SkyTrak 6036 Service Manual User Manual

Page 178

9-65

Model 6036 S/N 9B0499 and Before

Section 9.

Hydraulic System

12. Slide the driven gear and shaft through the

housing (15) and into the bushing in the shaft

end cover (16). Coat the steel sleeve tool

(Fig. 9.41) with hydraulic oil inside and out.

Place the lightly lubricated drive shaft inside

the sleeve and slide both through the shaft

end cover with a twisting motion until the

integral gear rests against the thrust plate.

Avoid damaging the double lip seal (17).

Squirt clean hydraulic oil over the gears.

13. Slip thrust plate (8) with seal (7) over gear

journals and into housing bore. The flat side

of the seal should face up with the relief

groove facing the outlet side.

14. Position the bearing carrier housing (13) over

the gear housing (15) so that the bushings

receive the journals of the drive and driven

gears. Be sure to line up dowel pins with the

dowel holes

15. Insert the connecting shaft (10) into the spline

of the drive gear shaft. Position the second

gear housing (12) on the bearing carrier

housing as described in step 8.

16. Place the thrust plate (8) with seal (7) in the

gear housing as described in step 11. Insert

the drive and driven gears of the second

section gear set (9) in their respective bear-

ings. Make certain the gears are in contact

with the face of the thrust plate.

17. Slip thrust plate (8) with seal (7) over gear

journals and into housing bore. The flat side

of the seal should face up with the relief

groove facing the outlet side.

18. Place port end cover (4) over the gear jour-

nals. Align the dowel pins (5) with the holes in

the mating casting. Being careful not to pinch

the gasket seal (11), tap the port end cover

lightly in the center between bearing bores to

engage the dowels and to move parts together

in a final seating.

Fig. 9.43 Channel Seal Installation

NOTE: If new plugs are being installed, coat

threads with Loctite

®

Threadlocker 242.

5.

If removed, install new dowels (5) as needed.

Be sure dowel holes are clean and free of

burrs. Gently tap in new dowels with a soft

hammer.

6.

Assembly of bushings in shaft end cover (16),

bearing carrier housing (13) and port end

cover (4).

a.

Install any new bushings in drive bores

with groove to top of unit (12 o’clock).

Assemble bushings in driven bores with

the groove to bottom of unit (6 o’clock).

b.

Press bushings into the bores, one at a

time using the special installation tool (Fig.

9.40) and an arbor press. Be sure the

grooves are positioned as stated in step

6a. Bushings must be pressed into the

bores flush with the casting face. Be sure

to support the castings so they are square

and level.

c.

Repeat Steps 1 and 3 (stone and rinse

parts).

7.

Before inserting a new lip seal (17) in the shaft

end cover (16), coat the outer edge of the lip

seal and its recess with Permatex Aviation

Form-A-Gasket No. 3 non-hardening sealant

or equivalent. With the metal side of the lip

seal up, press it into the mounting flange side

of the shaft end cover with an arbor press and

special installation bar (paragraph 9.4.2b). Be

careful not to damage the lip of the seal.

Press in until flush with the recess. Wipe off

excess sealant.

8.

Lubricate new gasket seals (11) and insert

them into the grooves in both sides of all gear

housings.

9.

