies that may conduct high transient

currents during arc down conditions

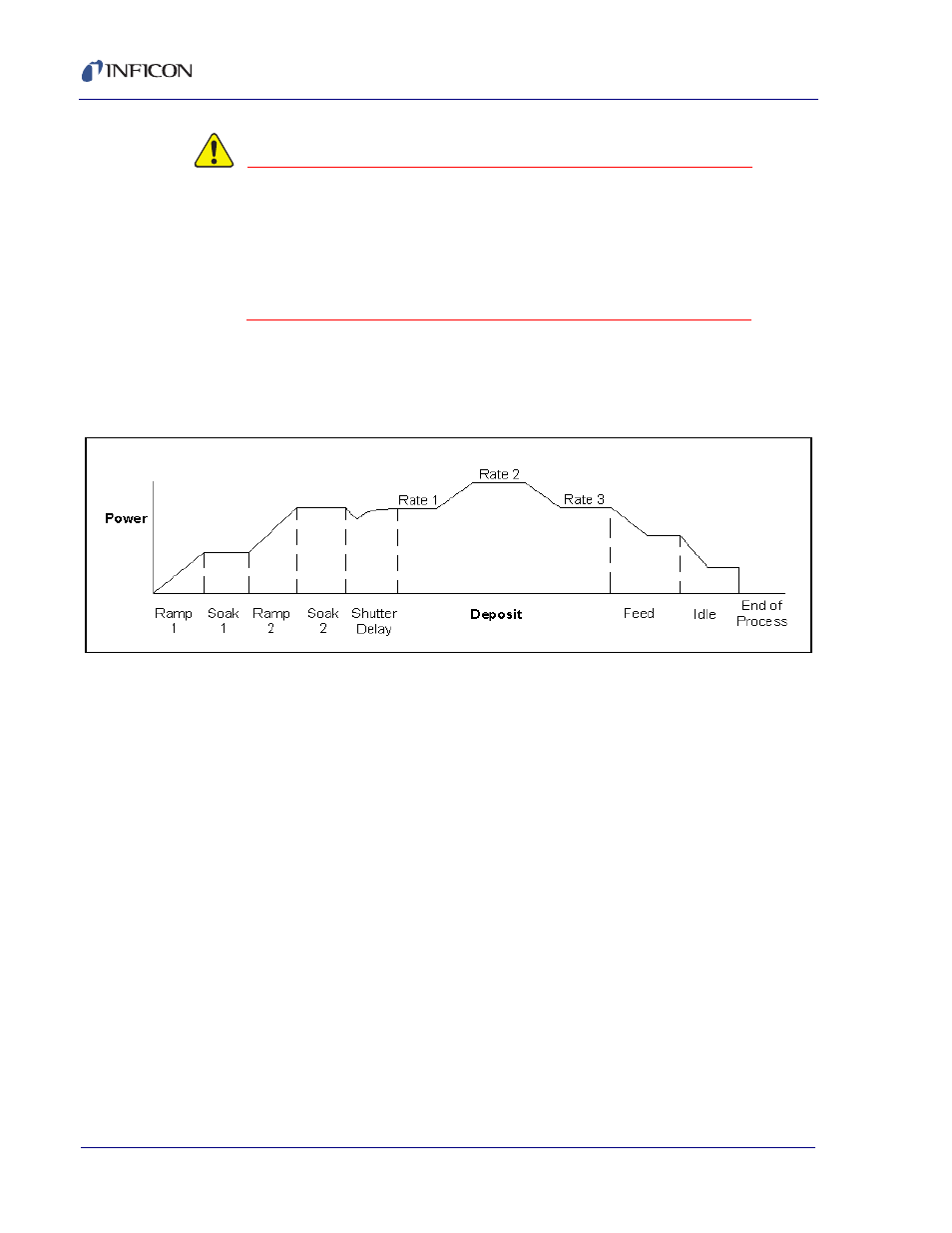

A typical deposition cycle for a thin film is shown in

broken into three distinct phases: pre-conditioning (ramp/soak), deposition, and

post-conditioning (feed/idle)

Figure 3-2 Typical Deposition Cycle

During pre-conditioning, power is applied to prepare the source material for

deposition. The first ramp/soak preconditioning phase is used to bring the material

to a uniform molten state. The second ramp/soak phase is typically set to a power

that is near the desired deposition rate.

When pre-conditioning ends, PID rate control of deposition begins. Initially, the

substrate material may remain shuttered until the desired deposition rate is

achieved (shutter delay). Once the control loop achieves the desired rate, the

shutter opens and deposition begins. Multiple deposition rates (rate ramps) can be

programmed.

When the desired thickness is reached, the evaporation source is set to feed or idle

power. At this point the process may be complete, or deposition of another film

layer may begin. Up to six separate films can be codeposited within a single layer.

There is no practical limit to the total number of processes, layers, or materials that

can be stored in the process database.