1 engine preventive maintenance – SkyTrak 6036 Service Manual User Manual

Page 88

Section 8.

Engine

8-2

Model 6036 S/N 9B0499 and Before

8.1

ENGINE PREVENTIVE

MAINTENANCE

8.1.1 Daily Before Operation

1.

Open fuel fill access door with a key, Fig. 8.1.

2.

Remove fill cap on fuel tank and fill with No. 2

Diesel Fuel as required. Tank capacity is 24

gallons (90 liter).

3.

Install fill cap and lock access door.

8.1.2 First 50 Hours and 250 Hours

Thereafter

NOTE: Refer to paragraph 8.1.9 for 25 or 50 hour

Post Delivery Check.

Fan Belt Tension

1.

Lower carriage to ground, shut off engine, and

engage park lock.

2.

Unlock and open left rear engine access door.

3.

Inspect the fan belt. Replace a cracked or

frayed belt.

Fig. 8.1 Fuel Fill Access Door

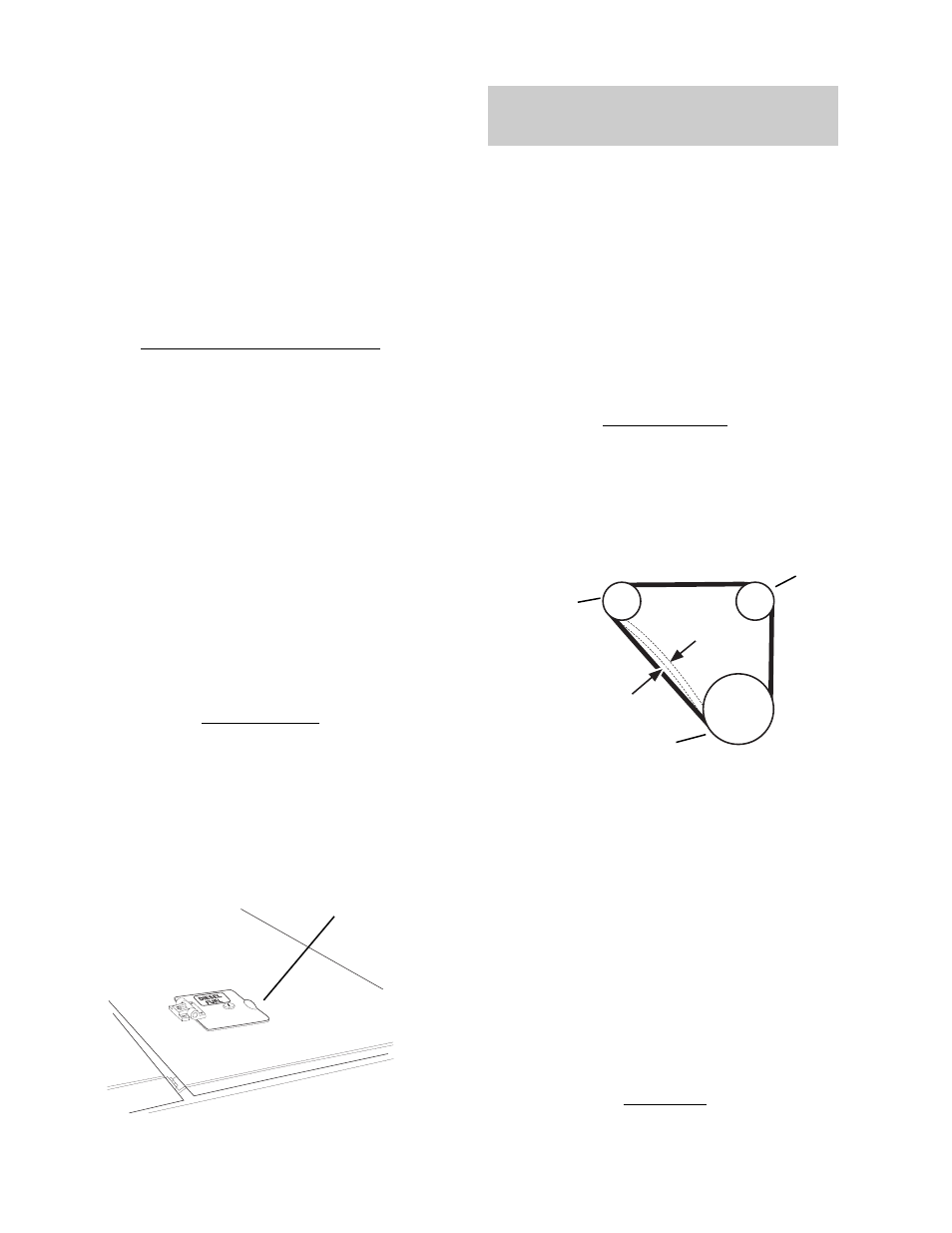

Fig. 8.2 Fan Belt Deflection

4.

Check fan belt tension midway between the

crankshaft and alternator pulleys, Fig. 8.2.

Deflection should be 1/4 to 3/8" (6 to 9 mm)

with an applied force of 13 to 15 lbs. (6 to 7

kg).

5.

If belt deflection exceeds the tolerance, loosen

both alternator mounting screws. Carefully pry

the alternator to tighten the belt and, at the

same time, tighten the alternator screws.

Recheck belt deflection.

6.

Close and lock the left rear engine access

door.

8.1.3 Daily or 10 Hour Intervals

Air Cleaner

1.

Lower carriage to ground, shut off engine, and

engage park lock.

FAN PULLEY

ALTERNATOR

PULLEY

1/4 TO 3/8 "

(6 TO 9 mm)

BELT DEFLECTION

CRANKSHAFT PULLEY

IMPORTANT: These instructions cover only the

routine maintenance of the engine. Refer to your

Perkins Engine Distributor for engine diagnosis,

repair and component replacement.

A gradual running in of a new engine is not

necessary. Full load can be applied to a new

engine as soon as the engine is put into service

and the coolant temperature is at least 140 °F

(60 °C). Extended light load operation during the

early life of the engine is not recommended. Do

not run engine at high no load speeds. Do not

apply an overload to the engine.

FUEL FILL ACCESS

DOOR

Standard Maintenance Practices

It is assumed that gaskets will be replaced and

gasket faces will be cleaned, where applicable.

It is understood that in reassembly and inspection,

all parts are to be thoroughly cleaned, and where

present, burrs and scale are to be removed.

It follows that any open ports of high precision

components such as fuel system equipment,

exposed by removal or disassembly, will be

covered until reassembled to prevent the entry of

foreign material.

Use a suitable sealant such as Loctite

®

when

installing screws into " through" holes into the

interior of the engine.

NOTE: Screw threads which have been sealant

coated can be identified by their red or blue etc.

color.

Unified Threads

All threads used on the engine are Unified Series

and American Pipe Series.

Unified threads are not interchangeable with BSF

and although BSW have the same number of

threads per inch as Unified Coarse Series, inter-

changing is not recommended, due to a difference

in thread form.

OA1130

OA0362