Position the first gear housing (15) over the

shaft end cover (16) and dowels. Tap it with a

soft hammer until it rests tightly against the

shaft end cover. Be careful not to pinch the

gasket seal (8). Also be sure the large

rounded core is on the inlet side

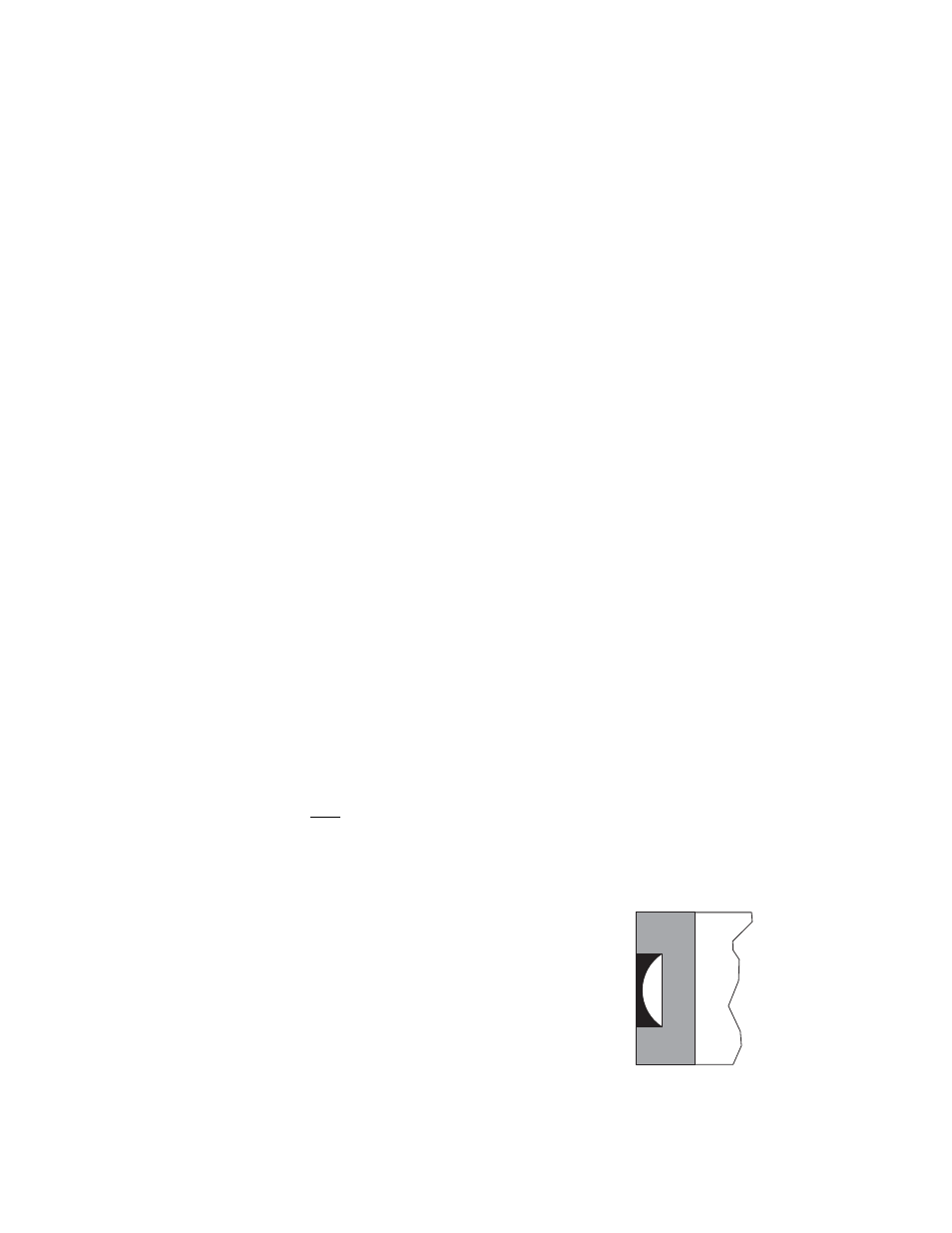

10. Assemble new channel seals (7) into the

grooves in all the thrust plates (8) with the flat

side of the seal facing away from the thrust

plate (Fig. 9.43).

11. Gently slip thrust plate (8) with seal (7) through

the gear housing and into place on the shaft

end cover (16). The channel seal should face

the shaft end cover. The relief groove in the

plate should face the outlet side of the pump.

THRUST PLATE

FLAT SIDE

OF SEAL

MA0831